Automatic flattop chain production device and production method

An automatic production and chain technology, applied in the direction of metal chains, etc., can solve problems affecting the stability of the chain, chain deviation, etc., to achieve the effect of improving the stability of work, reducing production costs, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

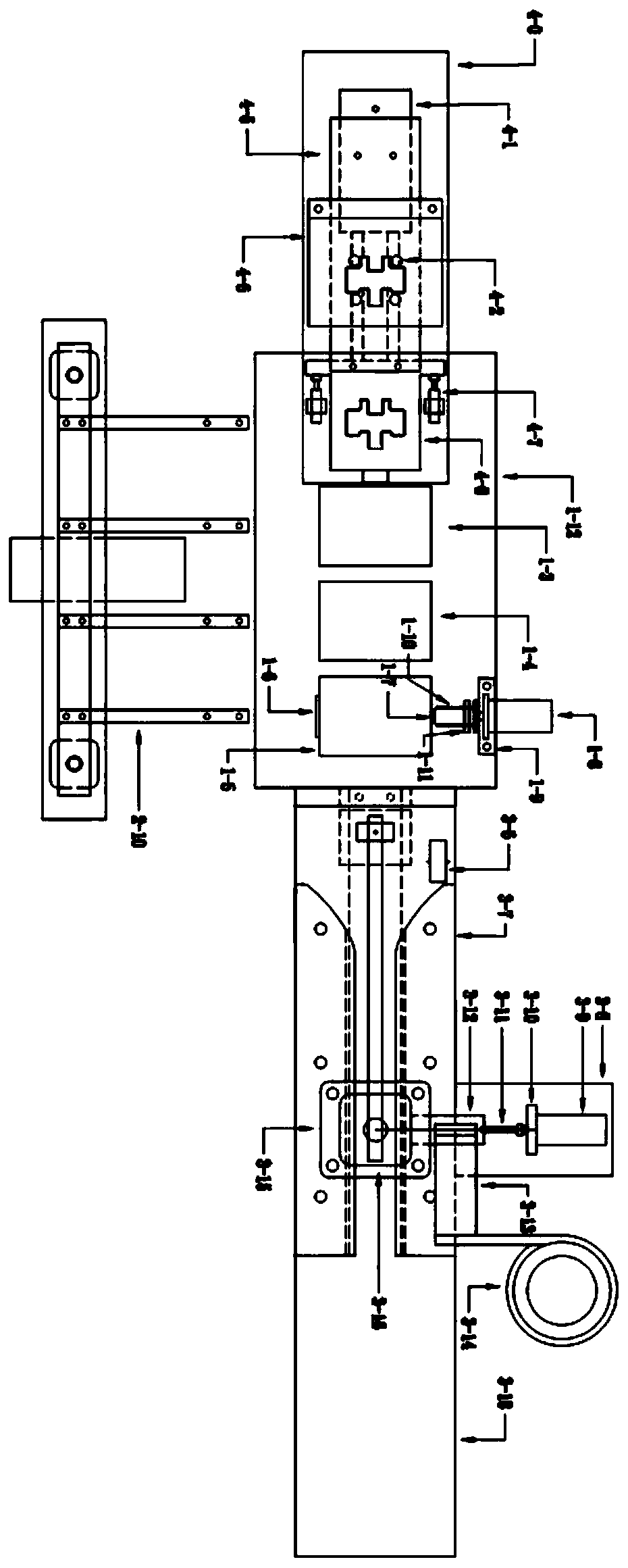

[0060] Attached below Figure 1-2 The present invention is further described with embodiment:

[0061] An automatic production device for flat-top chains, comprising a molding die 1, a manipulator mechanism 2, a chain assembly mechanism 3, and a material storage mechanism 4 arranged from upstream to downstream along the flat-top chain forming and assembling process;

[0062] The forming die 1 is used for forming the chain plate of the flat top chain;

[0063] The manipulator mechanism 2 is used to move and place the chain plate of the flat top chain;

[0064] The chain assembly mechanism 3 is used for the assembly of the flat top chain;

[0065] The storage mechanism 4 is used for coding and feeding the flat-top chain raw materials.

[0066] In this example, if Figure 1-2 As shown, the forming die 1 includes a hydraulic punch press 0-0, a pre-folding upper die 1-0, a bending upper die 1-1, a rolling die 1-2, a pre-folding lower die 1-3, a bending lower die Mold 1-4, Roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com