A textile equipment with automatic covering, protective cleaning function

A kind of textile equipment and clean technology, applied in the direction of textile, textile and paper making, looms, etc., can solve the problems of adhesion, polluted cloth, poor environmental management, etc., to achieve the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

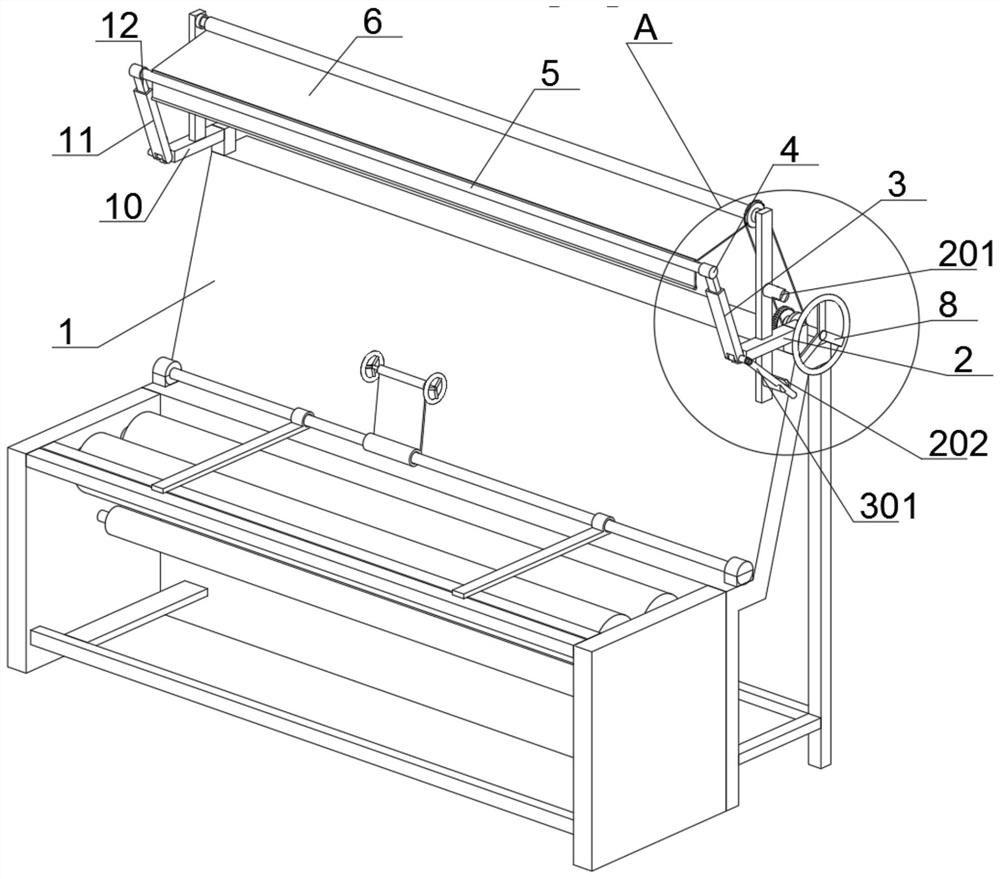

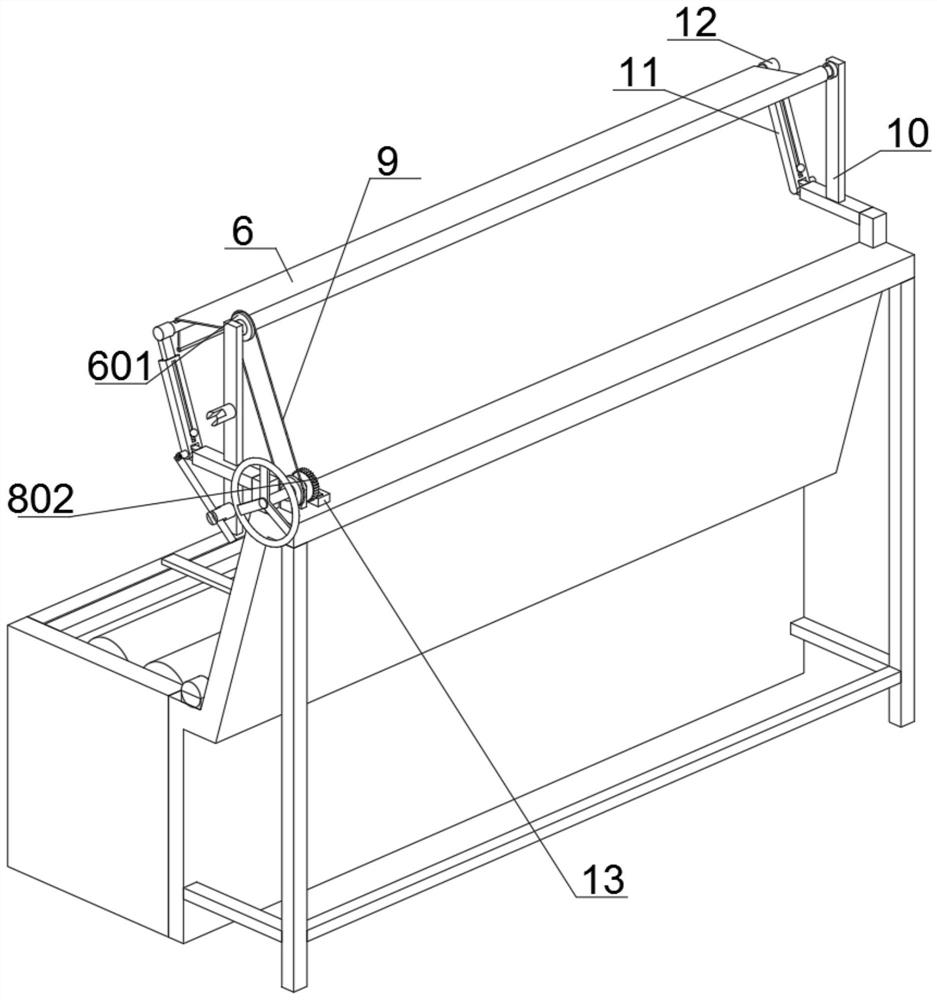

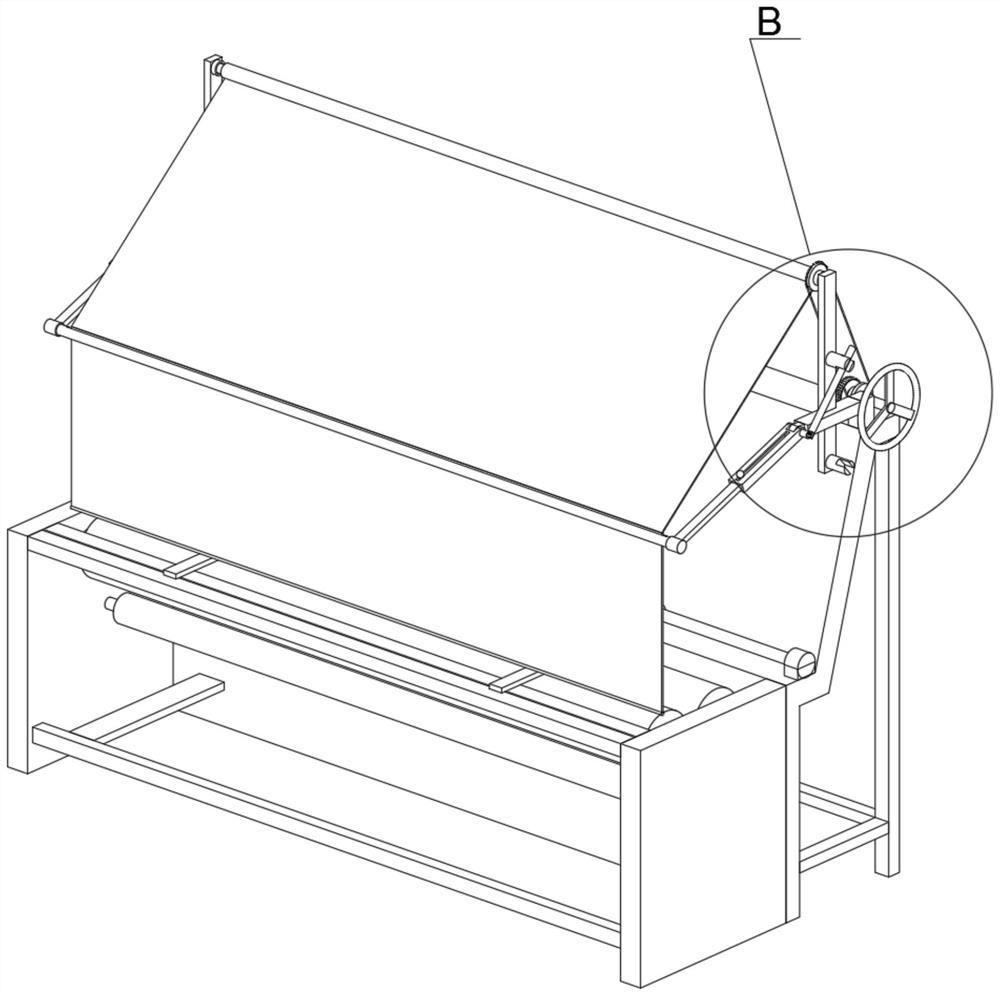

[0037] as attached figure 1 to attach Figure 10 Shown:

[0038] The present invention provides a textile equipment with the function of automatic covering, protection and cleaning, including a textile machine 1, a right sliding frame 3, a reversing handle 301, a right sliding rod 4, a clamping rod 5, a cord 6, a hand mechanism 8, and a left frame body 10, block 13; the upper right side of the back plate of the textile machine 1 is connected to the right frame body 2 by welding, and the left frame body 10 is connected to the left side by welding on the upper left side of the back plate of the textile machine 1; the right carriage 3 is connected by hinges In front of the right frame body 2; the left frame body 10 is connected to the front of the left frame body 10 by hinges; the right slide bar 4 is slidably connected to the right slide frame 3, and the left slide bar 12 is slidably connected to the left slide frame 11, The right slide bar 4 includes a gear head 401. The righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com