Sunken prefabricated cabin base

A prefabricated cabin and frame technology, which is applied in the directions of busbar/line layout, electrical components, substation/switch layout details, etc., can solve the problems of heavy on-site workload, complex structure of prefabricated cabin, high height of base and cabinet base, and achieve simple production , high utilization rate of structural space and effect of height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

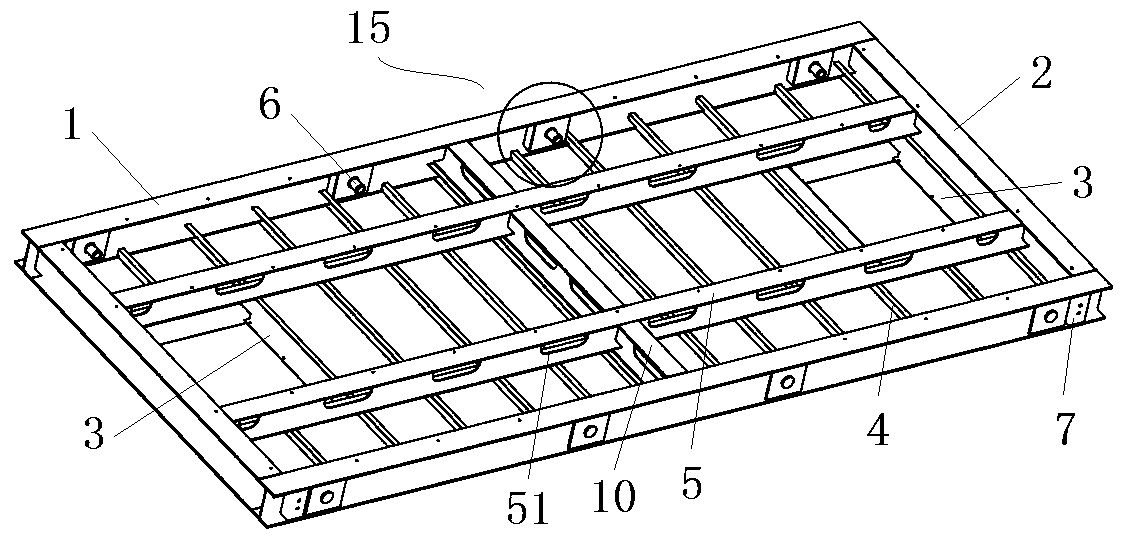

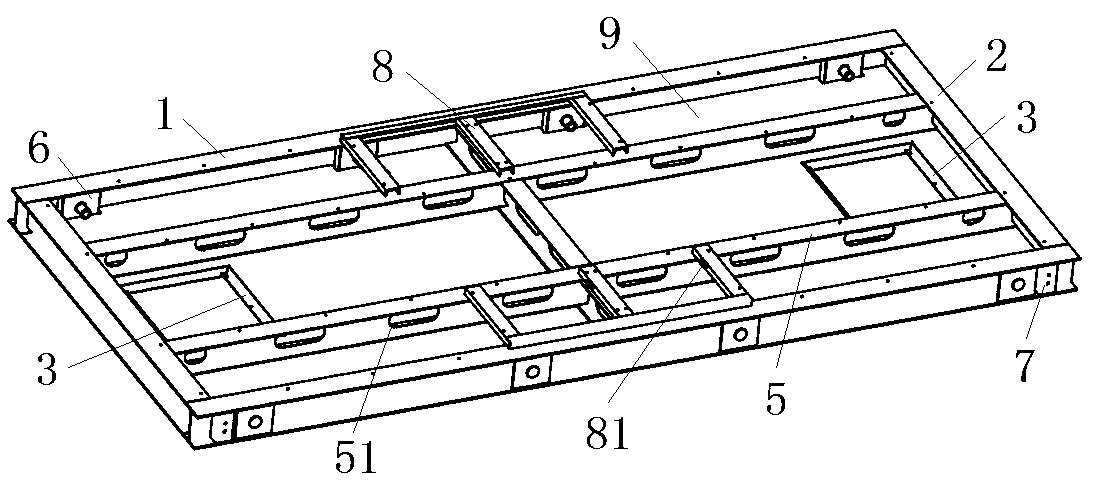

[0031] Embodiment 1 of the sunken prefabricated cabin base of the present invention is as Figure 1 to Figure 5 As shown, it includes two beams 1 arranged side by side and a longitudinal beam 2 that is perpendicular to the two beams 1 and connects the two beams 1. The beam 1 and the longitudinal beams 2 form a frame. The internal longitudinal beams 10 arranged at intervals, the internal longitudinal beams 10 are provided with routing holes 51 at intervals along the axial direction, and the internal transverse beams 5 parallel to the transverse beams 1 and arranged at intervals are also arranged in the frame, and the side walls of the internal transverse beams 5 are provided with The wiring hole 51, the wiring hole 51 can also reduce the weight of the sunken prefabricated cabin base.

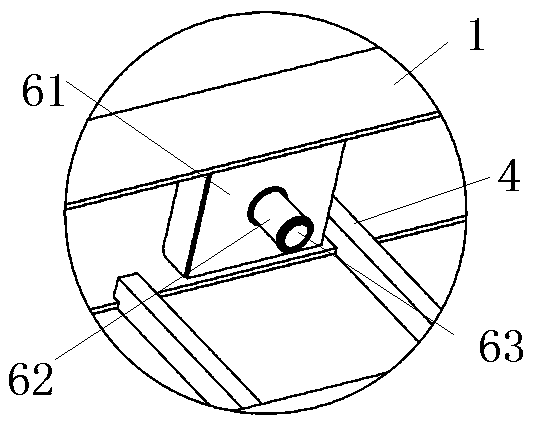

[0032] Between the two beams 1, there is a support frame 4 parallel to the longitudinal beam 2 and arranged at intervals. The support frame 4 is arranged near the bottom surface of the beam 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com