A kind of magnesium oxide expansion agent activity evaluation method

An evaluation method, magnesium oxide technology, applied in the direction of material thermal development, etc., can solve the problem that the low active components of magnesium oxide expansion agent do not reflect the hydration activity of magnesium oxide expansion agent, and achieve the effect of predicting the expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

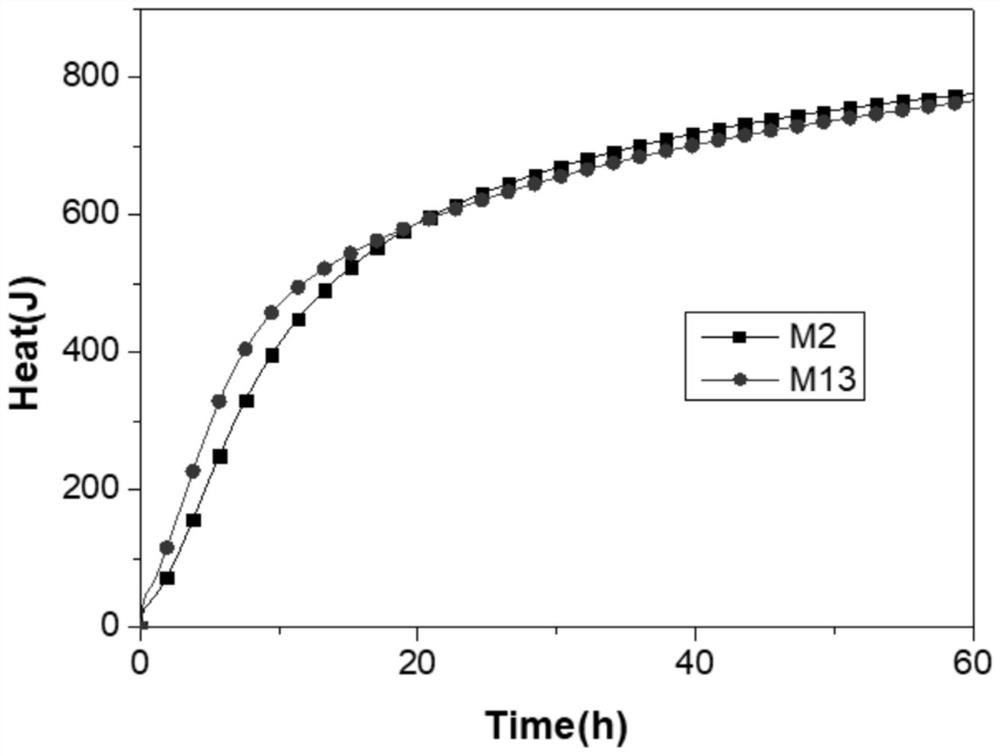

[0036] Take the magnesium oxide M1, M2, M3 obtained by calcining different varieties of magnesium carbonate, and calculate the reference standard water consumption M 水=10+1*0.94 / 4.18=10.2249. Weigh 10.2249 g of deionized water into ampoule B, weigh 10 g of deionized water into ampoule A, and weigh 1 g of M1 magnesium oxide powder sample with weighing paper. Mix bottle A with magnesium oxide powder and shake well, open the software, click "Mark", then put bottle B and bottle A at a time to start the test. The same operation test M1, M2, M3 magnesium oxide expansion agent powder samples. After 24 hours, the obtained data is plotted with origin, such as figure 1 shown:

[0037] Take the hydration heat release of three different magnesia expansion agents at t=24h. Q1=908.74J, Q2=625.79J, Q3=319.33J, so the average heat release per unit time in 24h is q1=37.86(J / h), q2=26.07(J / h), q3=13.3(J / h) Therefore, three types of magnesium oxide are divided into: type 1 magnesium oxide e...

Embodiment 2

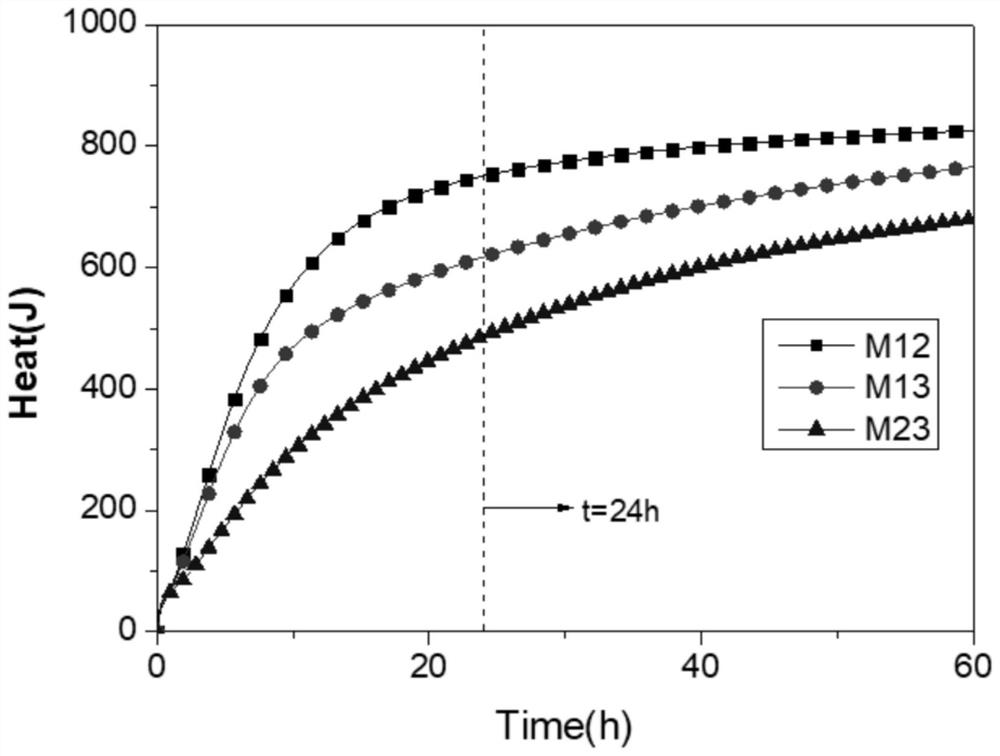

[0039] The three kinds of magnesium oxides M1, M2 and M3 were mixed in 1:1 mass percentage, and mixed for 2 minutes with a three-dimensional motion mixer, so that the two kinds of magnesium oxides could be mixed uniformly, and were numbered M12, M13, M23 respectively. The three kinds of magnesium oxides obtained by mixing are operated in the same manner as in Example 1, and the hydration heat curve obtained by the test is as follows: figure 2 shown:

[0040] Take the hydration heat release of three different magnesia expansion agents at t=24h. Q12=750.88J, Q13=617.33J, Q3=487.43J, so the average heat release per unit time in 24h is q12=31.29(J / h), q13=25.72(J / h), q23=20.3(J / h) Therefore, the three types of magnesium oxide after mixing are divided into: 12 types of mixed expansion agent are high-activity magnesium oxide, and types 13 and 23 are mixed with medium-activity magnesium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com