Detection method for concrete pouring elevation in underground bored cast-in-place pile hole

A technique of bored cast-in-place piles and detection methods, which is applied in the direction of sheet pile walls, foundation structure tests, construction, etc., can solve the problems of concrete waste, difficulty, and influence on the overall construction progress, and achieve the effect of precise control of pouring elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

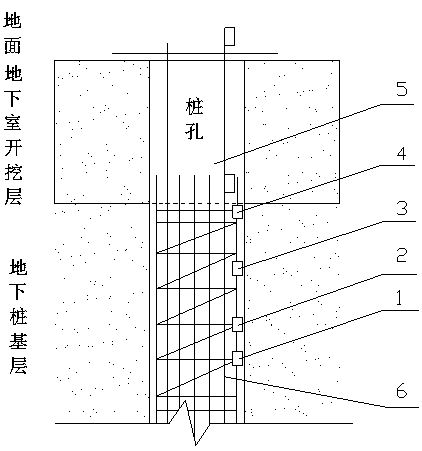

[0021] like Figure 1-2 As shown, a method for detecting the concrete pouring level in the hole of the underground bored pile, the specific steps are as follows:

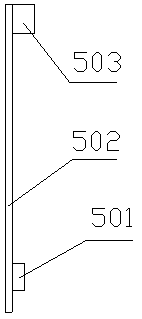

[0022] 1) Installation of direct detection equipment: when the reinforcement cage 6 is finished and lowered to the last section, a specific gravity detection is installed on the upper end of the reinforcement cage 6 on the ground (specifically, on the main reinforcement of the reinforcement cage 6 connected with the hanging bars in the later stage). device and three conductivity detection devices, of which the top conductivity detection device is located at the level where the concrete needs to be poured later; figure 1 As shown, a specific gravity detection device 1, a first conductivity detection device 2, a second conductivity detection device 3 and a third conductivity detection device 4 are arranged from bottom to top on the reinforcement cage 6, wherein the specific gravity detection device 1 is used for concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com