Method for preventing trash holding device from being attached to and wound by sewage

A technology of dirt and trash racks, which is applied in the field of hydraulic structure trash control equipment, can solve the problems of rotary mechanical device dirt stuck, difficult to determine the size and structure of dirt cleaning teeth, and increase operating costs, so as to avoid further waste The effect of increased water hydraulic loss, good industrial application value, and eliminating the need for cleaning procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

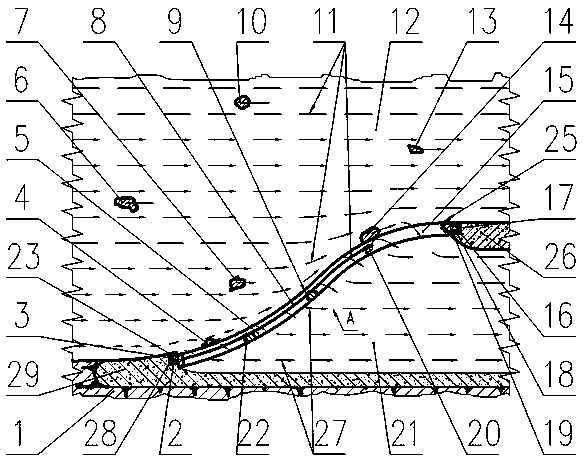

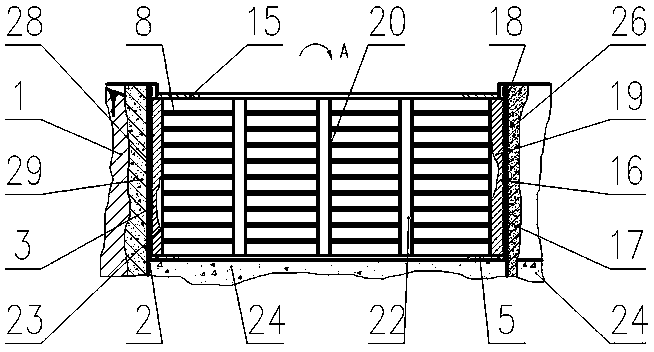

[0032] A method to prevent the grid-type trash-stopping device of the river channel water inlet from being attached and entangled by dirt, such as figure 1 As shown, including grid type trash rack 20 and auxiliary facilities: upstream grid pier 2 and downstream grid pier 17, grid type trash rack 20 is composed of grid bar 8, supporting beam 22, upper beam 15, lower beam 5, upstream The side beam 23 and the downstream side beam 19 are composed, the upstream grid pier 2 is composed of the upstream grid groove 28 buried on the upstream grid pier 2 and the upstream grid pier body 29, and the downstream grid pier 17 is composed of the downstream grid pier buried on the downstream grid pier 17. Groove 18 and downstream pier body 26 are formed. Such as figure 2 As shown, the upstream end of the grid-type trash rack 20 is inserted into the upstream grid groove 28 buried on the upstream grid pier 2 through the upstream flange 3 of the upstream side beam 23, and the downstream end of ...

Embodiment 2

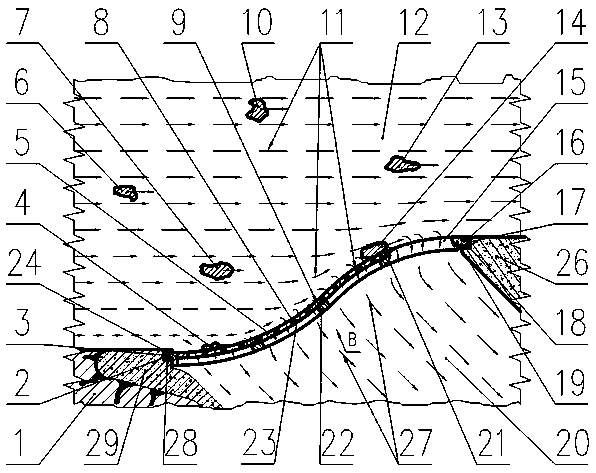

[0043] A method to prevent the orifice-type sewage blocking device of the river channel water inlet from being attached and entangled by dirt, such as image 3 As shown, it includes orifice type trash rack 21 and ancillary facilities: upstream grid pier 2 and downstream grid pier 17. 24 and the downstream side beam 19, the upstream grid pier 2 is composed of the upstream grid groove 28 buried on the upstream grid pier 2 and the upstream grid pier body 29, and the downstream grid pier 17 is composed of the downstream grid groove 18 buried on the downstream grid pier 17 and the downstream pier body 26. Such as Figure 4As shown, the upstream end of the orifice trash rack 21 is inserted into the upstream grid groove 28 of the upstream pier 2 through the upstream flange 3 of the upstream side beam 24, and the downstream end of the orifice trash rack 21 passes through the downstream side of the downstream side beam 19. The flange 16 is inserted into the downstream grid groove 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com