Convenient-to-use cable rack for cable laying

A cable laying and cable rack technology, applied in the field of cable racks, can solve problems such as low work efficiency and troublesome operation, and achieve the effect of improving work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

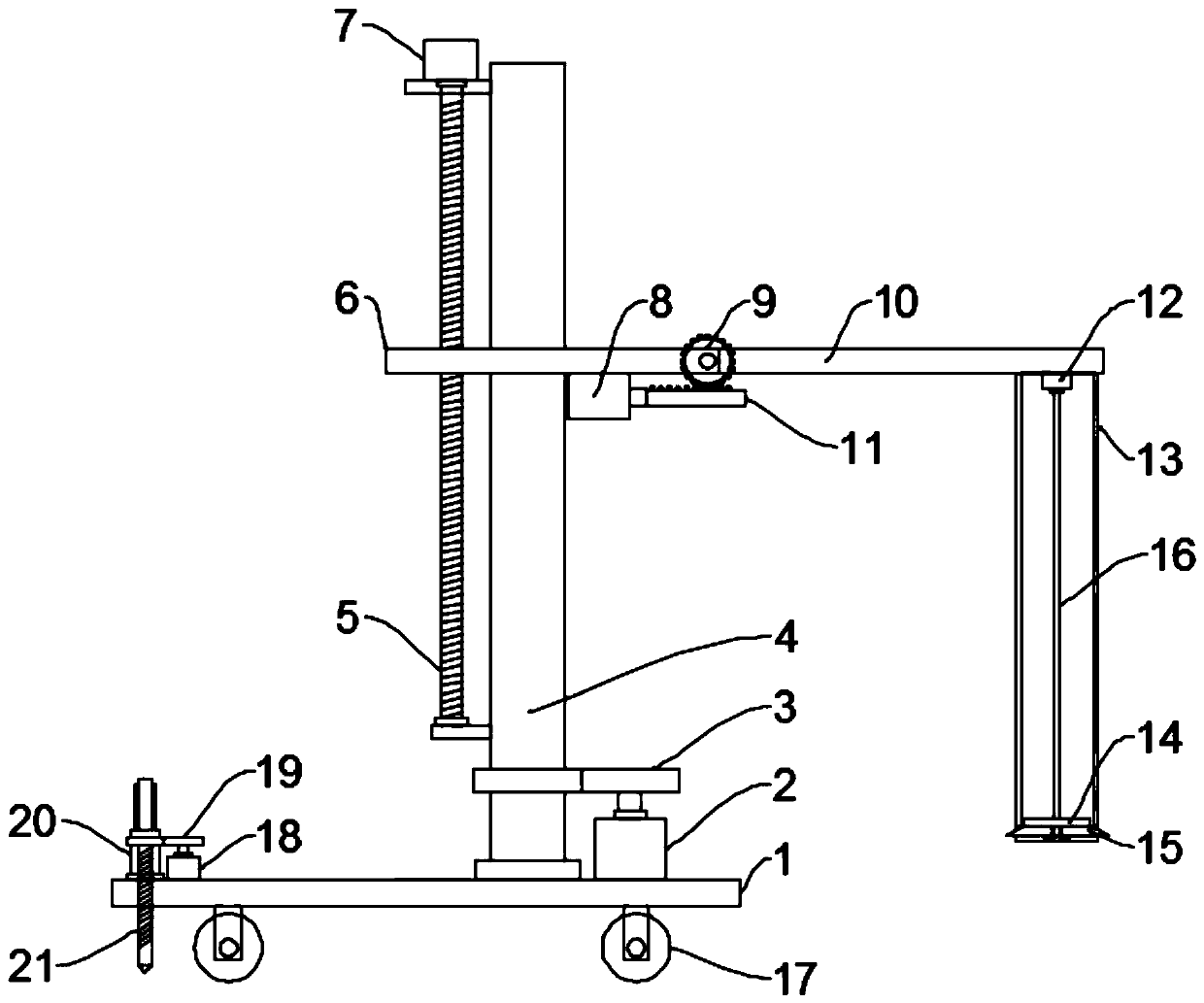

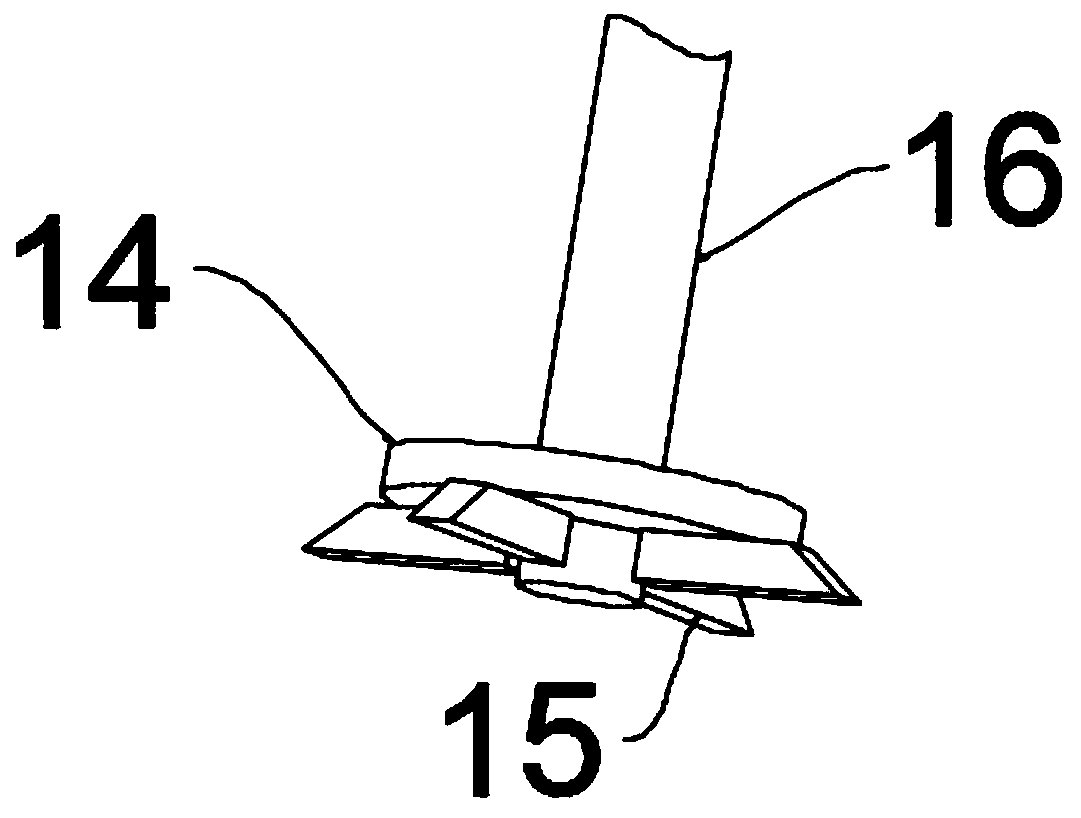

[0024] see Figure 1~2 , in an embodiment of the present invention, a cable rack that is convenient to use for laying cables includes a base plate 1, a mounting column 4 mounted on the base plate 1, and a support unit installed on the mounting column 4 for supporting the cable tray, the base plate 1. Rollers 17 are evenly and symmetrically fixed on the bottom, and the rollers 17 are self-locking rollers, which facilitate the movement of the device. A fixing mechanism for connecting and fixing with the ground is installed on the bottom plate 1. The fixing mechanism includes a second motor 18, The second gear pair 19, the drive sleeve 20 and the threaded drill rod 21, the upper surface of the base plate 1 is rotatably mounted with the drive sleeve 20, the drive sleeve 20 is pierced with a threaded drill rod 21, and the threaded drill rod 21 runs through the base plate 1 and extend to the bottom of the base plate 1, the threaded drill rod 21 is threadedly connected with the base ...

Embodiment 2

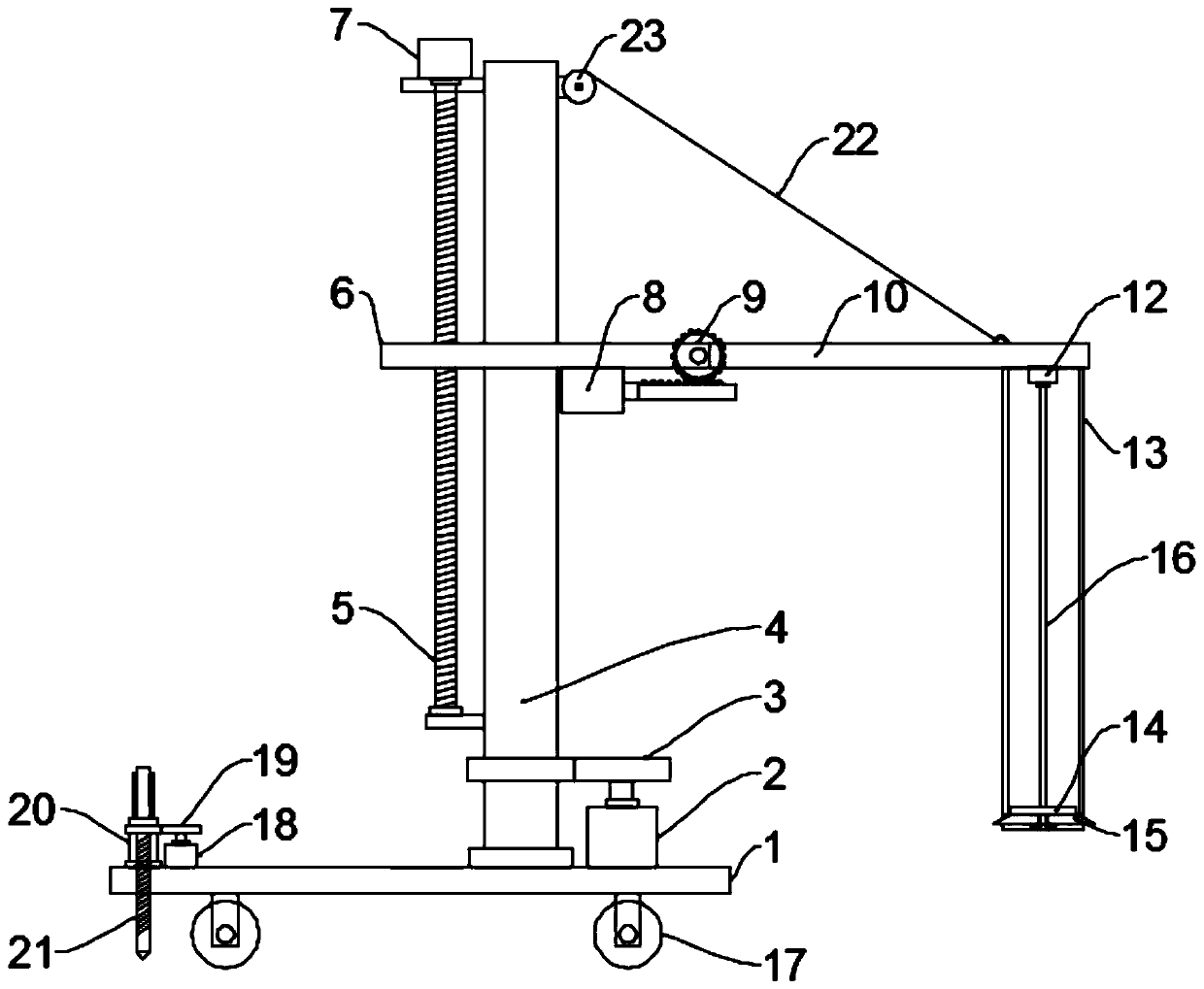

[0027] see image 3The difference between this embodiment of the present invention and Embodiment 1 is that, in order to ensure the safety and stability when adjusting the working angle of the cable reel through the adjustment mechanism, a hoist 23 is fixedly installed on the top of the installation column 4, and a hoist 23 is fixed on the top of the hoist 23. A traction rope 22 is coiled, and the other end of the traction rope 22 is tied to the end of the mounting plate 10, and the winch 23 cooperates with the adjustment mechanism to improve stability.

[0028] The working principle of the present invention is: when working, at first, move the device to the side of the cable reel, fix the device through the fixing mechanism, and then drive the supporting column 13 into the middle hole of the cable reel until the supporting column is driven by the lifting mechanism. 13 moves to the bottom of the cable reel, and then starts the fourth motor 12, the fourth motor 12 drives the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com