An inspection well tamping device for engineering

A tamping device and a technology for inspection wells, which are applied in the directions of infrastructure engineering, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of tamping work of side walls and bottom ends of installation pits that cannot be inspected, poor tamping effect, poor tamping effect, etc. Affect the compaction effect and other issues, and achieve the effect of good compaction effect, high compaction efficiency and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

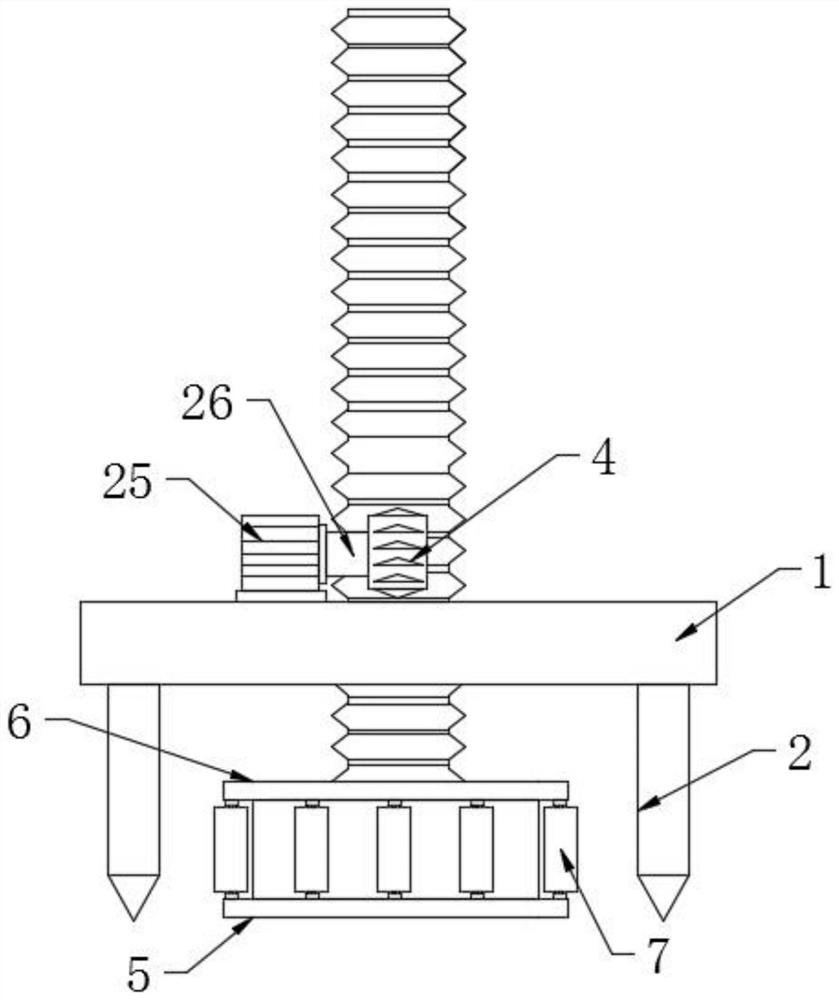

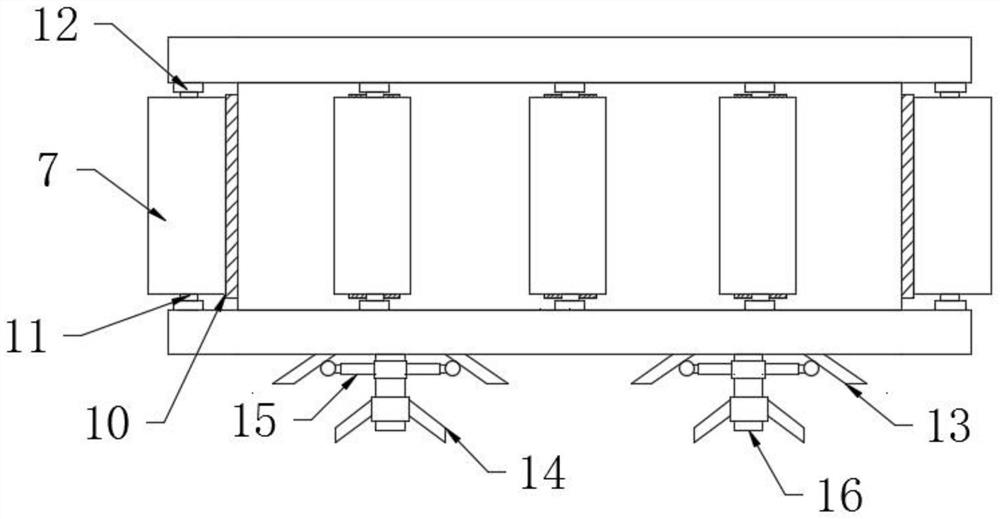

[0027] Such as Figure 1-5 As shown, the present invention provides a technical solution: an inspection well tamping device for engineering, including a base 1, a lifting worm 3, a driving gear 4, a tamping assembly, a first compacting mechanism, a second compacting mechanism and a crushing mechanism 9. The lifting worm 3 runs through the base 1 and is rotationally connected with the base 1. The driving gear 4 is located on the upper surface side of the base 1, and the driving gear 4 is meshed with the lifting worm 3. The tamping assembly is located on the base Below the seat 1 and fixedly connected with the lifting worm 3, the first compacting mechanism is located at the lower end of the compacting assembly, the second compacting mechanism is located at the side wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com