Food precise quantifying and packing production line

A quantitative packaging and production line technology, applied in packaging, transportation packaging, food packaging, etc., can solve the problems of reduced production efficiency, incoherent production line beats, large packaging error range, etc., and achieve the effect of reducing weighing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

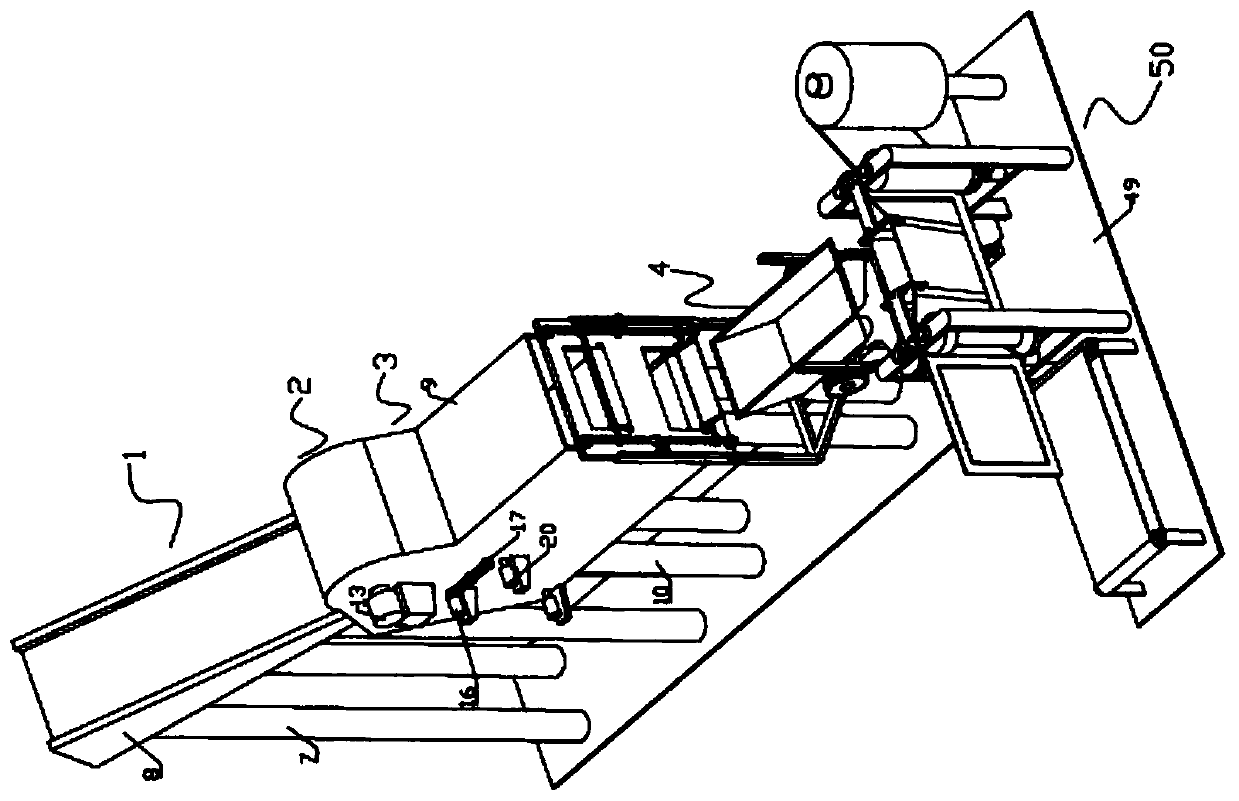

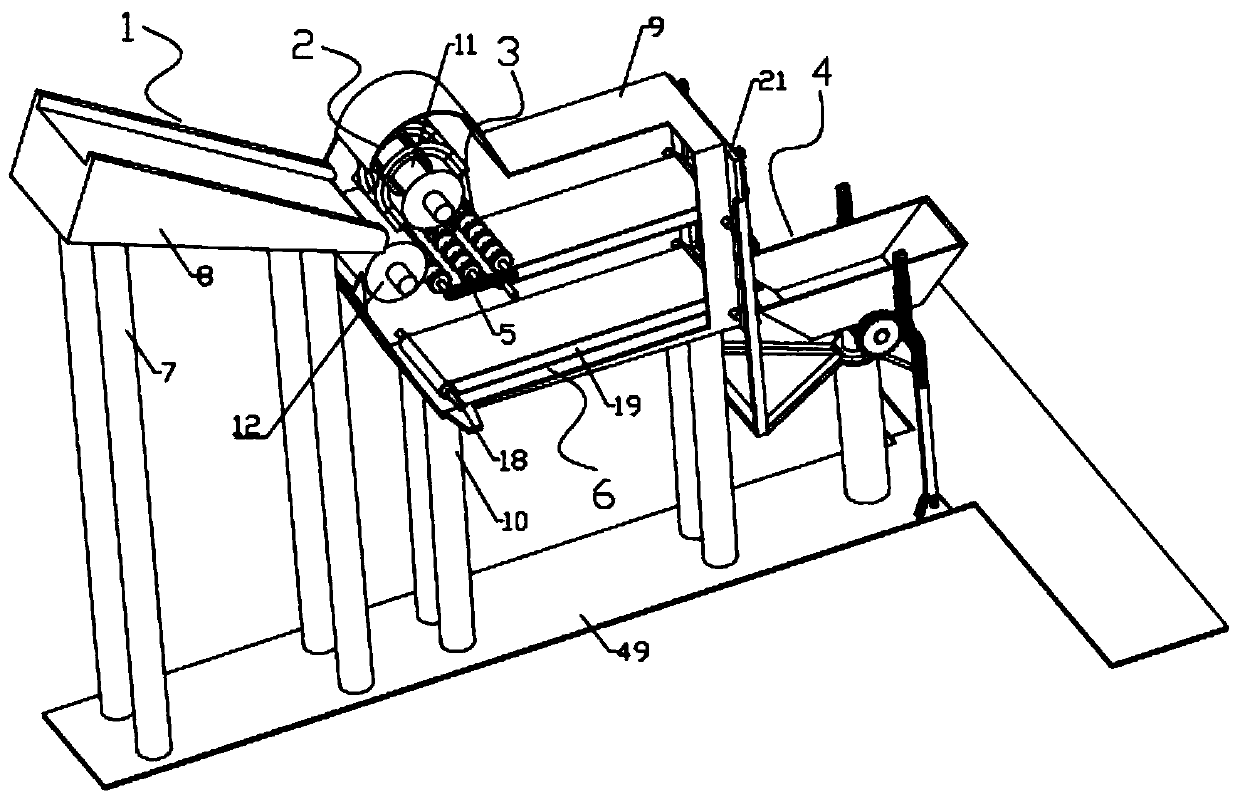

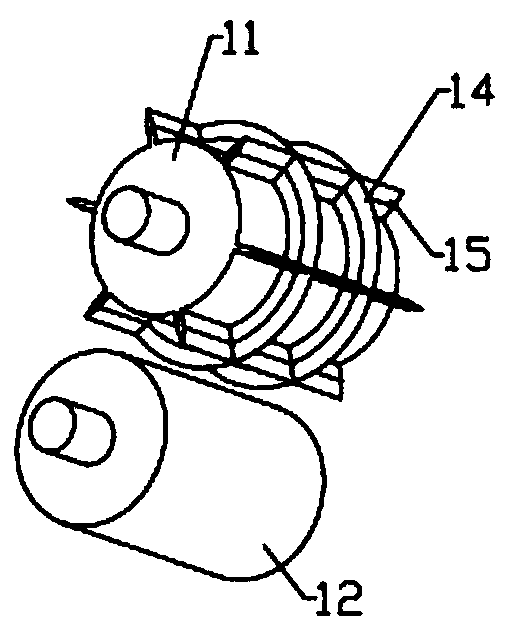

[0033] Such as Figure 1 to Figure 12 As shown, a food accurate quantitative packaging production line includes a material guide assembly 1, a cutting assembly 2, a feeding assembly 3, a quantitative weighing assembly 4, and a packaging assembly 50 arranged on a "T"-shaped bottom plate 49 from left to right. , the feeding assembly 3 includes a feeding roller 5 and a feeding system capable of transporting block food and crushed food separately, and the quantitative weighing assembly 4 can accurately weigh the block food and the crushed food according to the weight ratio of 9:1 Heavy and topple over to packing component 50 and pack blanking.

[0034] In this embodiment, the material guide assembly 1 includes four support columns 7 and a material gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com