Wood board surface shallow layer uniform carbonization device

A carbonization device and plank technology, applied in the direction of charcoal burning/combustion, etc., can solve the problems of affecting the carbonization operation of the plank and inconvenient turning over of the plank, and achieve the effects of improving uniform carbonization operation, convenient processing, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

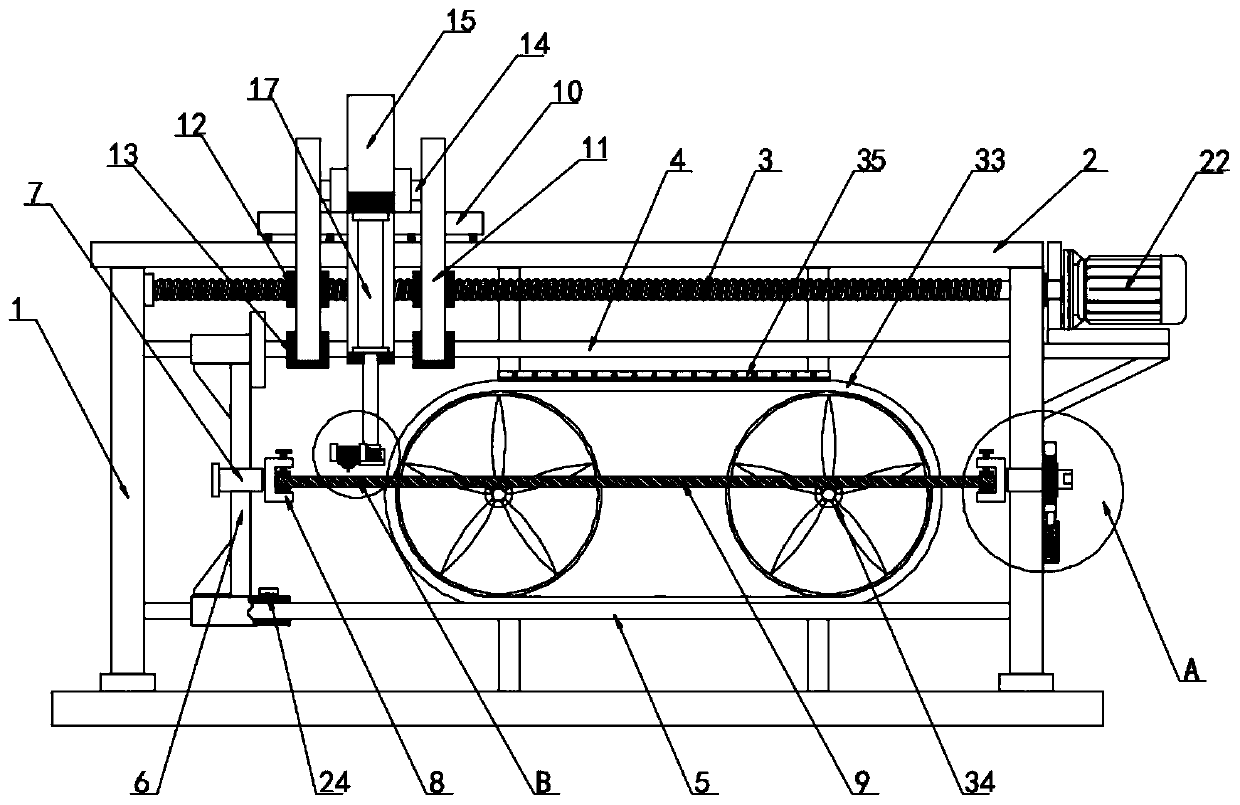

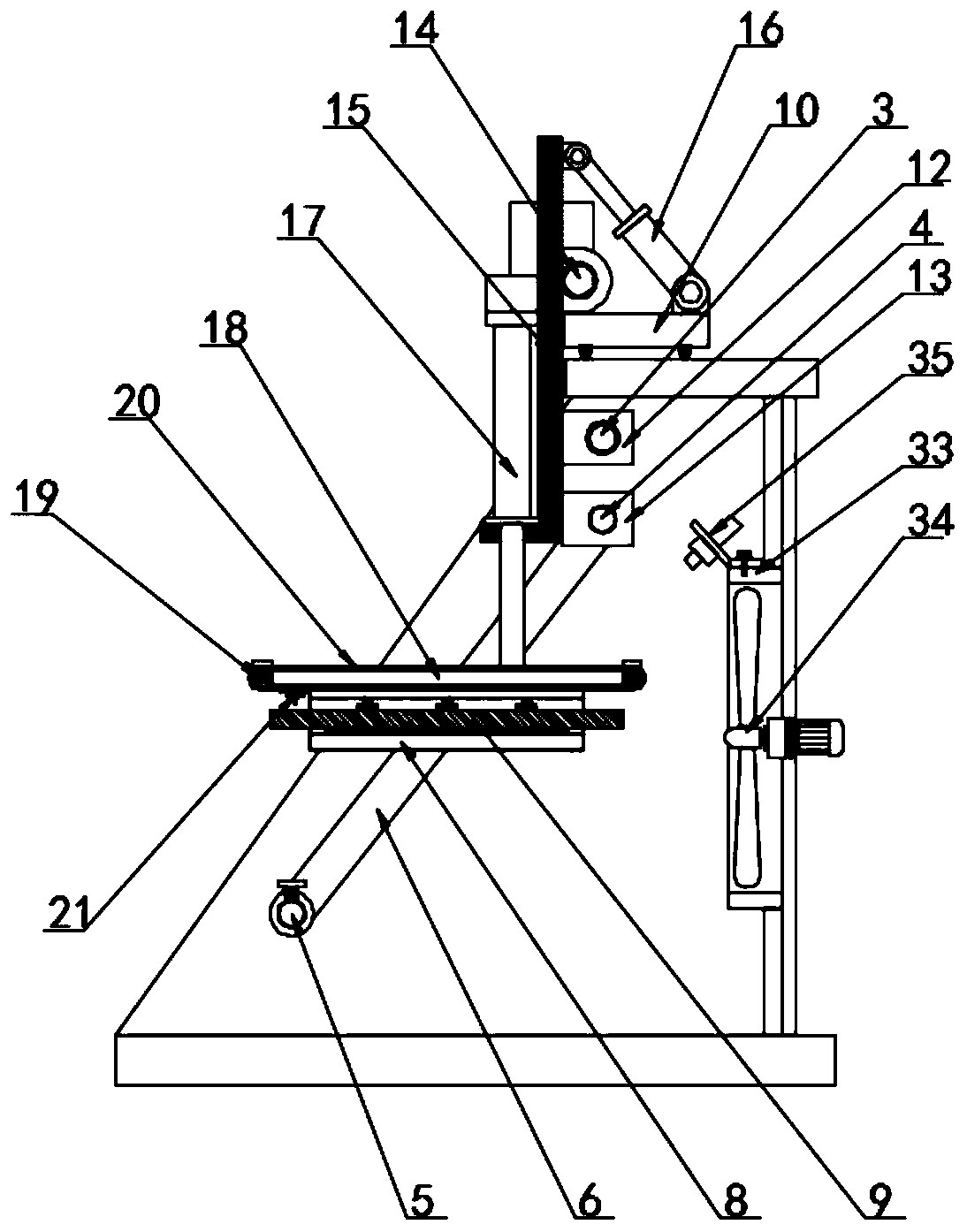

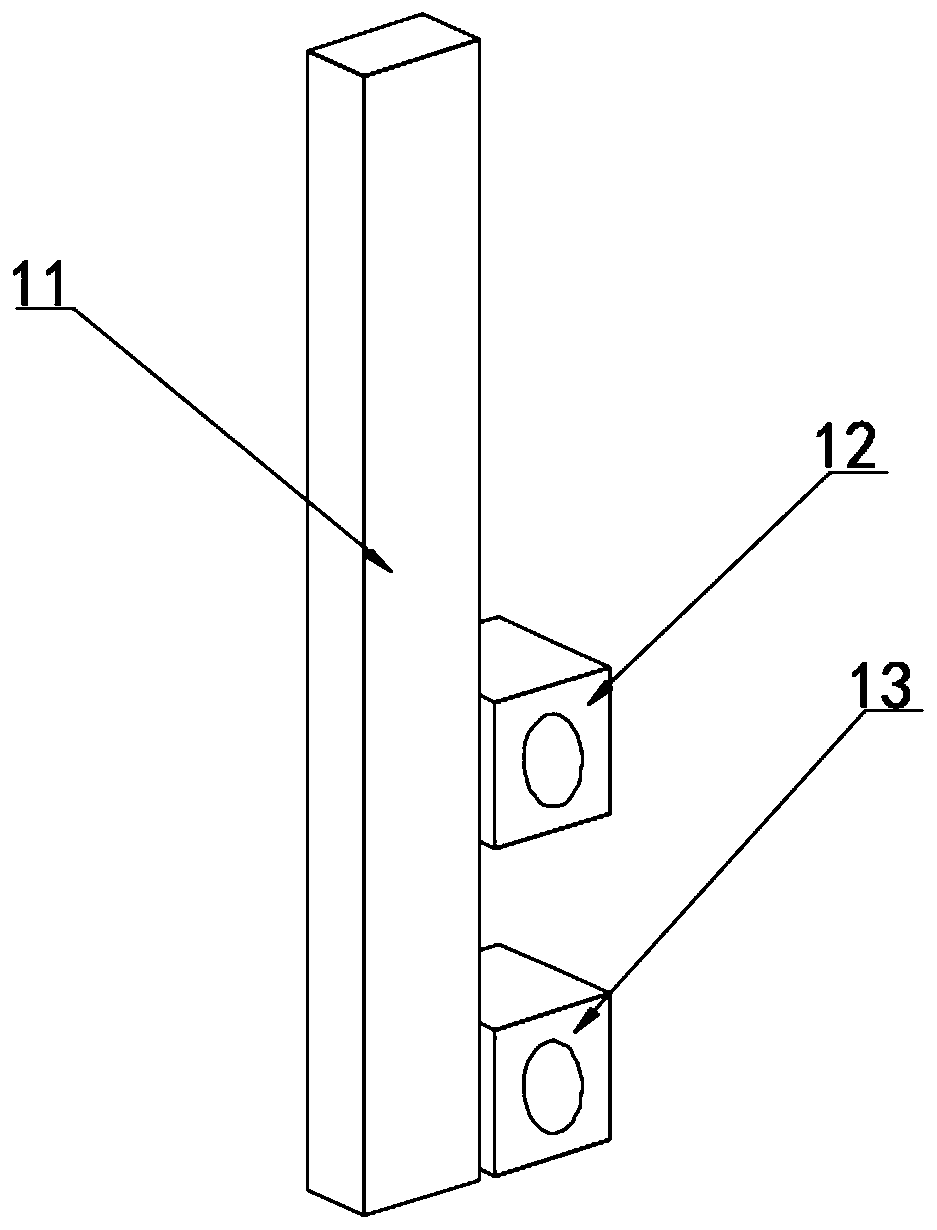

[0029] The present invention provides such as Figure 1-6 The shallow uniform carbonization device shown on the surface of a wooden board includes a frame 1, a fixed table 2, a threaded rod 3, an upper positioning slide bar 4, a lower positioning slide bar 5, a movable frame 6, a rotating shaft 7, and a clamping block 8 , movable platform 10, mounting frame 11, threaded block 12, positioning slider 13, fixed shaft 14, turret 15, turning cylinder 16, lifting cylinder 17, reciprocating frame 18, roller 19, conveyor belt 20, oxygen torch 21, drive Motor 22 and driving motor 23, the top of frame 1 is fixedly connected with fixed platform 2, and movable platform 10 is placed on fixed platform 2, and movable platform 10 front side left and right sides all are fixedly connected with mounting frame 11, and left and right sides mounting frame 11 A fixed shaft 14 is fixedly connected between the upper parts of the rear side, and the middle part of the fixed shaft 14 is rotatably connect...

Embodiment 2

[0032] Such as Figure 1-5 As shown in the shallow uniform carbonization device on the surface of a plank, the movable frame 6 is arranged obliquely, and the right side of the lower part of the movable frame 6 is provided with a fastening bolt 24, and the fastening bolt 24 cooperates with the lower positioning slide bar 5. By pushing The movable frame 6 moves on the upper positioning slide bar 4 and the lower positioning slide bar 5, which is convenient to adapt to planks 9 of different lengths, and facilitates the position fixing of the movable frame 6.

[0033] Further, there are grooves 25 in the middle of the inner sides of the clamping blocks 8 on the left and right sides, the inner bottom of the grooves 25 is fixedly connected with pads 26, and the top right side of the left clamping block 8 and the right clamping block 8 The left side of the top is provided with the compression bolt 27 that can compress the plank by thread, and the plank 9 is compressed by tightening th...

Embodiment 3

[0036] Such as Figure 1-7 In the shown shallow uniform carbonization device on the surface of a wooden board, a chuck 28 is fixedly connected to the right part of the right rotating shaft 7, and four slots 29 are evenly spaced on the side of the chuck 28 in the circumferential direction. The lower part of the right side is fixedly connected with a fixed block 30, and the fixed block 30 is slidably provided with a block 31 that cooperates with the draw-in groove 29. A spring 32 is connected between the bottom of the block 31 and the inner bottom of the fixed block 30, and the rotating shaft 7 When rotating, the rotating shaft 7 drives the chuck 28 to rotate, and whenever the chuck 28 rotates 90 degrees, the clamping block 31 and the slot 29 will be switched sequentially, so as to facilitate the flat state of the wooden board 9 during the flipping process. It is fixed with the vertical state, which is convenient for carbonization operation and cooling operation.

[0037] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com