Six-head automatic switching punching module

A technology of automatic switching and punching dies, applied in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of inability to quickly switch multiple ultrasonic punching units, low efficiency, and slow punching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

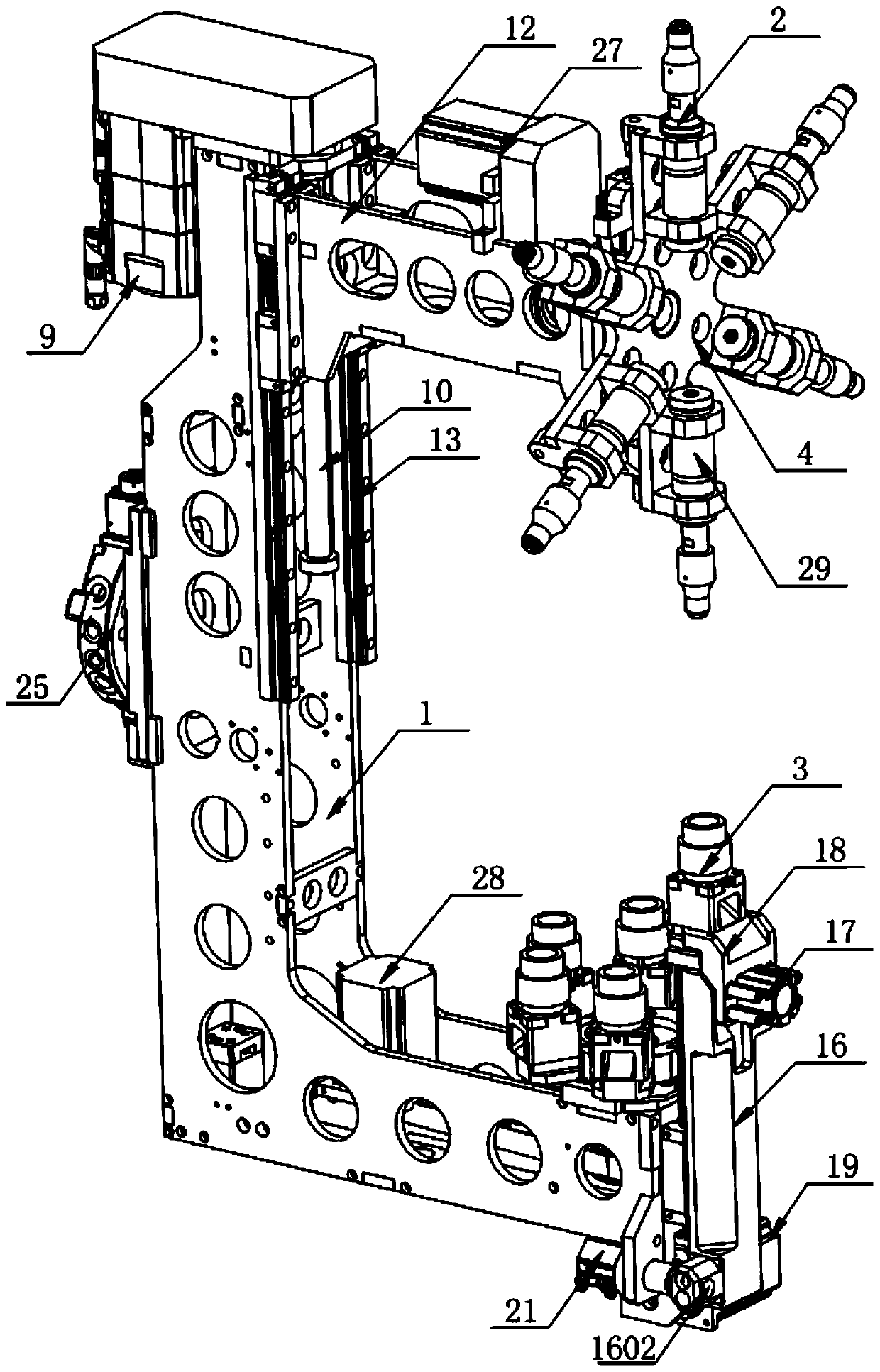

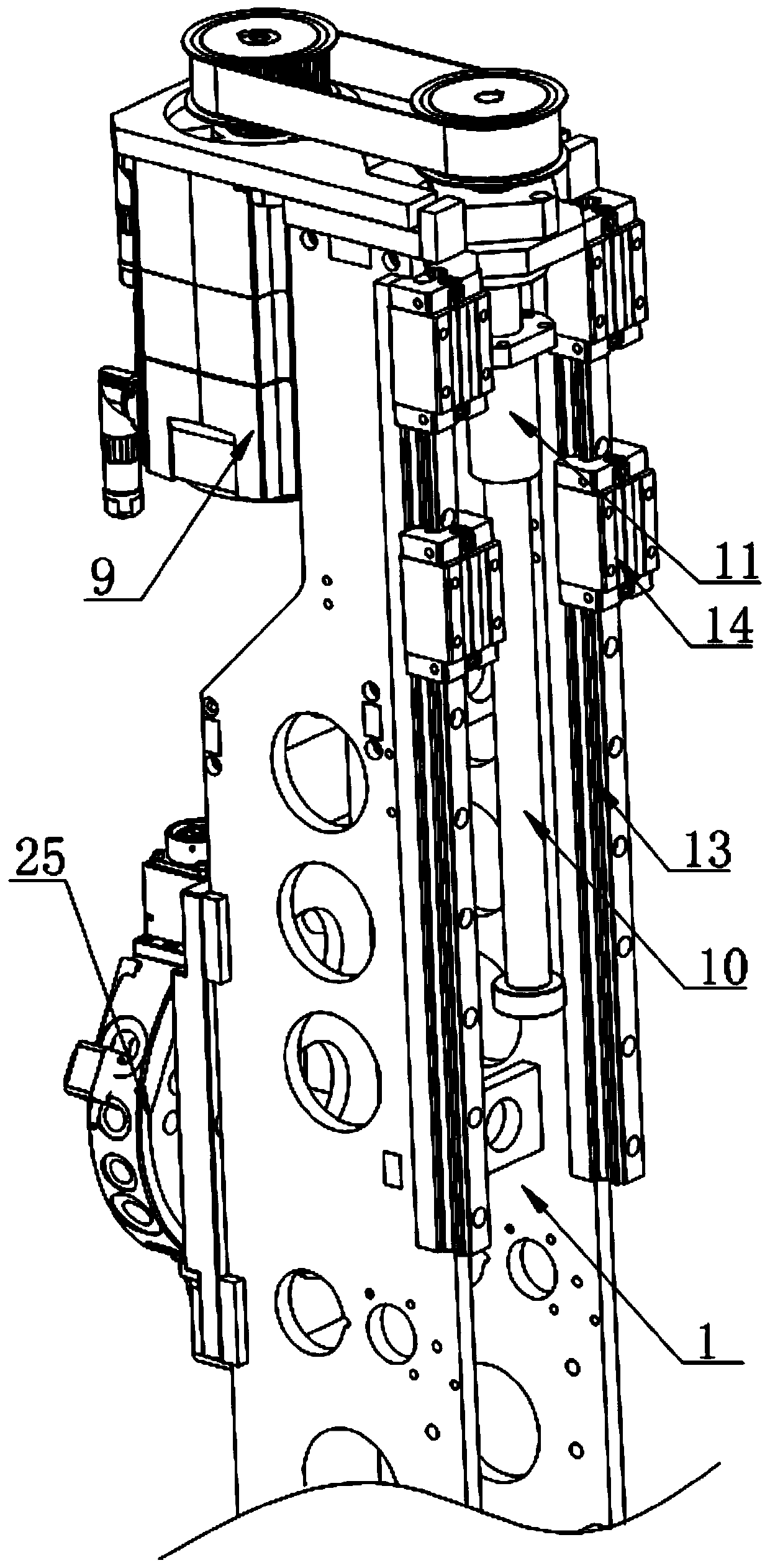

[0033] refer to Figure 1 to Figure 17 , the present invention provides a six-head automatic switch punching module, including: a bracket body 1, an upper punching knife mechanism and a lower punching knife mechanism, the bracket body 1 is L-shaped, and the bracket body 1 is designed for lightweight, the bracket body 1 The upper part is equipped with a lifting drive mechanism, the upper punching knife mechanism is slidably installed on the lifting drive mechanism through the punching knife disc support frame 12, the lower punching knife mechanism is installed at the bending end of the bracket body 1, and is opposite to the upper punching knife mechanism . The bracket body 1 is equipped with a quick-change disc 25 for connecting with an external manipulator. When punching, the manipulator docks with the quick-change disc 25 and drives the punching module to move to the punching position as a whole. The lower punching knife 3 and the upper punching knife Knife 2 is used in conj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com