Bulldozer crawler speed control method, device and bulldozer

A technology of crawler speed and control method, which can be applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Drop and other problems, to achieve the effect of slowing down the violent vibration of the whole vehicle and preventing rapid acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

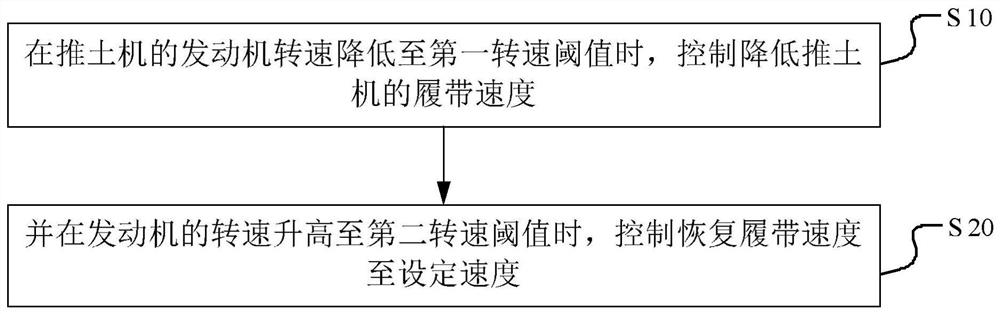

[0036] An embodiment of the present invention provides a method for controlling the speed of a bulldozer track, figure 1 It is a flow chart of a bulldozer crawler speed control method provided in Embodiment 1 of the present invention, refer to figure 1 , the control method includes:

[0037] S10. When the engine speed of the bulldozer is reduced to a first speed threshold, control to reduce the crawler speed of the bulldozer;

[0038] S20, and when the rotational speed of the engine rises to the second rotational speed threshold, control the recovery of the track speed to the set speed;

[0039] Wherein, the first rotational speed threshold is smaller than the second rotational speed threshold.

[0040] Specifically, during the actual operation of the bulldozer, when the load increases, the insufficient engine power will cause the engine speed to drop too fast or even turn off. In order to prevent this phenomenon, it is necessary to appropriately reduce the Track speed, com...

Embodiment 2

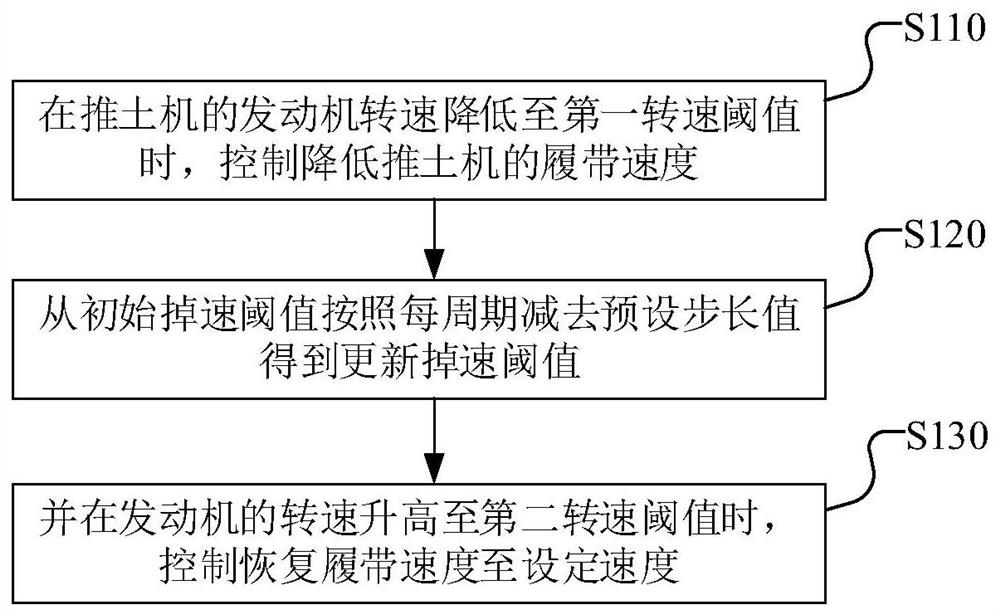

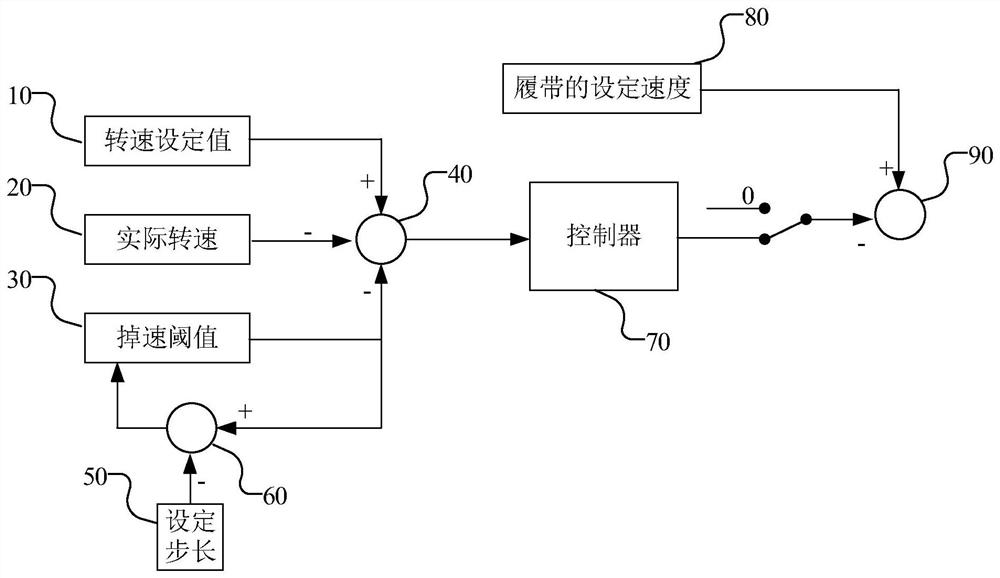

[0043] figure 2 It is a flow chart of a bulldozer crawler speed control method provided in Embodiment 2 of the present invention, refer to figure 2 , the bulldozer crawler speed control method includes:

[0044]S110. When the engine speed of the bulldozer decreases to a first speed threshold, control to reduce the speed of the crawler belt of the bulldozer;

[0045] S120. Obtain an updated speed drop threshold by subtracting a preset step value per cycle from the initial speed drop threshold;

[0046] S130, and when the rotational speed of the engine rises to the second rotational speed threshold, control to recover the track speed to the set speed.

[0047] Wherein, the first speed threshold is smaller than the second speed threshold; optionally, the first speed threshold is equal to the difference between the speed setting value and the initial speed drop threshold, and the second speed threshold is equal to the difference between the speed setting value and the updated ...

Embodiment 3

[0056] Figure 4 It is a flow chart of a bulldozer crawler speed control method provided in Embodiment 3 of the present invention, refer to Figure 4 , the bulldozer crawler speed control method includes:

[0057] S210. When the engine speed of the bulldozer is reduced to a first speed threshold, control the crawler speed of the bulldozer to be reduced;

[0058] S220. Obtain an updated speed-drop threshold by subtracting a preset step value from the initial speed-drop threshold in each cycle;

[0059] S230. Obtain the vehicle speed through the vehicle speed radar, and obtain the crawler speed through the crawler rotational speed sensor, and control the crawler speed according to the difference between the vehicle speed and the crawler speed.

[0060] Specifically, the vehicle speed is obtained in real time through the vehicle speed radar, and the track speed is obtained in real time through the track speed sensor, and whether the track speed is within the set range is judged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com