Lifting hanger for pre-branched cable and method for lifting pre-branched cable

A technology of pre-branching and cables, which is applied in the field of lifting hangers for pre-branching cables and lifting of pre-branching cables, and can solve the problems of low reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

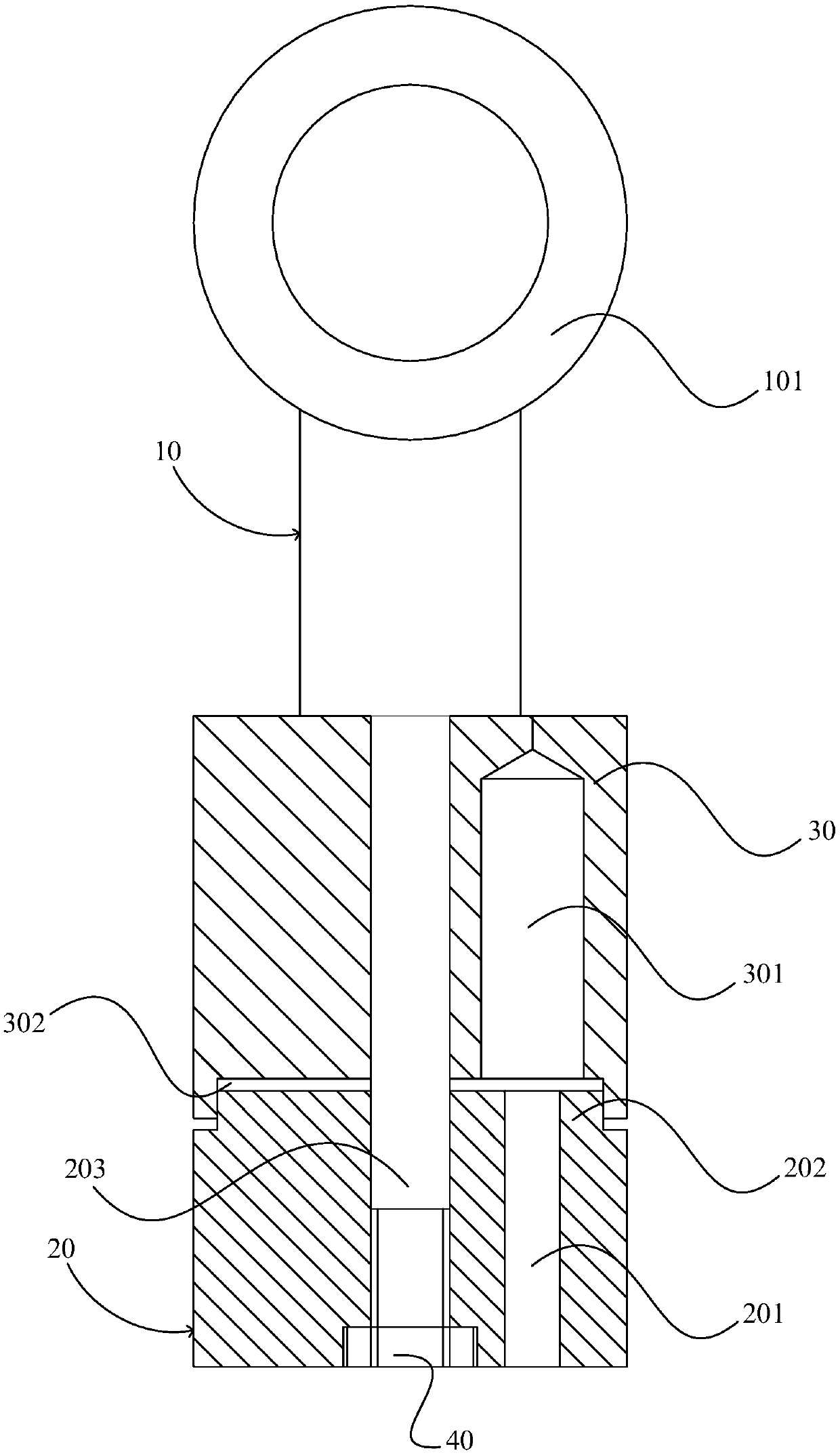

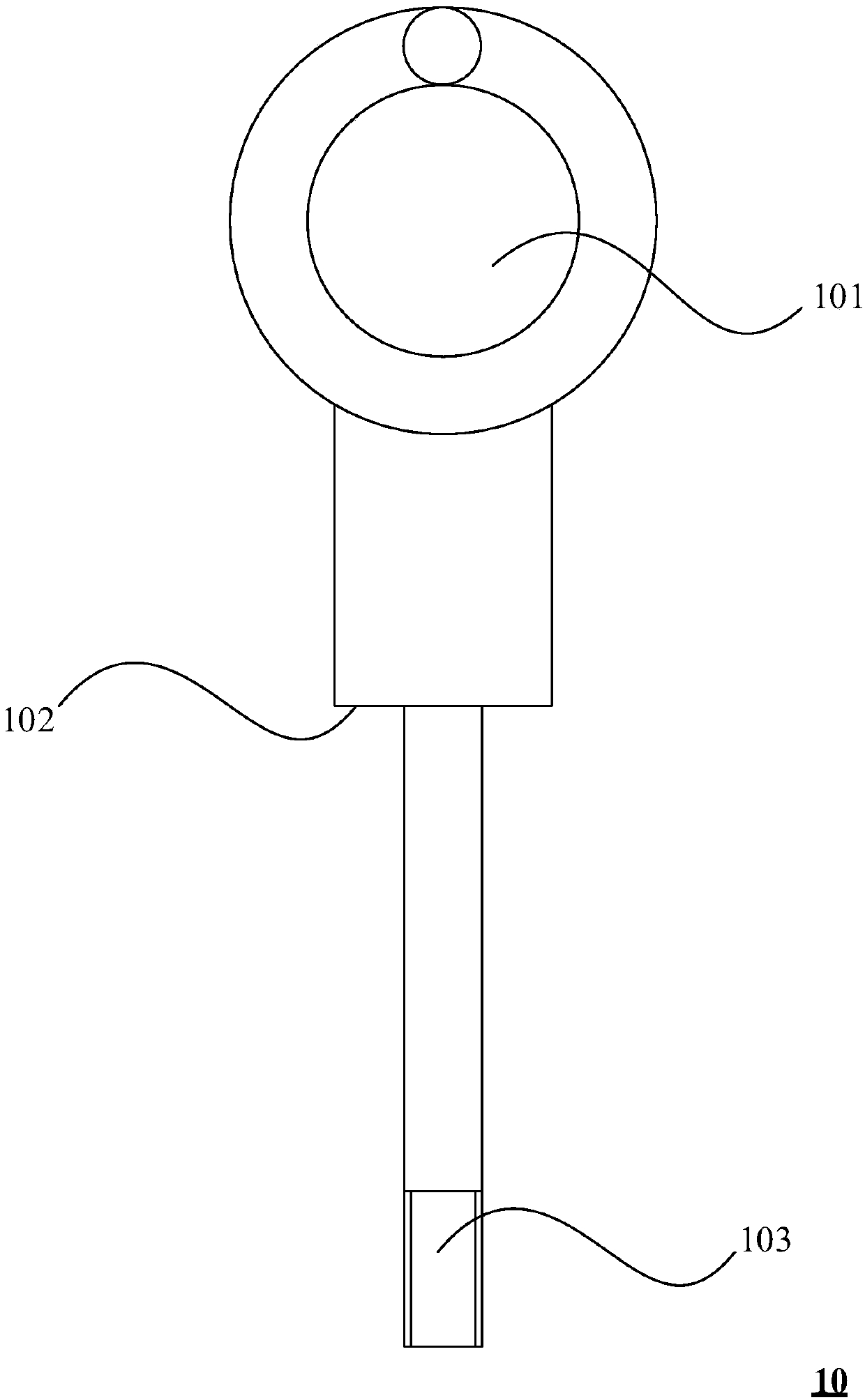

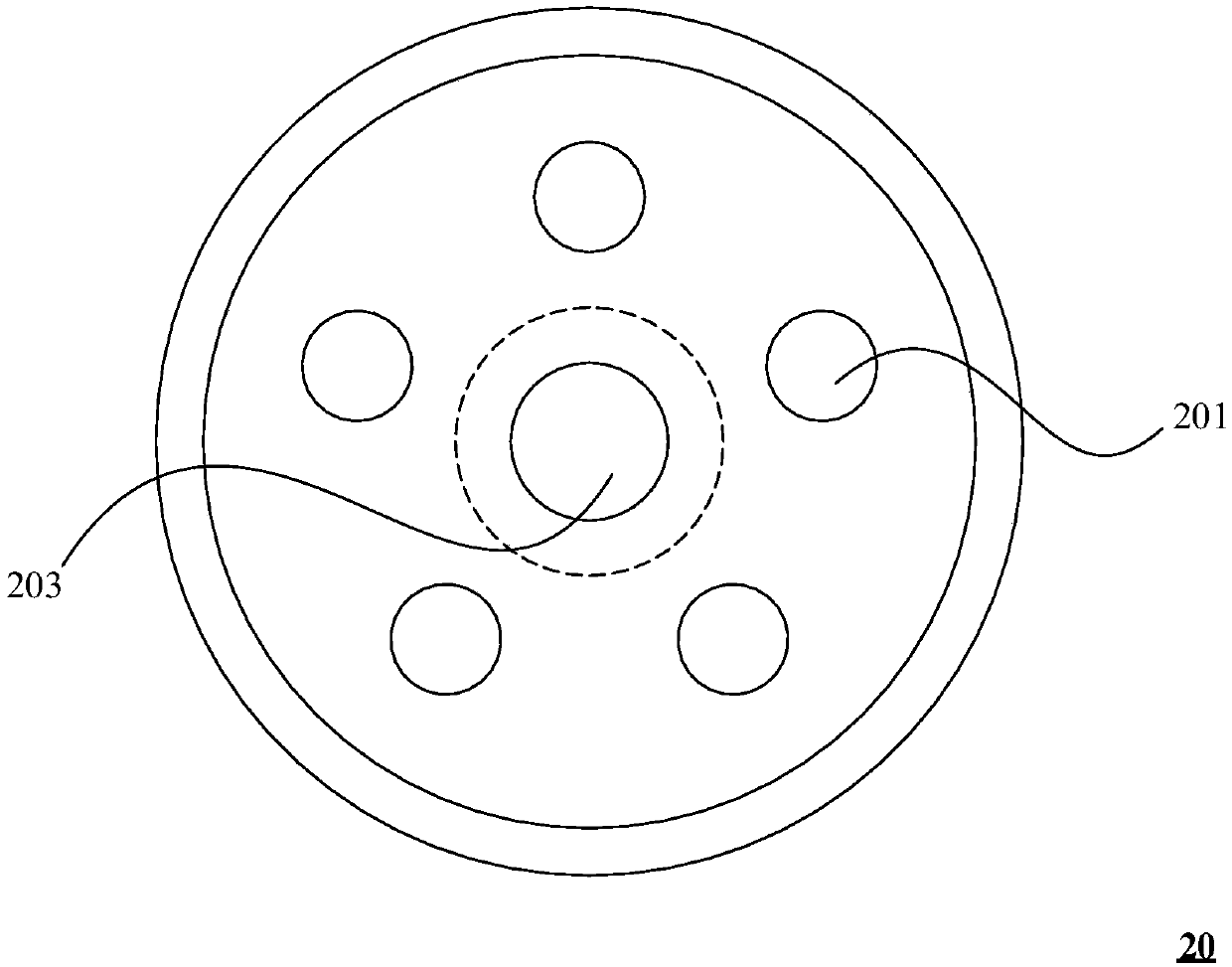

[0062]This embodiment discloses a lifting hanger for a pre-branched cable, the pre-branched cable has multiple wire cores, refer to Figure 1-4 It should be understood that the lifting hanger includes a boom 10 , a bearing block 20 and a plurality of limiting parts (not shown in the figure). The boom 10 has a head end and a tail end along the length direction, and the head end of the boom 10 has a lifting ear 101 . The load-bearing block 20 is sleeved on the tail end of the suspender 10, and the load-bearing block 20 is provided with a plurality of first accommodating holes 201 ( image 3 5 first accommodating holes 201 are shown in , and the first accommodating holes 201 extend along the length direction of the boom 10 . A plurality of stoppers abut against one end of the load-bearing block 20 toward the head end of the boom 10, and the plurality of stoppers are arranged in one-to-one correspondence with the plurality of first accommodating holes 201. The second accommodati...

Embodiment 2

[0073] This embodiment discloses a hoisting method for pre-branched cables. The hoisting method utilizes the hoisting hanger in Embodiment 1. Refer to Figure 5 It is to be understood that the hoisting method comprises the following steps:

[0074] Step 100, stripping off the end of the pre-branched cable, so that multiple wire cores are exposed to a preset length;

[0075] Step 200, make a plurality of wire cores pass through the load-bearing block through a plurality of first accommodating holes and expose to the load-bearing block;

[0076] Step 300, sleeve the plurality of washers on the plurality of wire cores respectively, so that the plurality of washers fit on the bearing block;

[0077] Step 400, connecting multiple limiters to multiple wire cores respectively;

[0078] Step 500, sleeve the gland on a plurality of position-limiting parts through a plurality of second accommodating holes, and connect the gland to the load-bearing block;

[0079] Step 600 , make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com