Sampling device for soil detection

A sampling device and soil detection technology, applied in the direction of sampling devices, etc., can solve the problems of affecting sampling work, soil sampling at different depths, and easy movement of sampling devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

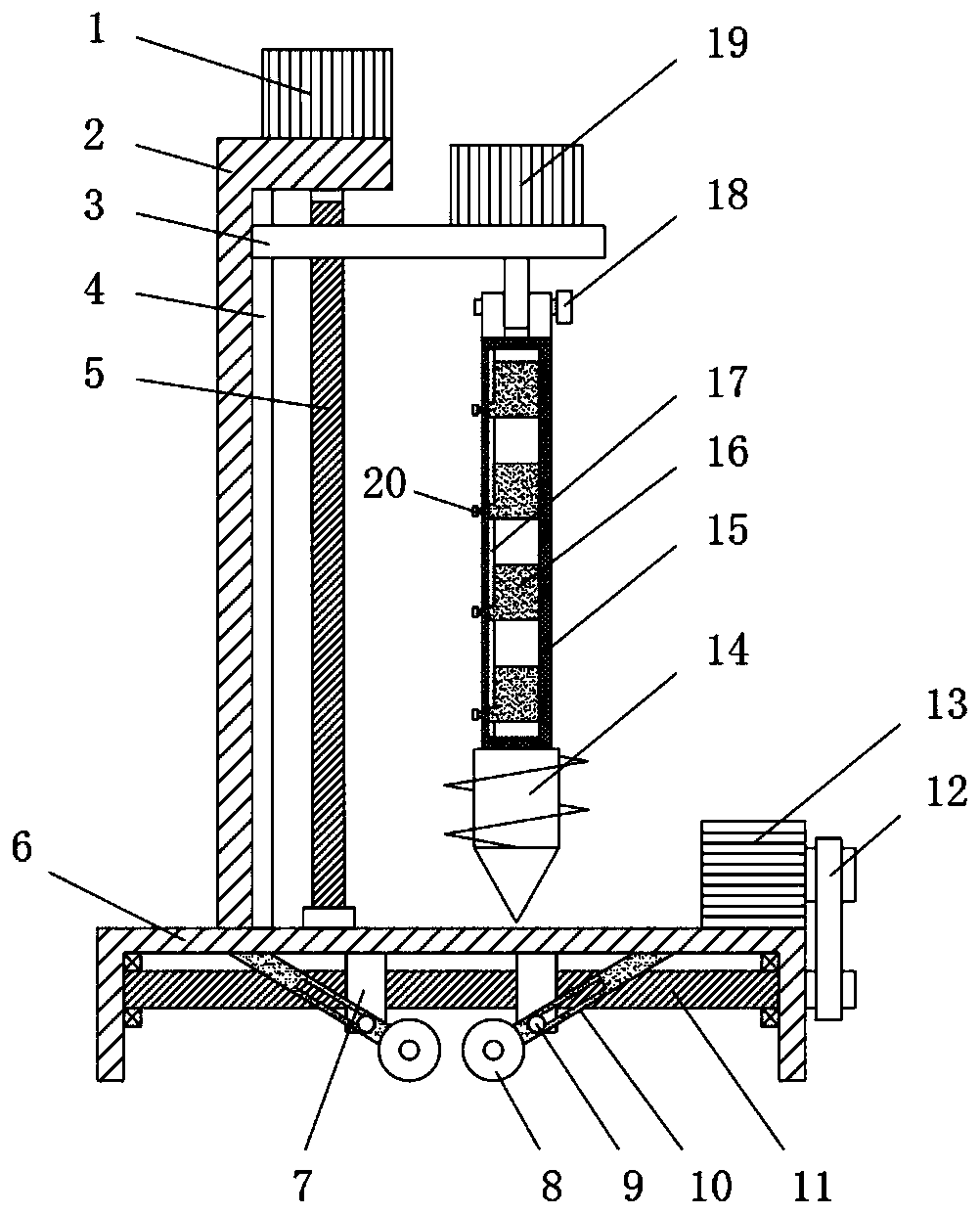

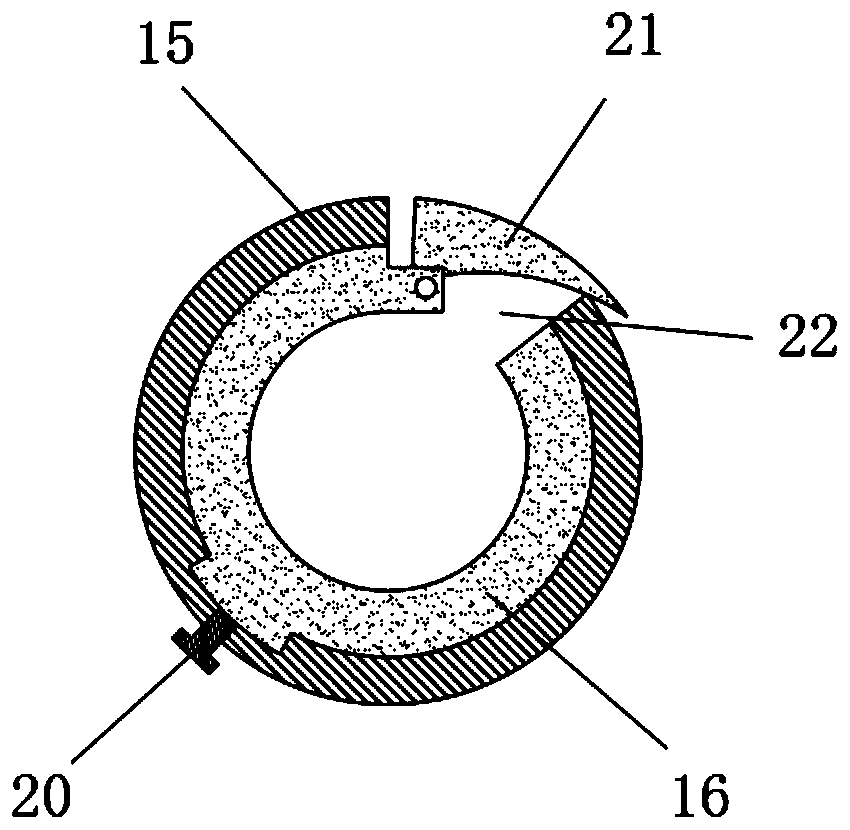

[0023] see Figure 1~4 , in an embodiment of the present invention, a sampling device for soil detection, comprising a base 6 and a soil sampling assembly arranged on the base 6 and a lifting assembly for controlling the lifting of the soil sampling assembly, the soil sampling assembly includes a third drive motor 19 and sleeve 15, the third drive motor 19 is fixedly installed on the lifting assembly, the top of the sleeve 15 is fixedly connected with the output end of the third drive motor 19, the bottom of the sleeve 15 is fixedly equipped with a drill bit 14, the sleeve The inner wall of 15 is provided with a second chute 17, and a plurality of sampling boxes 16 are slided in the second chute 17, and the sampling boxes 16 are fixed between the second bolt 20 and the sleeve 15, and the sleeve 15 And sampling box 16 is all provided with opening 22, and the opening 22 place of sampling box 16 is rotated and is provided with scraper block 21, and described base 6 is also provid...

Embodiment 2

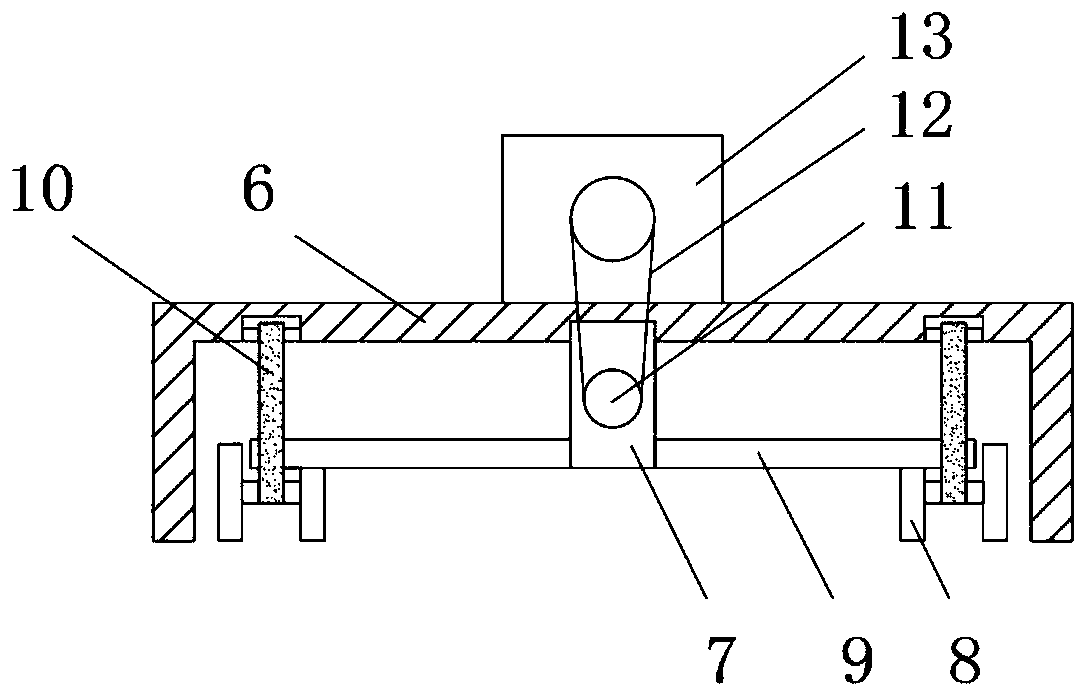

[0030]This embodiment is a further improvement on the basis of embodiment 1. Compared with embodiment 1, the main difference is that: the moving assembly includes a second screw 11 and a swing rod 10, and the second screw 11 is rotatably arranged on the base 6, on the second screw 11, there are two sliders 7 symmetrically sleeved left and right, the two sliders 7 are threadedly matched with the second screw 11 and the threads on the two sliders 7 are reversed, The top of slide block 7 slides and is set on base 6, and the bottom both sides of slide block 7 is fixedly installed with fixed rod 9, and one end of described swing rod 10 is rotatably arranged on base 6, and the other end of swing rod 10 is rotatably provided with The wheel 8 is provided with a bar-shaped groove on the swing rod 10, and the fixed rod 9 is slidingly clamped in the bar-shaped groove of the swing rod 10. The second drive motor 13 is fixedly installed on the base 6, and the second drive motor 13 Through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com