Automatic welding positioning device for automobile drive axle housing

A drive axle housing, automatic welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low production efficiency, low positioning accuracy, high labor cost, improve production efficiency, reduce labor costs, labor costs low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0107] Embodiment one:

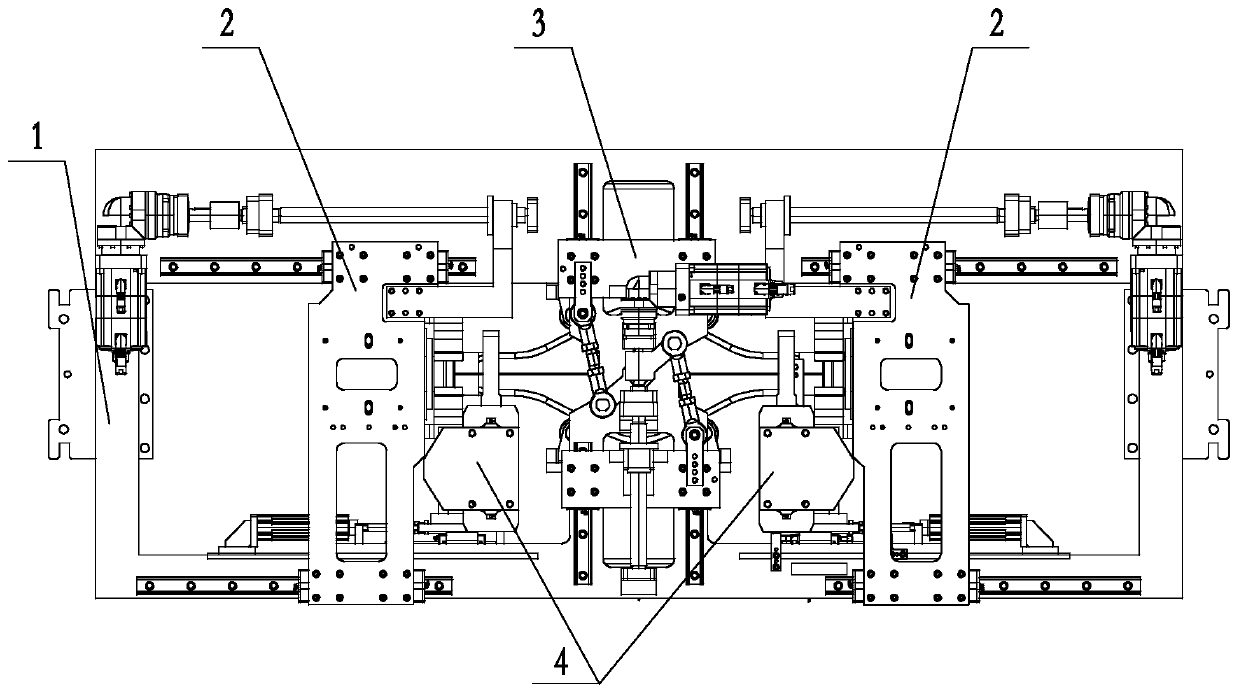

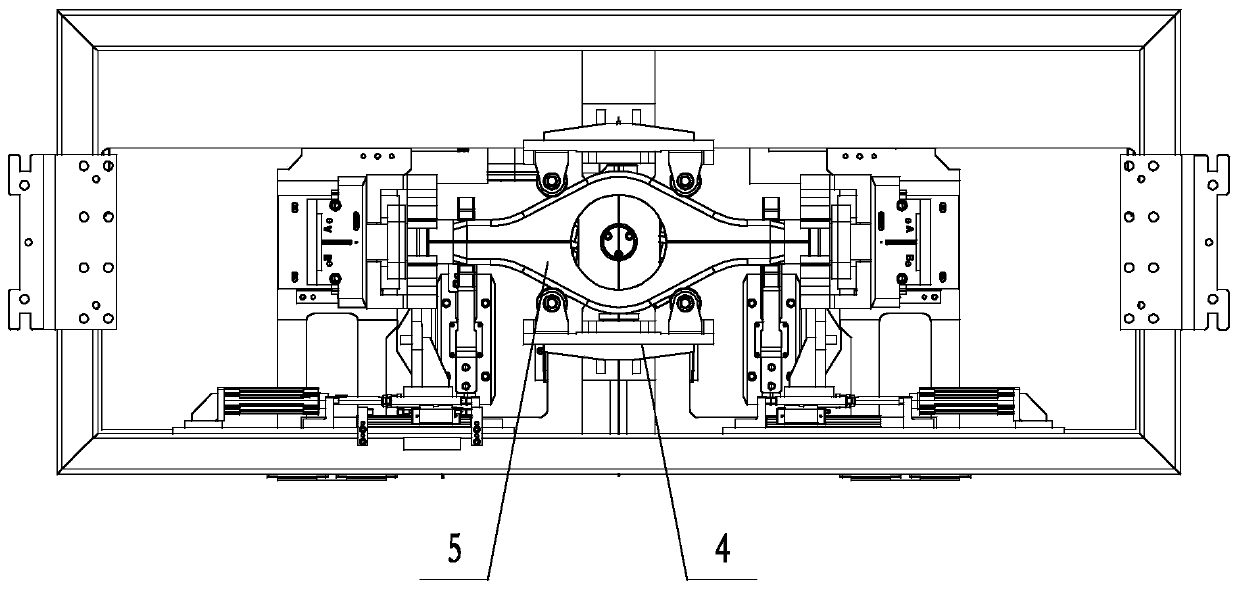

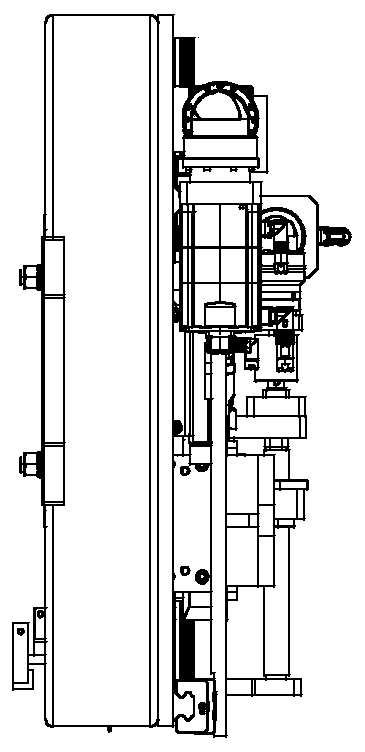

[0108] An automatic welding positioning device for an automobile drive axle housing, comprising a base device 1, a longitudinal positioning device 2, an automatic centering device 3, and an auxiliary clamping device 4, and the longitudinal positioning device 2 and the auxiliary clamping device 4 have two sets respectively , are installed on the left and right sides of the base device 1 respectively;

[0109] The base device 1 includes a base plate support 11 for carrying all parts of the entire device, a positioner joint 12 for quick connection with the positioner, the base plate support 11 is a square steel plate, and the frame is surrounded by steel plates; The positioner joint 12 is a steel plate with a concave groove 121 and a U-shaped interface 122 .

[0110] The longitudinal positioning device 2 includes a screw drive mechanism 21 and an end axis centering mechanism 22, wherein:

[0111] The screw drive mechanism 21 includes a servo motor I211,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com