Filter element integration device

An integrated device and filter element technology, applied in ultrafiltration, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems affecting normal work, ultrafiltration membrane knotting, rod imbalance, etc. The effect of slipping and preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

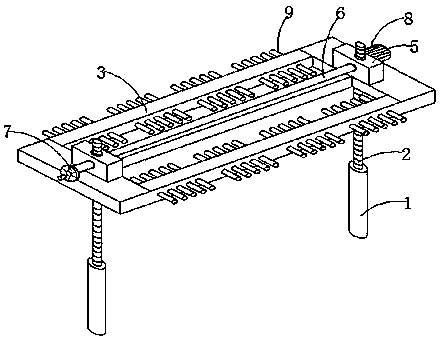

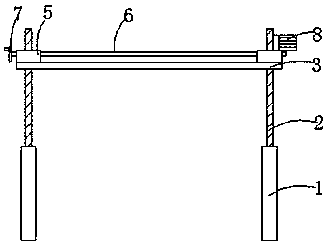

[0024] Such as Figure 1-4 As shown, a filter element integration device includes two support bottom rods 1 and a threaded rod 2 located at the upper end of the support bottom rod 1, the lower end of the support bottom rod 1 is fixedly installed on the ground, and the threaded rod 2 is vertically fixed and installed on the support bottom On the upper end of the rod 1, a bracket 3 is movable between the two threaded rods 2. The left and right ends of the bracket 3 are provided with sliding grooves 4 up and down. The threaded rod 2 and the sliding groove 4 are in clearance fit. The gear assembly 5, the steering gear assembly 5 includes a protective shell 501, the inner rotation of the protective shell 501 is equipped with a steering gear 502, the upper and lower ends of the protective shell 501 are provided with a first circular hole 503, and the left and right ends are provided with a second circular hole 504 , the threaded rod 2 passes through the two first round holes 503, an...

Embodiment 2

[0027] Such as Figure 1-5 As shown, a filter element integration device includes two support bottom rods 1 and a threaded rod 2 located at the upper end of the support bottom rod 1, the lower end of the support bottom rod 1 is fixedly installed on the ground, and the threaded rod 2 is vertically fixed and installed on the support bottom On the upper end of the rod 1, a bracket 3 is movable between the two threaded rods 2. The left and right ends of the bracket 3 are provided with sliding grooves 4 up and down. The threaded rod 2 and the sliding groove 4 are in clearance fit. The gear assembly 5, the steering gear assembly 5 includes a protective shell 501, the inner rotation of the protective shell 501 is equipped with a steering gear 502, the upper and lower ends of the protective shell 501 are provided with a first circular hole 503, and the left and right ends are provided with a second circular hole 504 , the threaded rod 2 passes through the two first round holes 503, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com