A high-strength automobile intermediate shaft

An intermediate shaft and high-strength technology, which is applied to the steering control and steering column installed on the car, can solve the problem of insufficient tightness of the connection of the external main shaft, loose connection of the reinforced structure, easy deformation and damage of the shaft, etc. problem, to achieve the effect of good adhesion, stable structure, easy replacement and adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

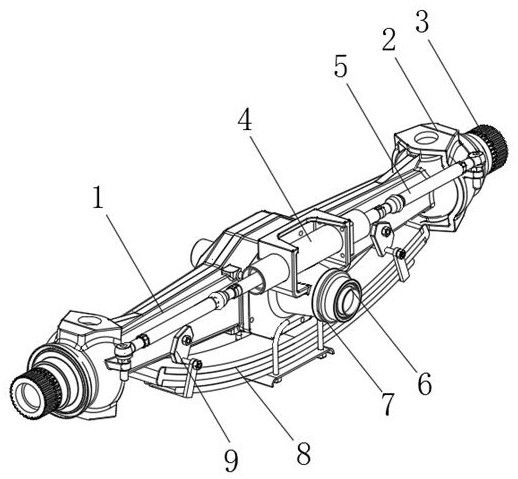

[0029] See Figure 1-5 A high-strength vehicle intermediate shaft, including the intermediate shaft body 1, two ends of the intermediate shaft body 1 provided with a connecting head 3, and the connection head 3 is provided with a movable structure 2, the intermediate shaft body 1. The front end outer surface is provided with a cylinder 4, and both the telescopic ends of the cylinder 4 are connected to a connecting structure 5, and the cylinder 4 and the movable structure 2 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com