Checking fixture for automobile engine left/right rear suspension

A technology of automobile engine and rear suspension, applied in the direction of using mechanical devices, mechanical measuring devices, mechanical clearance measurement, etc., can solve the problems of uncontrolled installation quality of parts, low efficiency of parts acceptance and inaccurate detection, etc. Achieve the effect of strong practicability, saving man-hours and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims:

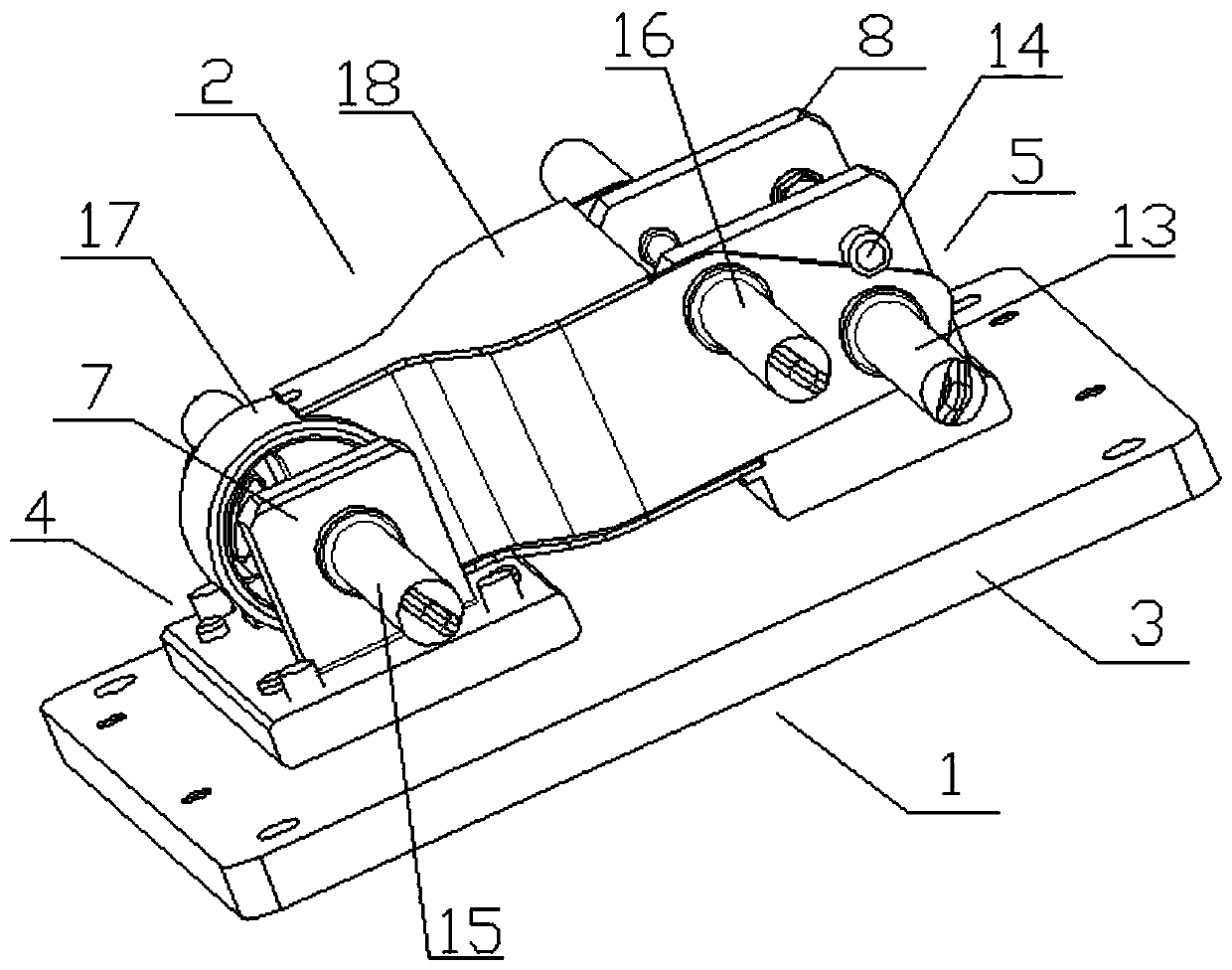

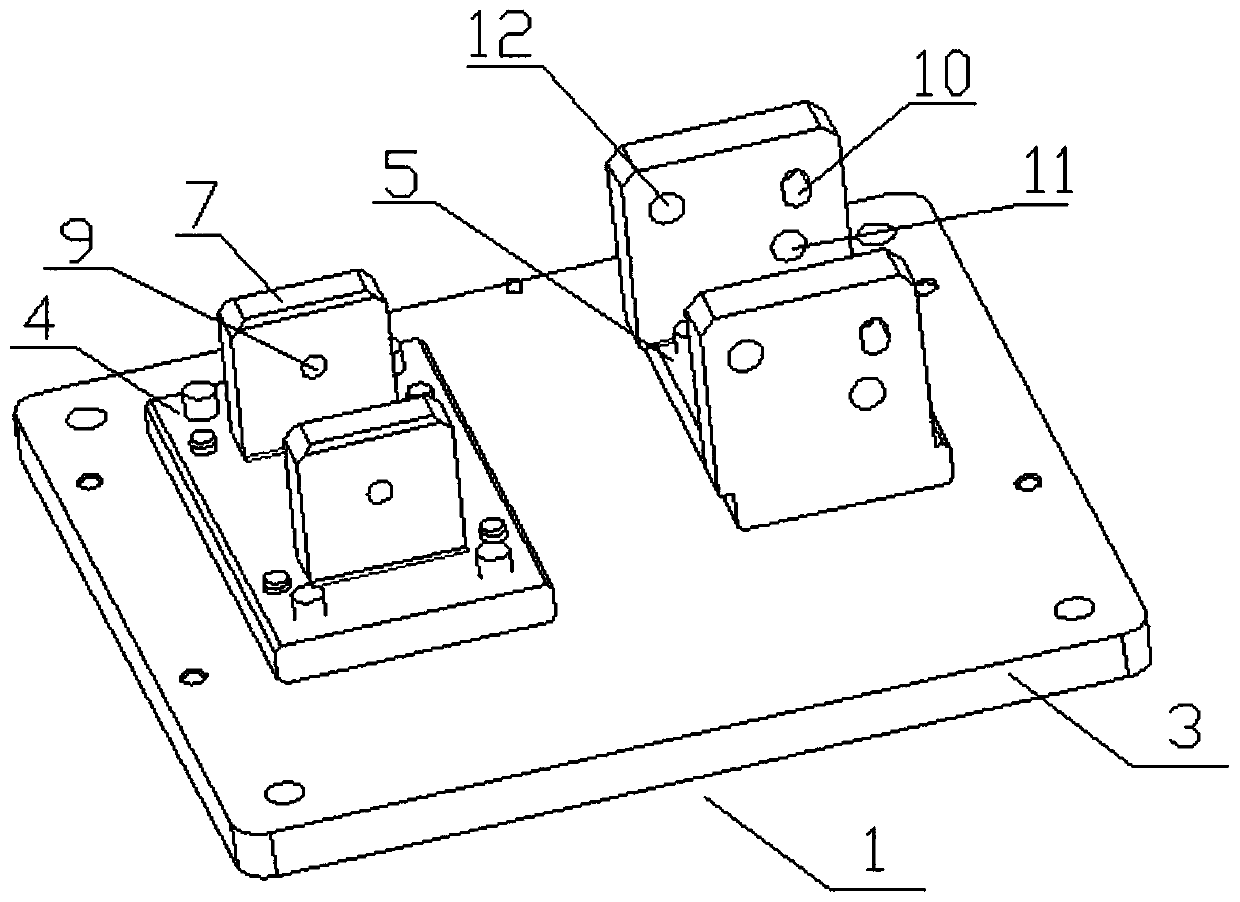

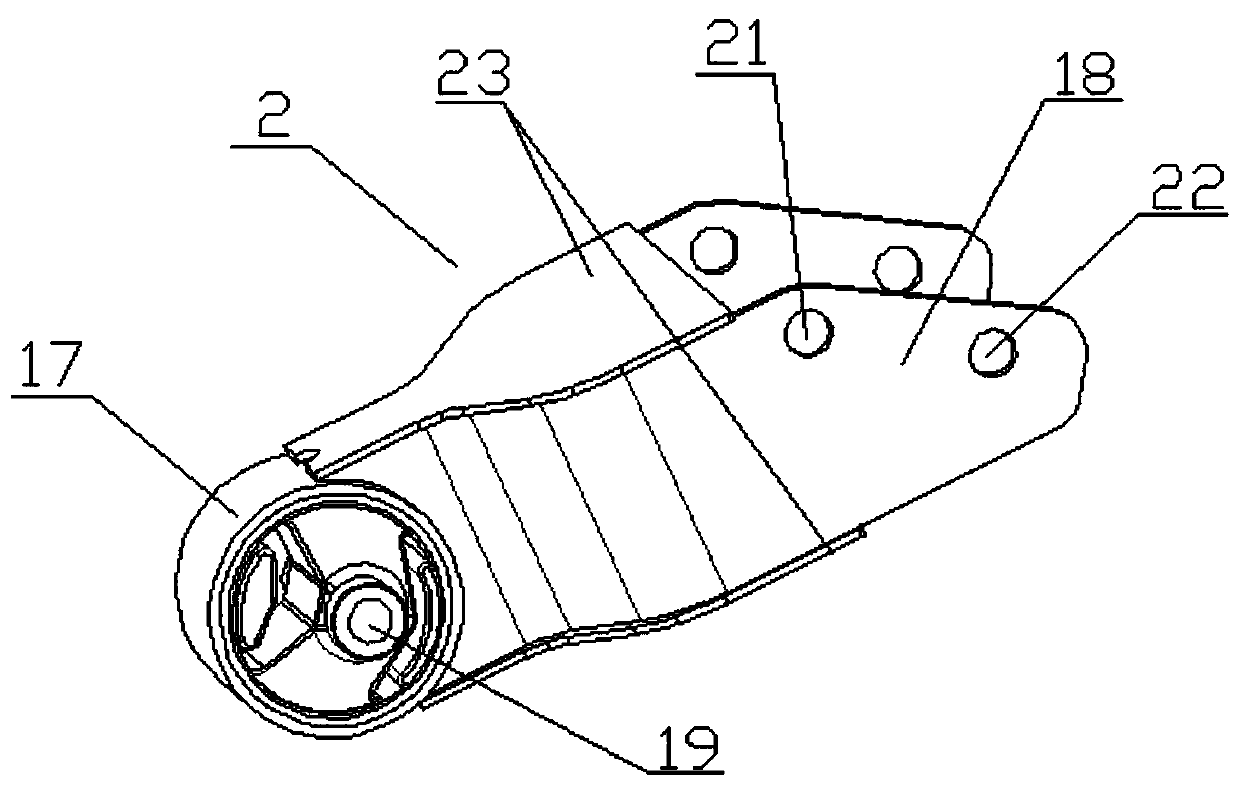

[0020] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a checker for the left / right rear suspension of an automobile engine, including a checker 1, a suspension test piece 2 is installed on the checker 1, and the checker 1 includes a base 3 and is fixed on the base 3 The front seat 4, the rear seat 5, and the test tool, each front seat 4 is provided with a positioning plate 7, and the rear seat 5 is provided with two mutually aligned detection plates 8.

[0021] Please refer to figure 1 as well as figure 2 , each positioning plate 7 is provided with a head positioning hole 9, and each detection plate 8 is provided with a limit pin hole 10, a positioning pin hole 11, and a check pin hole 12. The checker includes two po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com