Filter tank

A filter tank and filter screen technology, applied in the field of filter tanks, can solve problems such as affecting production efficiency, consuming manpower, and easily blocking the filter screen, reducing labor costs, reducing the number of times of replacing the filter screen, and avoiding work stoppage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as figure 1 as shown, figure 1 It is the structural diagram of filter tank in the embodiment. The filter tank of the present invention includes a tank body 1 and a filter core 2, the filter core 2 is located in the tank body 1, and the filter core 2 is arranged between the discharge end 11 and the discharge end 12 of the tank body 1; the filter core 2 comprises a filter screen 21 And the solid-liquid separator 22, the filter screen 21 is wrapped in the solid-liquid separator 22. Wherein, the waste water enters from the discharge end 11 of the tank body 1 , undergoes solid-liquid separation through the filter screen 21 and the solid-liquid separator 22 , and finally discharges the solid and liquid from the discharge end 12 of the tank body 1 .

[0025] The discharge end 12 of the tank body 1 includes a solid discharge port 121 and a liquid discharge port 122, the solid discharge port 121 communicates with the area where the solid-liquid separator 22 is located, an...

Embodiment 2

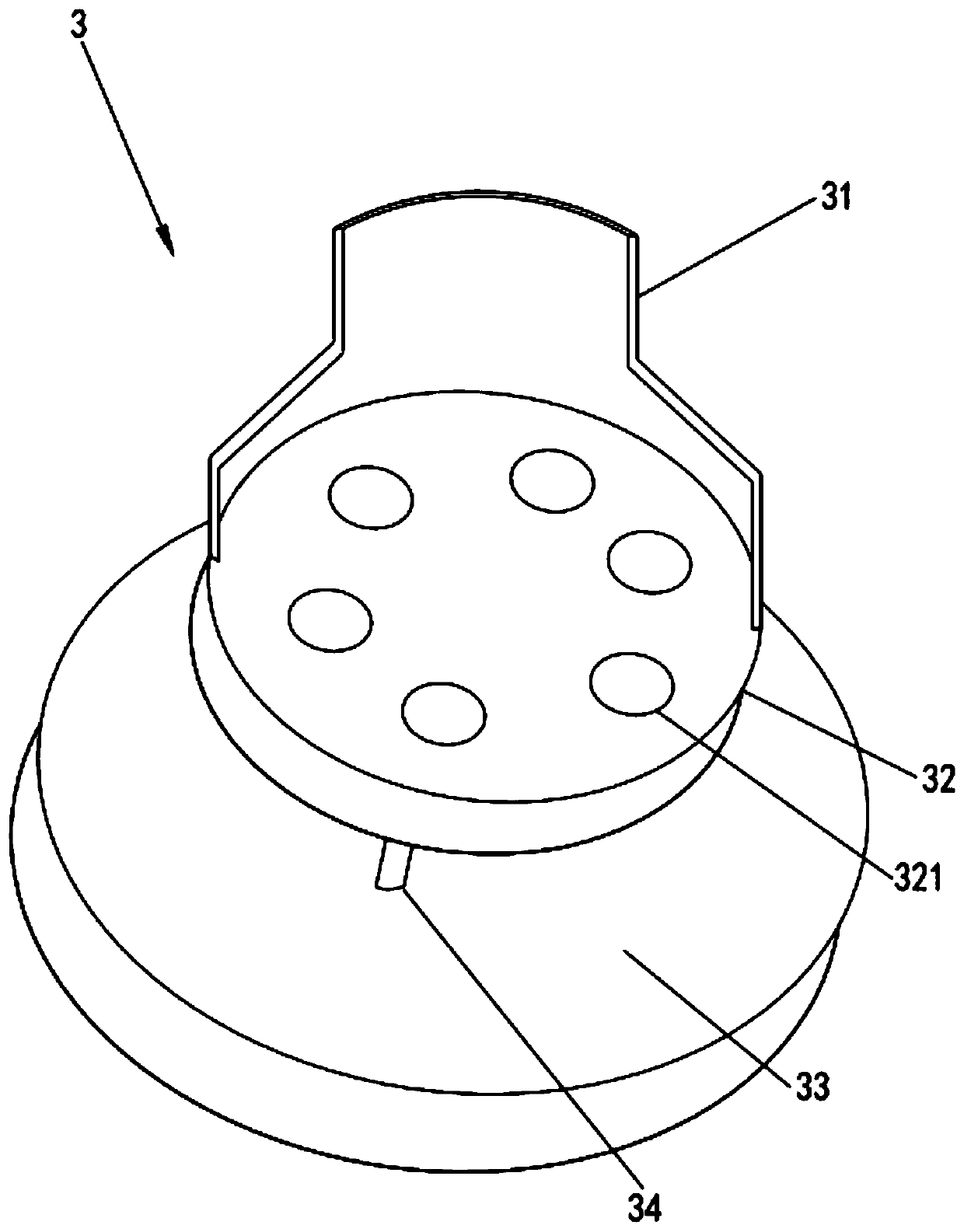

[0037] The difference between this embodiment and Embodiment 1 is that, if image 3 as shown, image 3 It is a structural diagram of the water separator 3 in the embodiment. The filter tank also includes a water separator 3 located between the discharge end 11 and the separation disc body 221 . The water separator 3 includes a water diversion cover 31, a first water diversion plate 32, a second water diversion plate 33 and a water diversion connector 34. The water diversion cover 31 is connected to the discharge end 11, and the water diversion cover 31 is covered with a On the first water distribution board 32 , the second water distribution board 33 is connected to the first water distribution board 32 through the water distribution connection part 34 . Specifically, the water separating cover 31 is funnel-shaped.

[0038] Preferably, the first water diversion plate 32 is provided with a plurality of water diversion holes 321, and the plurality of water diversion holes 321...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com