Cracking gasifier capable of uniformly mixing materials, dropping slag or discharging slag

A pyrolysis gasification and slag-dropping technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of large floor space, high investment cost, slag-dropping and slag-discharging mechanism furnace pan blockage, etc. Cost-effective, simple structure, and the effect of saving structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is only for disclosing the present invention to enable those skilled in the art to practice the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications. The basic principles of the invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and others without departing from the spirit and scope of the invention.

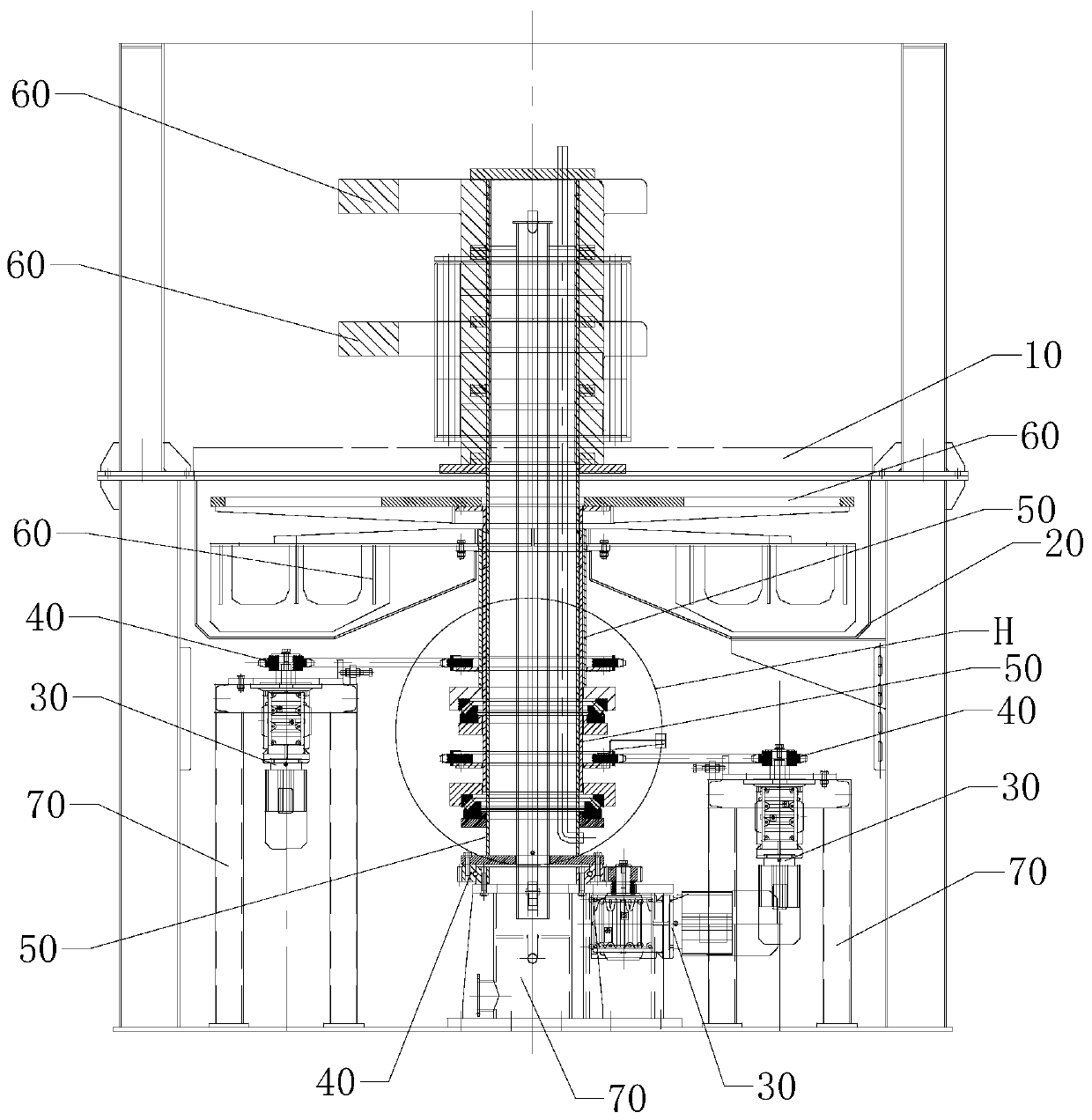

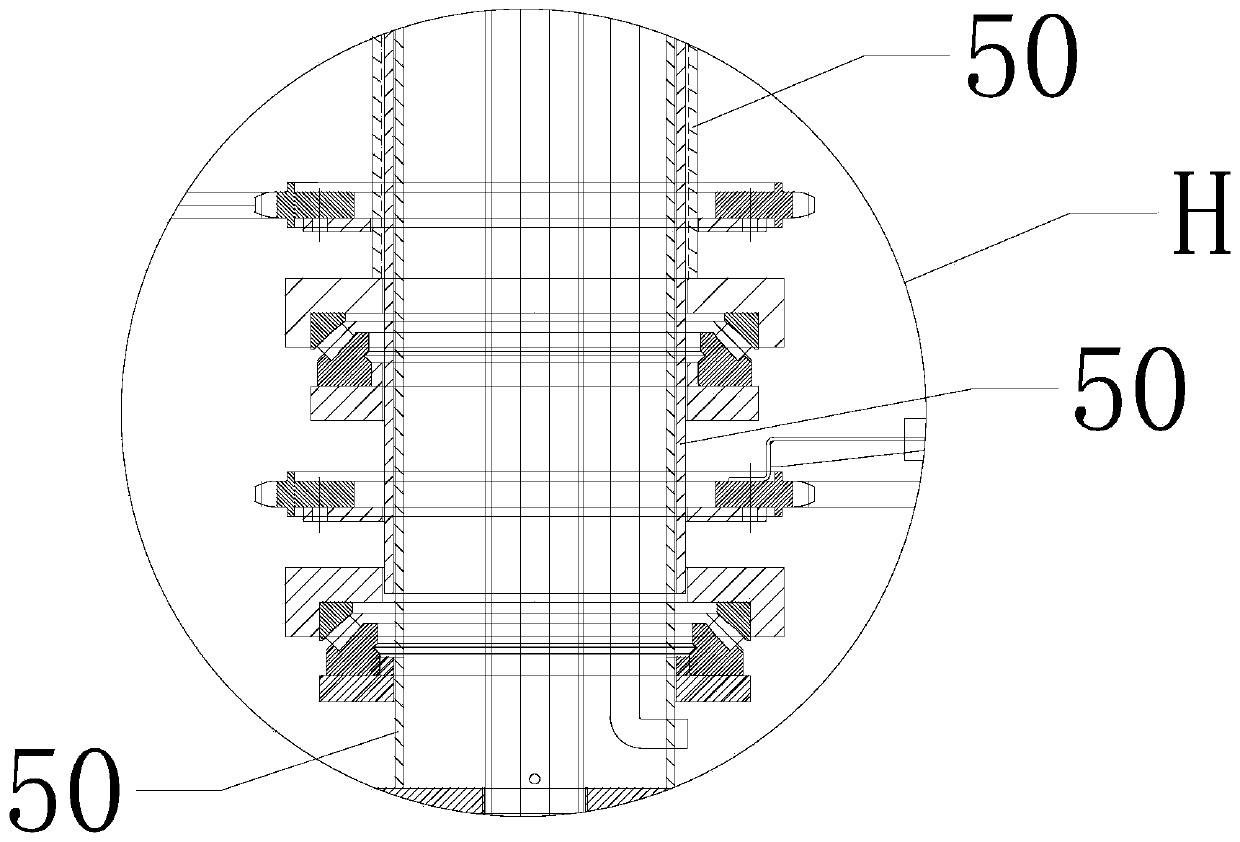

[0021] Such as figure 1 As shown, the present invention provides a cracking gasifier for uniform material mixing, slagging or slagging. The cracking gasifier is used for the treatment of solid waste, and can not only achieve uniform mixing, The slag can also save the furnace bottom space, and the furnace bottom does not need to dig deep into the ground or build a large foundation cap, which is more economical and efficient. Specifically, the cracking gasifier includes a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com