Synchronous vertical lifting system for stereoscopic warehouse

A vertical lifting, three-dimensional warehouse technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of easy jamming, poor synchronization, high noise, etc., and achieve the effect of ensuring simultaneity and high synchronization accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0025] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings, the same reference numerals represent the same or similar components, or the same or similar steps.

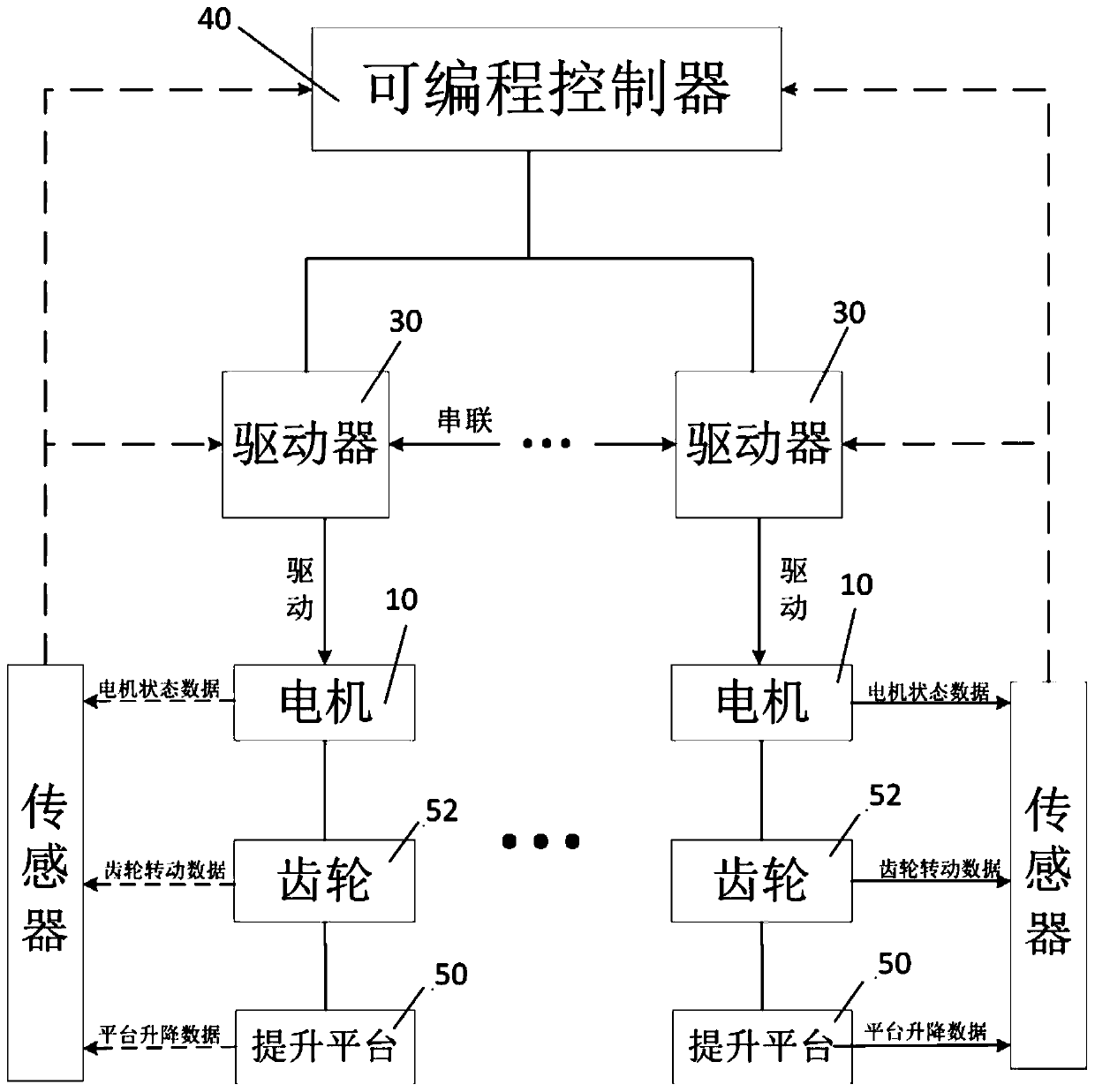

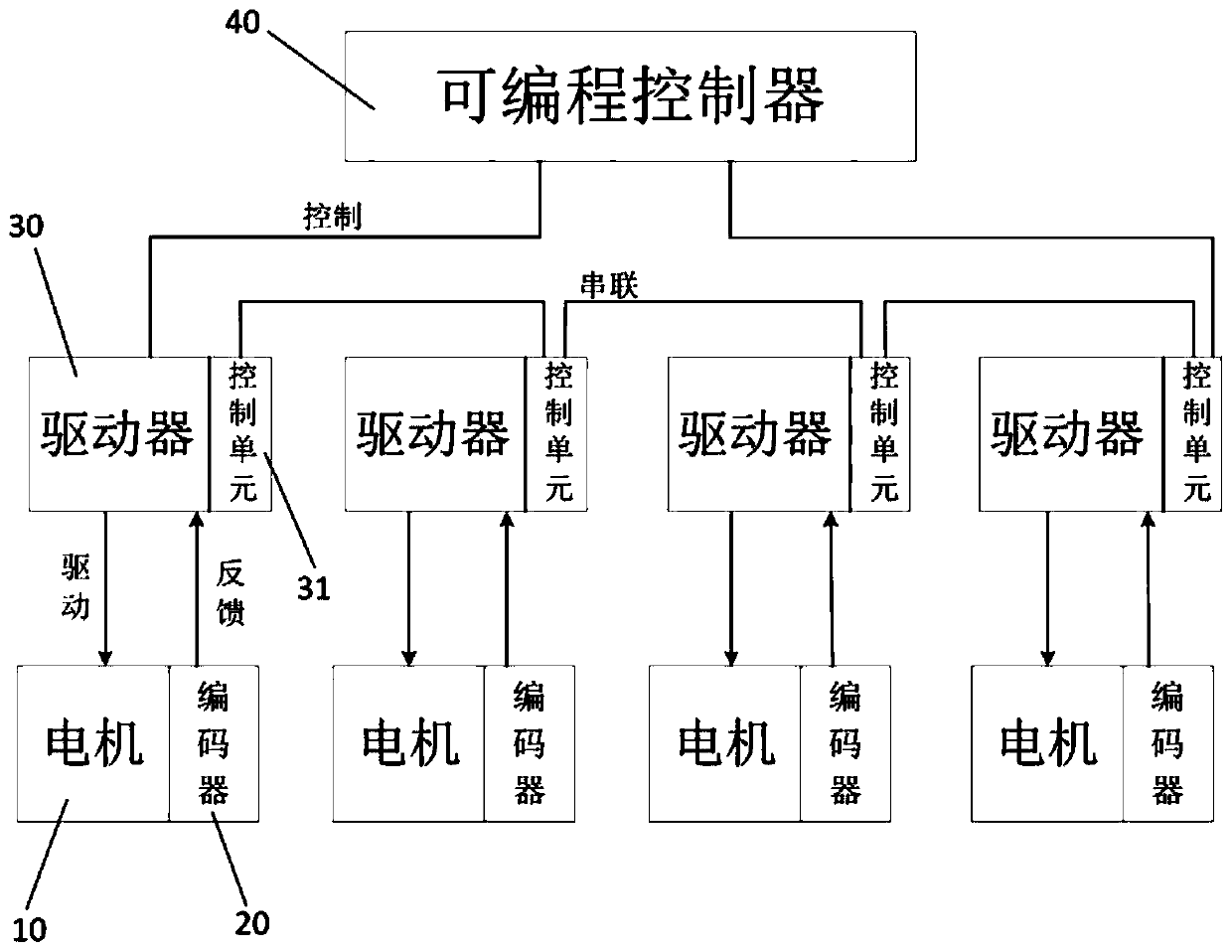

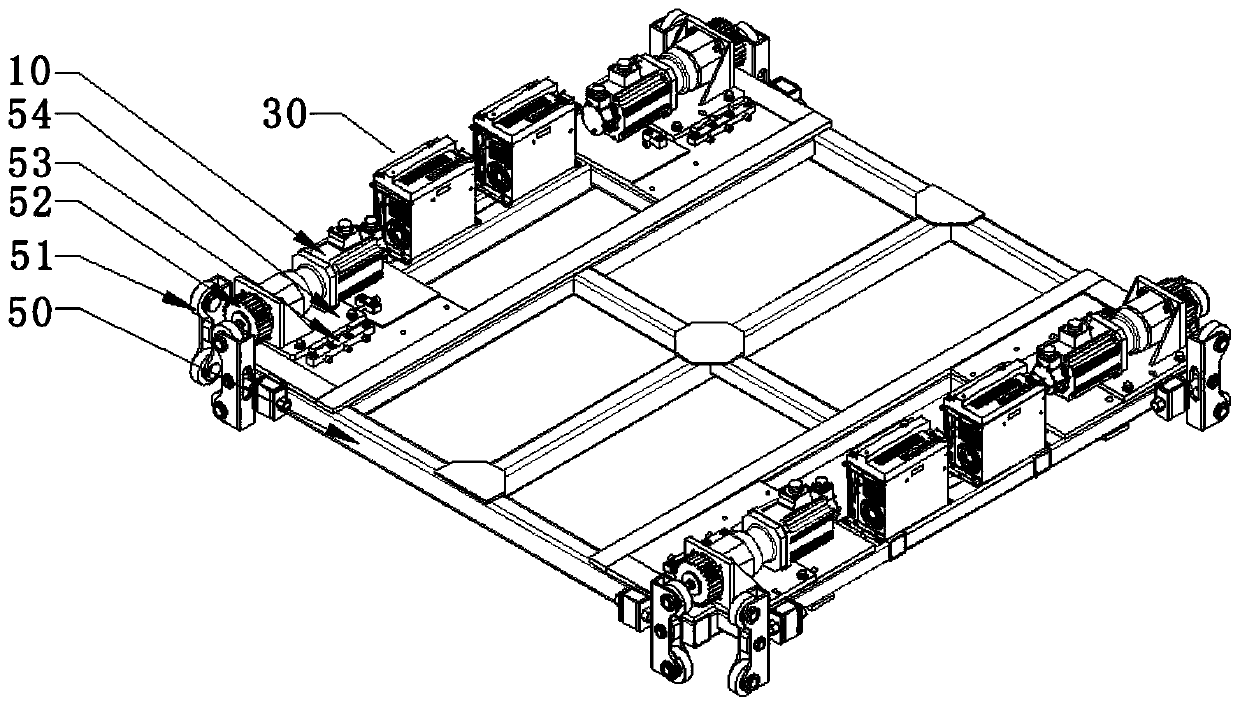

[0026] In the application environment of the three-dimensional warehouse, the handling robot needs to access the goods on the multi-layer shelf, so it is necessary to set up the lifting machine that the handling robot can use to reach different storage layers, and the handling robot with or without load Delivered to the target layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com