A detection method for glaze shrinkage defects of sanitary ceramic products

A technology of sanitary ceramics and detection methods, used in measuring devices, material inspection products, mechanical solid deformation measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the claims, description and the above drawings of the present invention, the terms "comprising", "having" and their

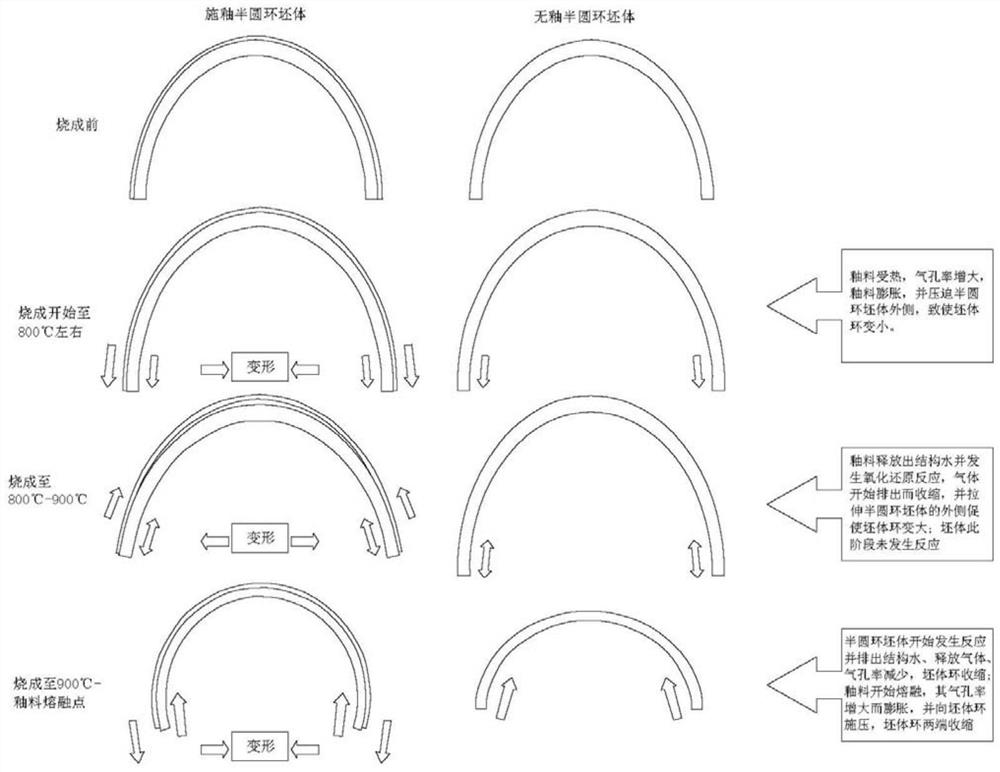

[0027] Referring to Fig. 1, Fig. 1 shows the structural schematic diagram before and after the firing of the semi-circle blank body of glazing in the present embodiment. specific

[0041] The present embodiment proposes that the sintering is carried out by adopting a glazed sector ring blank and an unglazed sector ring blank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com