Proportion optimization method of phosphogypsum-based solid waste filling material to improve filling rate

An optimization method, phosphogypsum technology, applied in chemical statistics, chemical machine learning, chemical data mining, etc., can solve volume instability, reduce the economic benefits of filling mining, increase the cost of filling mining, etc., to achieve cost reduction, Realize the effect of large-scale and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method for optimizing the ratio of phosphogypsum-based all-solid waste filling materials in a phosphogypsum-slag-carbide slag system comprises the following steps:

[0062] Drying and grinding of phosphogypsum solid waste, as well as mineral composition analysis and particle size testing.

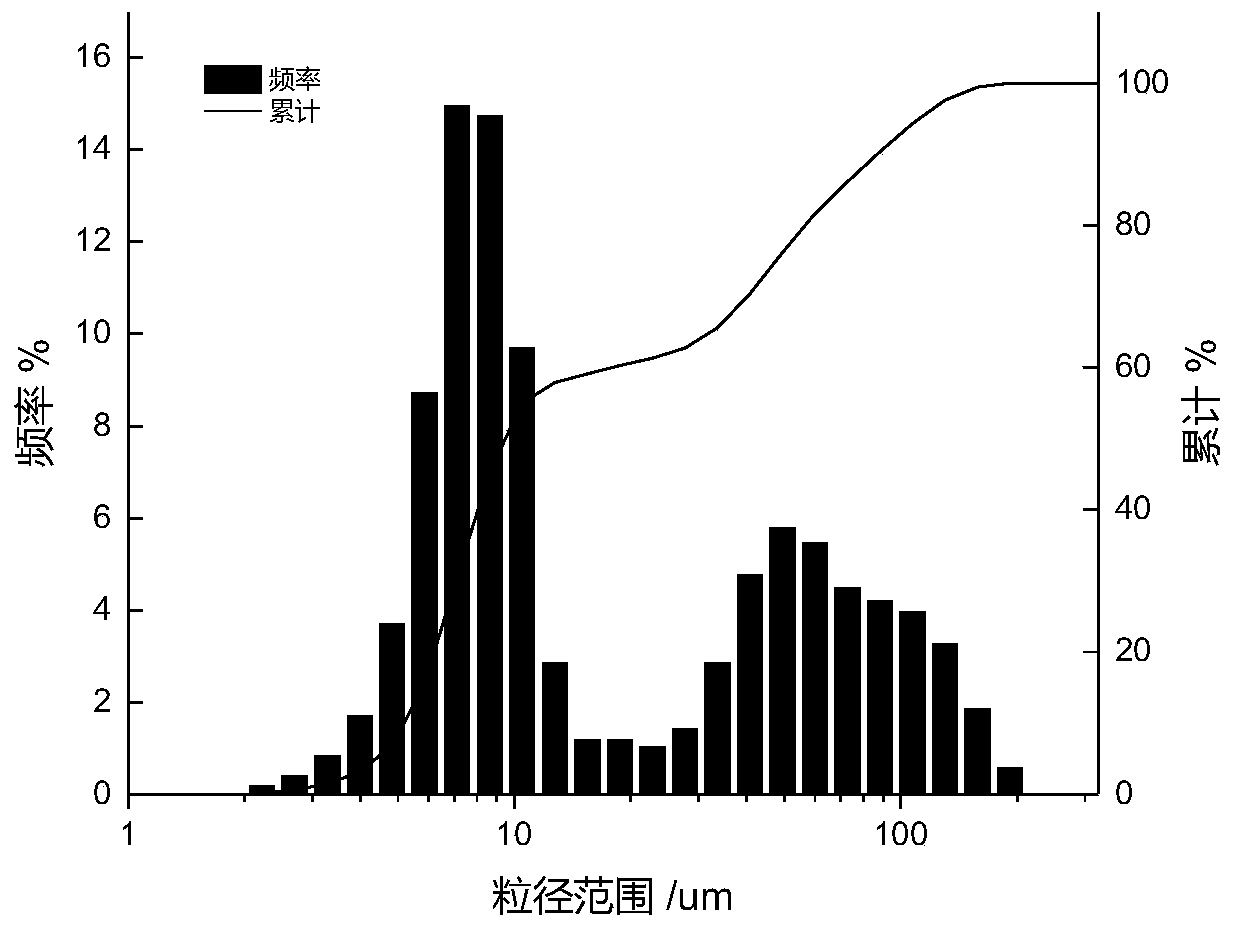

[0063] The results of mineral composition analysis of phosphogypsum in the filler of phosphogypsum-slag-carbide slag system are shown in Table 1. Particle size gradation distribution curve see figure 1 .

[0064] Table 1: Mineral composition analysis results of phosphogypsum solid waste

[0065] Mineral composition P 2 o 5

Fe 2 o 3

Al 2 o 3

MgO CaO SO 4 2-

F acid insoluble matter content / % 1.47 0.48 0.36 2.44 28.6 49.07 0.87 10.17

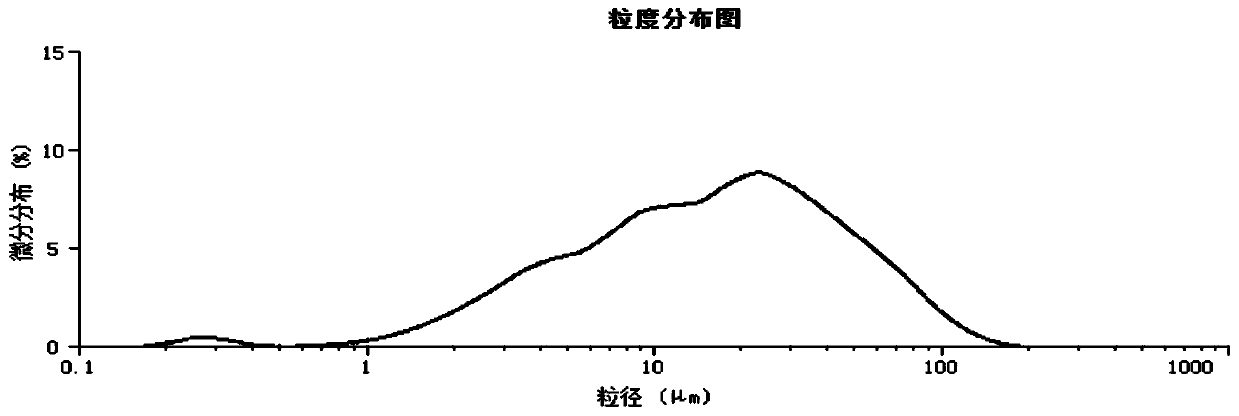

[0066] The particle size distribution curve of slag fine powder in the filler of phosphogypsum-slag-carbide slag system is shown in figure 2 , it can be seen that the content of -45μm ...

Embodiment 2

[0087] A method for optimizing the ratio of phosphogypsum-based solid waste filling materials in the system of phosphogypsum-slag-carbide slag-iron separation slag comprises the following steps:

[0088] Drying, grinding, mineral composition analysis and particle size testing of phosphogypsum solid waste.

[0089] The mineral composition of phosphogypsum in the filler of the phosphogypsum-slag-carbide slag-iron separation tailings system is shown in Table 4.

[0090] Table 4: Phosphogypsum mineral composition of phosphogypsum-slag-carbide slag-iron separation tailings system

[0091] Mineral composition P 2 o 5

Fe 2 o 3

Al 2 o 3

MgO CaO SO 4 2-

F acid insoluble matter content / % 1.76 0.48 0.28 2.44 30.64 53.52 0.45 6.67

[0092] See figure 2 , slag micropowder -45μm fine particle content accounted for 81.9%;

[0093] The mineral composition of slag is shown in Table 5, and the quality factor of slag is Acti...

Embodiment 3

[0114] A method for optimizing the filling ratio of phosphogypsum-slag-carbide slag-fly ash system comprises the following steps:

[0115] Drying, grinding, mineral composition analysis and particle size testing of phosphogypsum solid waste.

[0116] The mineral composition of phosphogypsum in the filling material of phosphogypsum-slag-carbide slag-fly ash system is shown in Table 7.

[0117] Table 7: Mineral composition of phosphogypsum in phosphogypsum-slag-carbide slag-fly ash system

[0118] Mineral composition P 2 o 5

Fe 2 o 3

Al 2 o 3

MgO CaO SO 4 2-

F acid insoluble matter content / % 1.76 0.48 0.28 2.44 30.64 53.52 0.45 6.67

[0119] The particle size distribution curve of slag fine powder of phosphogypsum-slag-carbide slag-fly ash system figure 2 , slag micropowder-45μm fine particle content is 81.9%;

[0120] The mineral composition of slag is shown in Table 8, slag mass coefficient, activity coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com