Transformer substation inspection robot with sub-machine and application method thereof

A technology for inspection robots and substations, which is applied to manipulators, motor vehicles, manufacturing tools, etc., can solve the problems of not being able to meet the safety requirements of substations, low GPS navigation accuracy, and high road maintenance costs, so as to reduce inspection costs and improve The effect of inspection efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

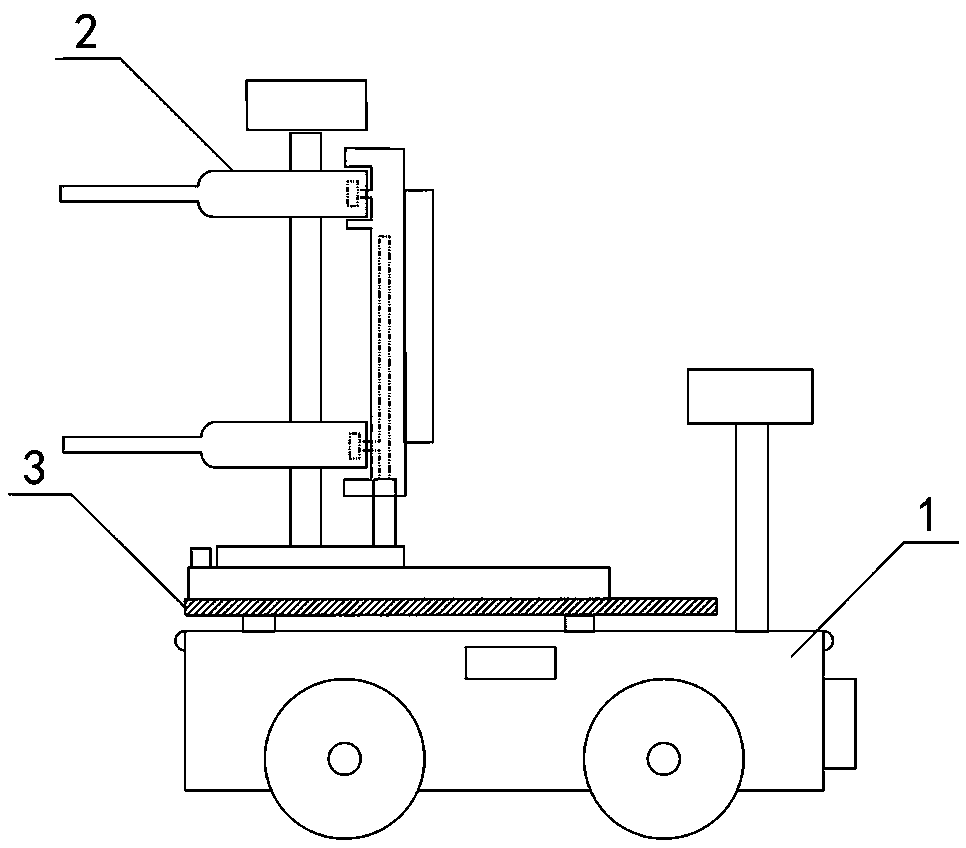

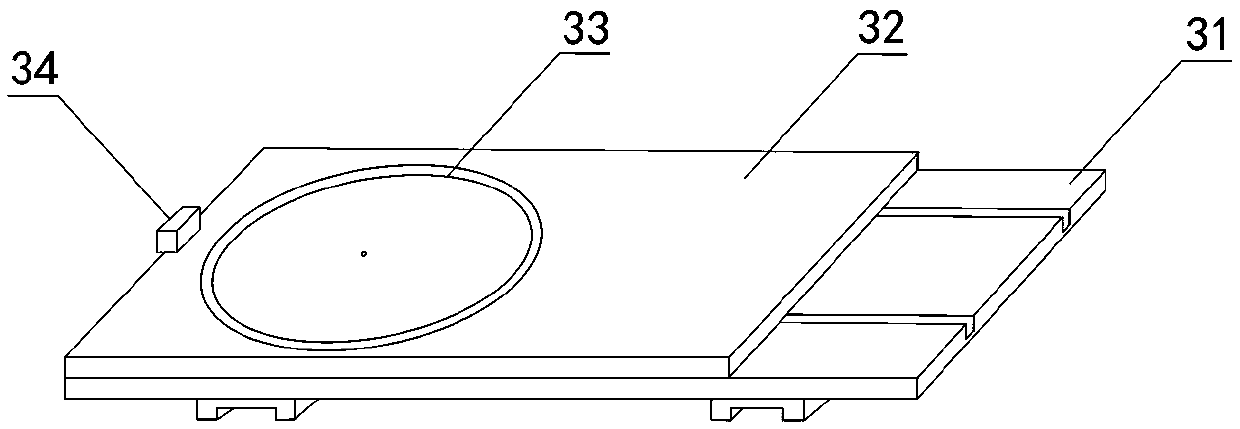

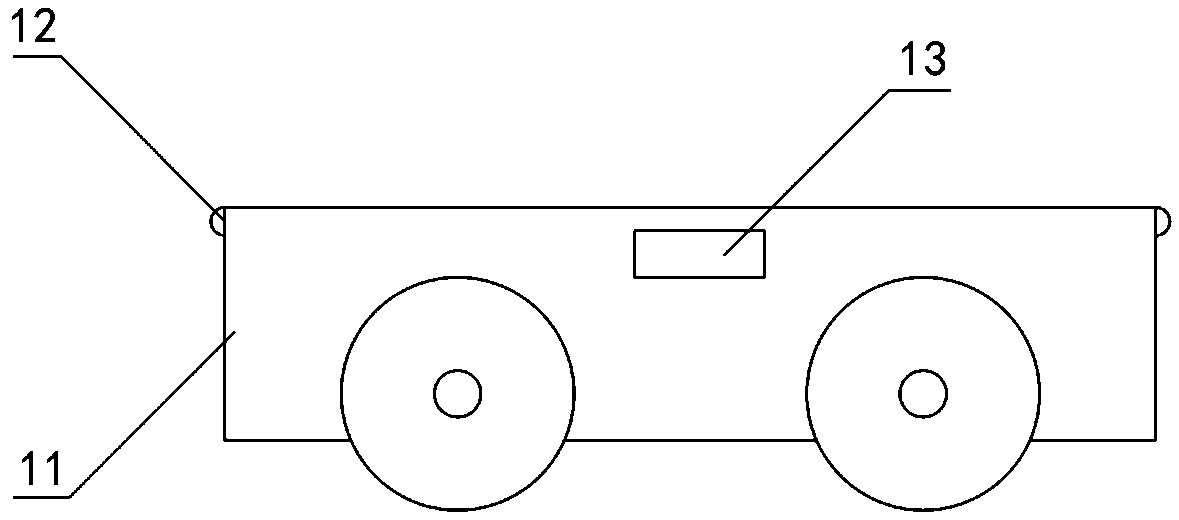

[0035] Such as figure 1 As shown, the substation inspection robot with sub-units in this embodiment includes a ground mobile mechanism 1 and a pole-climbing sub-machine 2 that can independently perform inspection operations. The top of the ground mobile mechanism 1 is provided with an electromagnetic adsorption mechanism 3, and in the docking state The pole climbing sub-machine 2 is fixed on the electromagnetic adsorption mechanism 3 by magnetic adsorption. In this embodiment, the substation inspection robot with sub-units passes through the ground mobile mechanism 1 and the pole-climbing sub-machine 2 that can independently perform inspection operations. When the substation inspection robot with sub-units performs inspections on the ground, the electromagnetic adsorption mechanism 3 Power on and fix the pole climbing machine 2 to ensure the safety of ground inspection; when it is necessary to inspect the substation at a high level, the electromagnetic adsorption mechanism 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com