Battery pole piece rolling device and method

A battery pole piece and roll pressing technology, which is applied in battery electrodes, electrode rolling/calendering, electrode manufacturing, etc., can solve problems such as broken tape and foil wrinkling, so as to solve the problem of wrinkling and broken tape and improve production efficiency , The effect of reducing the cost of reworked materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] like Figure 1~2 As shown, this embodiment provides a battery pole piece rolling device, which includes an unwinding assembly 1, a cutting assembly 2, a rolling assembly 3, a rolling assembly 4 and a winding assembly 5, which are sequentially connected by transmission. Comprising a slitting knife shaft and several slitting knives arranged on the slitting knife shaft, the rolling assembly 3 includes an upper pressing roller 31 and a lower pressing roller 32 arranged below the upper pressing roller 31 .

[0030] In an embodiment of the battery pole sheet rolling device according to the present invention, the unwinding assembly 1 includes an unwinding roller and an unwinding regulating roller arranged in sequence. The unwinding adjustment roller can swing left and right relative to the center line, and its position can be adjusted to ensure the accurate unwinding position of the coated pole piece.

[0031] In one embodiment of the battery pole piece rolling device accordi...

Embodiment 2

[0036] like image 3 As shown, the present embodiment provides a rolling method, comprising the following steps:

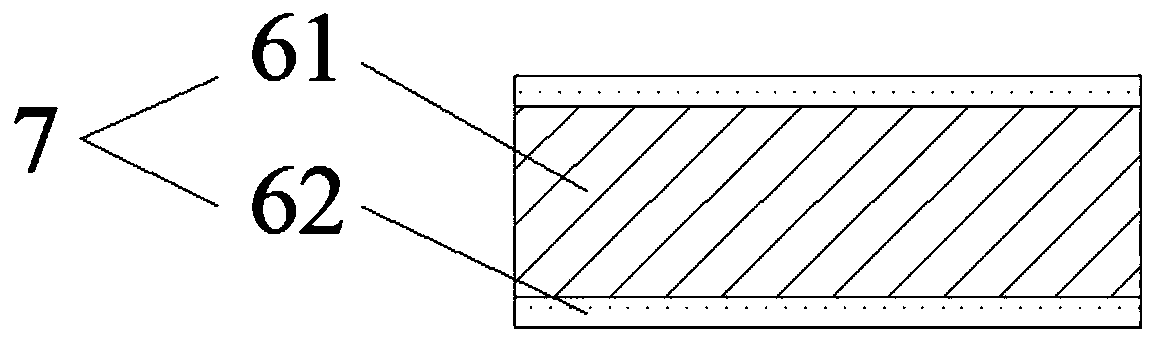

[0037] Step 1: Apply the slurry on the surface of the foil by zebra coating and dry to obtain a single sheet of foil 6 with several dressing areas 61;

[0038] Step 2, cutting the individual foil material 6 to obtain several individual foil materials 7;

[0039] Step 3, rolling the single foil 7 to obtain the rolled single foil 7;

[0040] Step 4, winding up the single strip of foil material 7 after rolling, and the rolling is completed.

[0041] In an embodiment of the rolling method according to the present invention, in step one, empty foil areas 62 are connected to both sides of the dressing area 61 .

[0042] In an embodiment of the rolling method according to the present invention, in step 2, cutting the single foil 6 is specifically cutting along the empty foil region 62 between any two dressing regions 61 .

[0043] In an embodiment of the rolling meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com