Automatic material assembling structure

A technology for assembling structures and materials, applied in the field of automated material assembling structures, can solve the problems of high labor intensity, low degree of automation, low work efficiency, etc., and achieve the effect of reducing processing cycle time, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

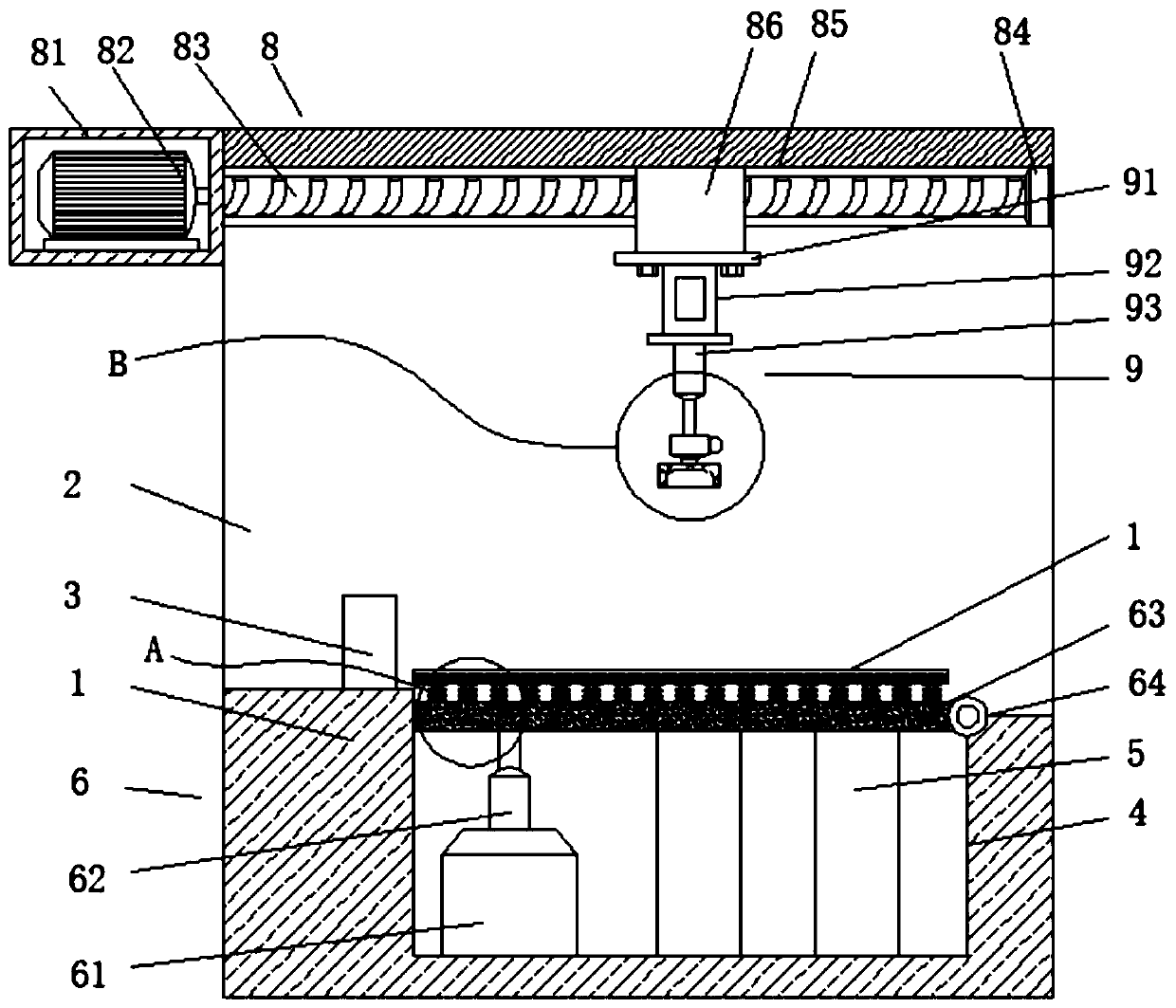

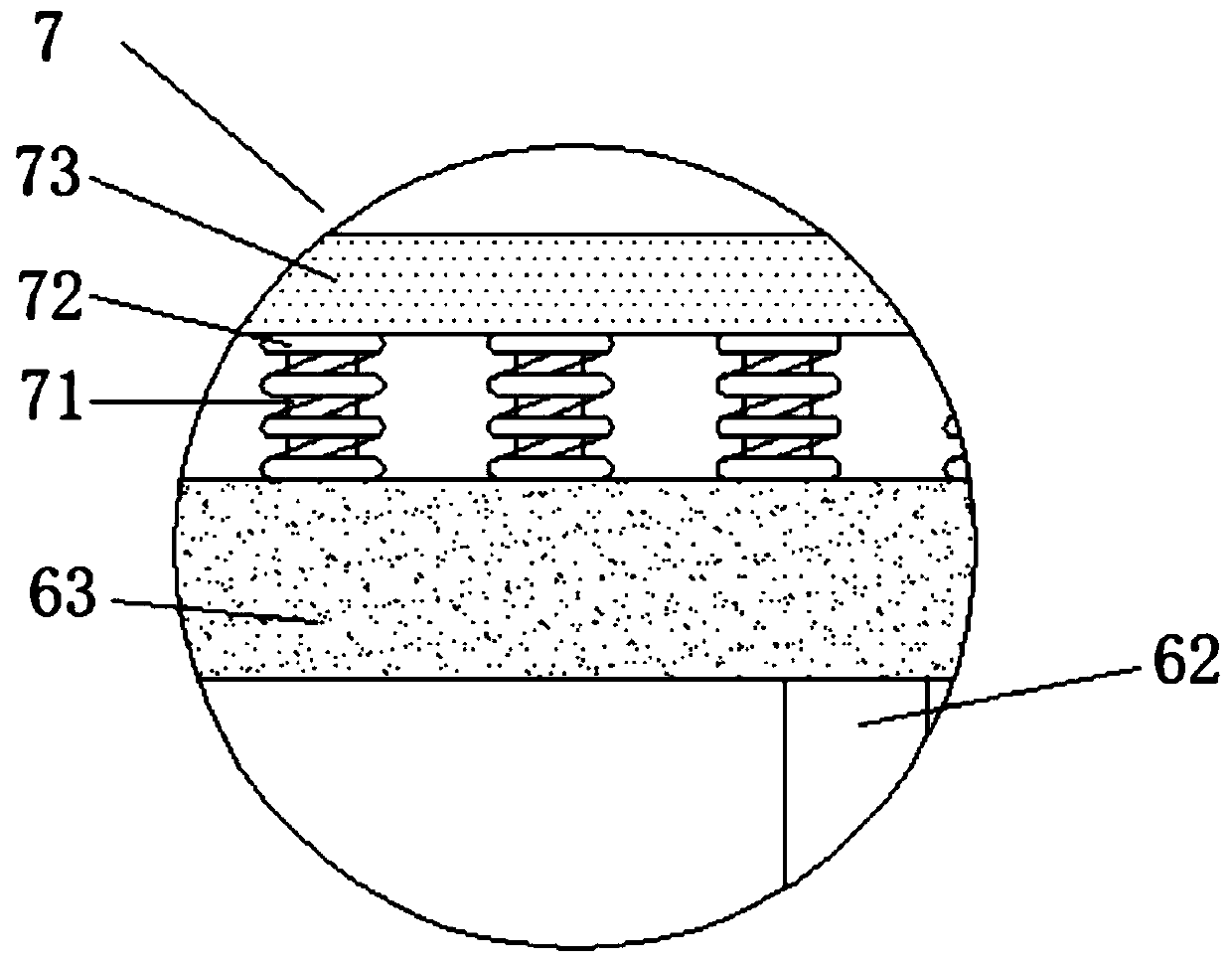

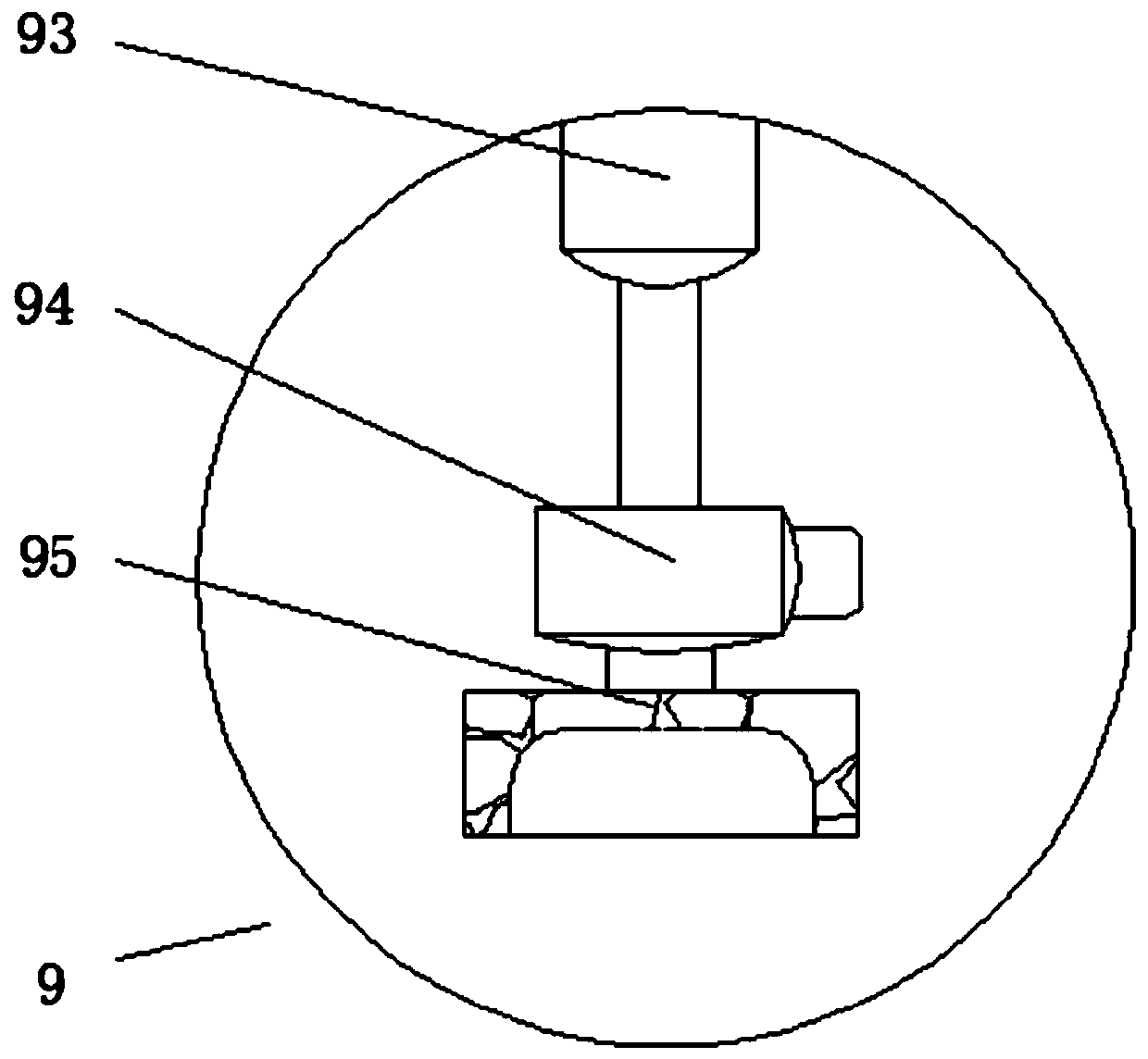

[0023] Such as Figure 1-5 As shown, an automatic material assembly structure includes a base 1, an organic casing 2 is fixedly installed on the upper end of the base 1, a limit block 3 is installed on one side of the upper end of the base 1, a rectangular slot 4 is opened on the base 1, and the rectangular slot 4 is fixedly installed There are two spacer columns 5, and a telescopic mechanism 6 is installed on one side of the two spacer column 5, and a support mechanism 7 is installed on the telescopic mechanism 6, and a sliding mechanism 8 is installed on the inner wall of the upper end of the support mechanism 7, the top of the casing 2, and the sliding mechanism 8. The lower end is equipped with a pressing mechanism 9, and a controller 10 is fixedly installed on the outer wall of the casing 2. By setting the telescopic mechanism 6, the supporting mechanism 7, the sliding mechanism 8 and the pressing mechanism 9, the degree of automation of the device is relatively high, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com