Distribution network automatic working platform

A technology of distribution network automation and working platform, applied in switchgear, electrical components, etc., can solve the problems of cumbersome construction or disassembly of insulating scaffolding, physical discomfort of maintenance personnel, and small movable space, and achieves easy transportation, storage, storage, and construction. The effect of high efficiency and large movable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

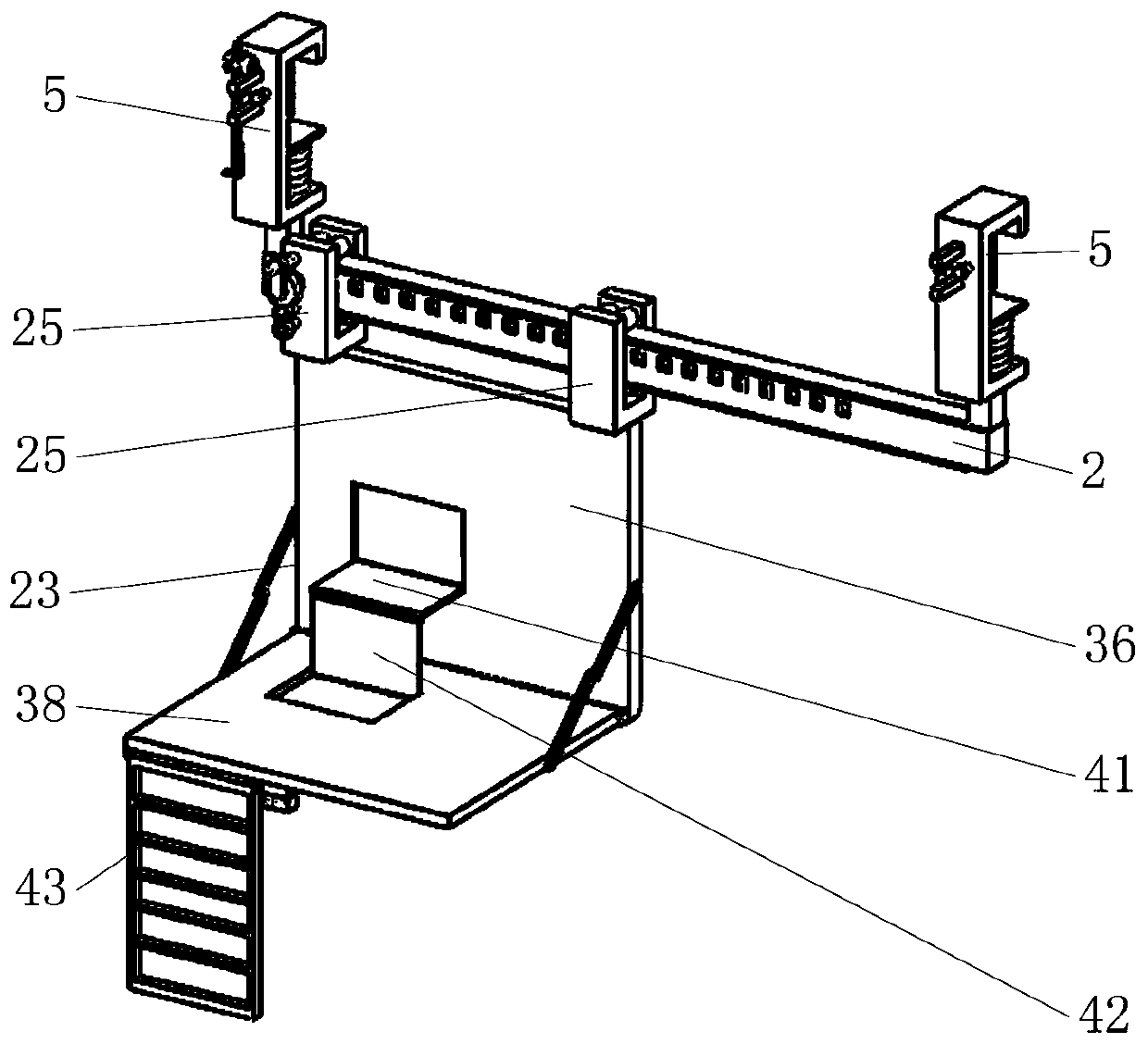

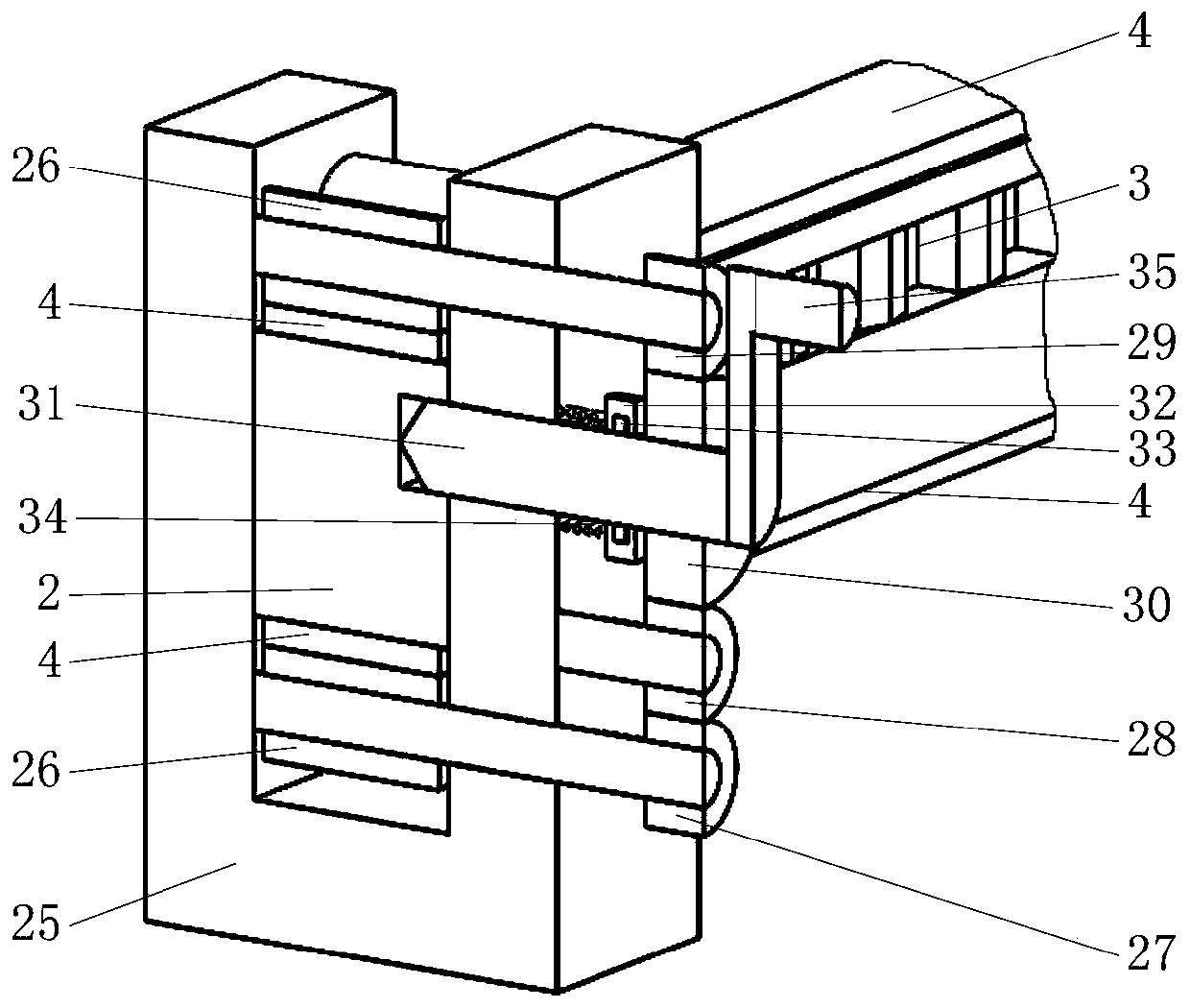

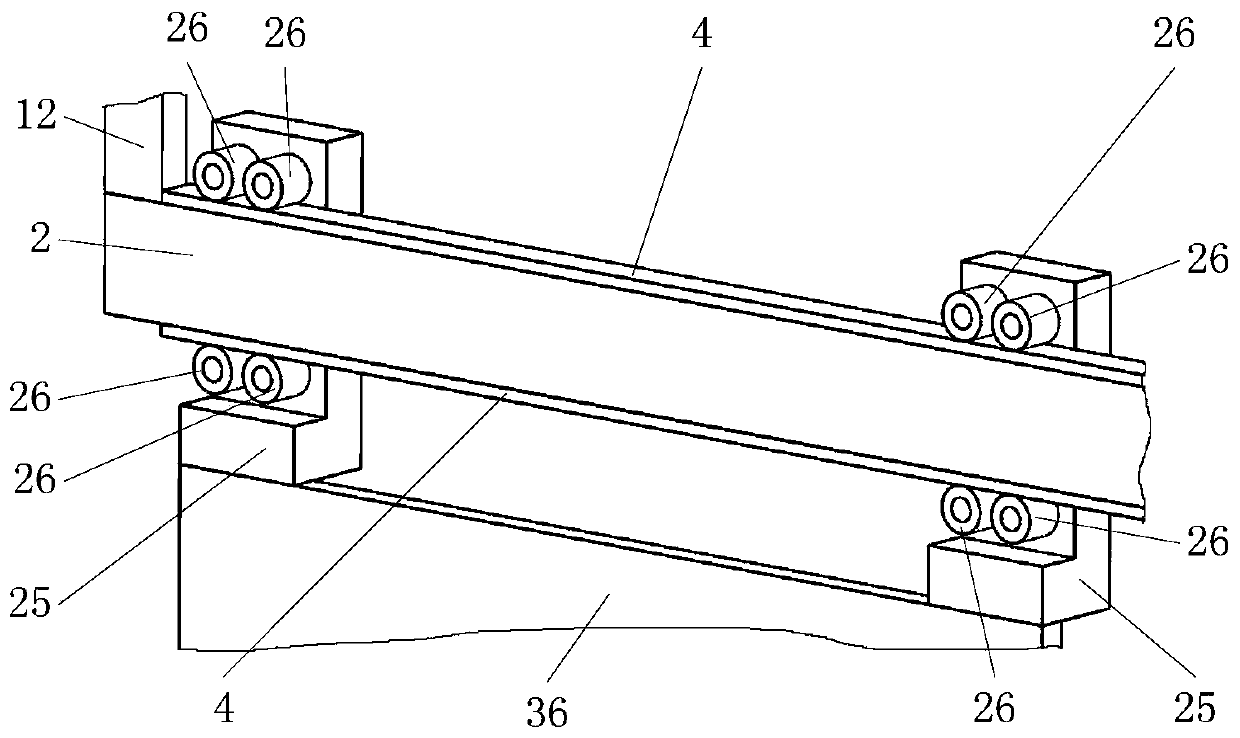

[0037] Such as figure 1 As shown, it includes beam 2, hook mechanism 5, console mechanism 23, wherein as Figure 4 , 13 As shown, the two ends of the crossbeam 2 are symmetrically equipped with two hook mechanisms 5 that cooperate with the distribution box support beam 48; the console mechanism 23 between the two hook mechanisms 5 slides reciprocally on the crossbeam 2; Figure 4 , 6 As shown, one of the hook mechanisms 5 has a load-limiting marking structure 49 that matches the load-bearing capacity of the distribution box support beam 48 .

[0038] Such as Figure 5 As shown, the above-mentioned hook mechanism 5 includes a C-shaped hook 6, a clamping plate 8, a guide bar 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com