Ground leveling robot and construction method thereof

A robot and ground technology, applied in construction, building structure, construction material processing, etc., can solve problems such as slow construction efficiency, small scraper size, and large travel resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

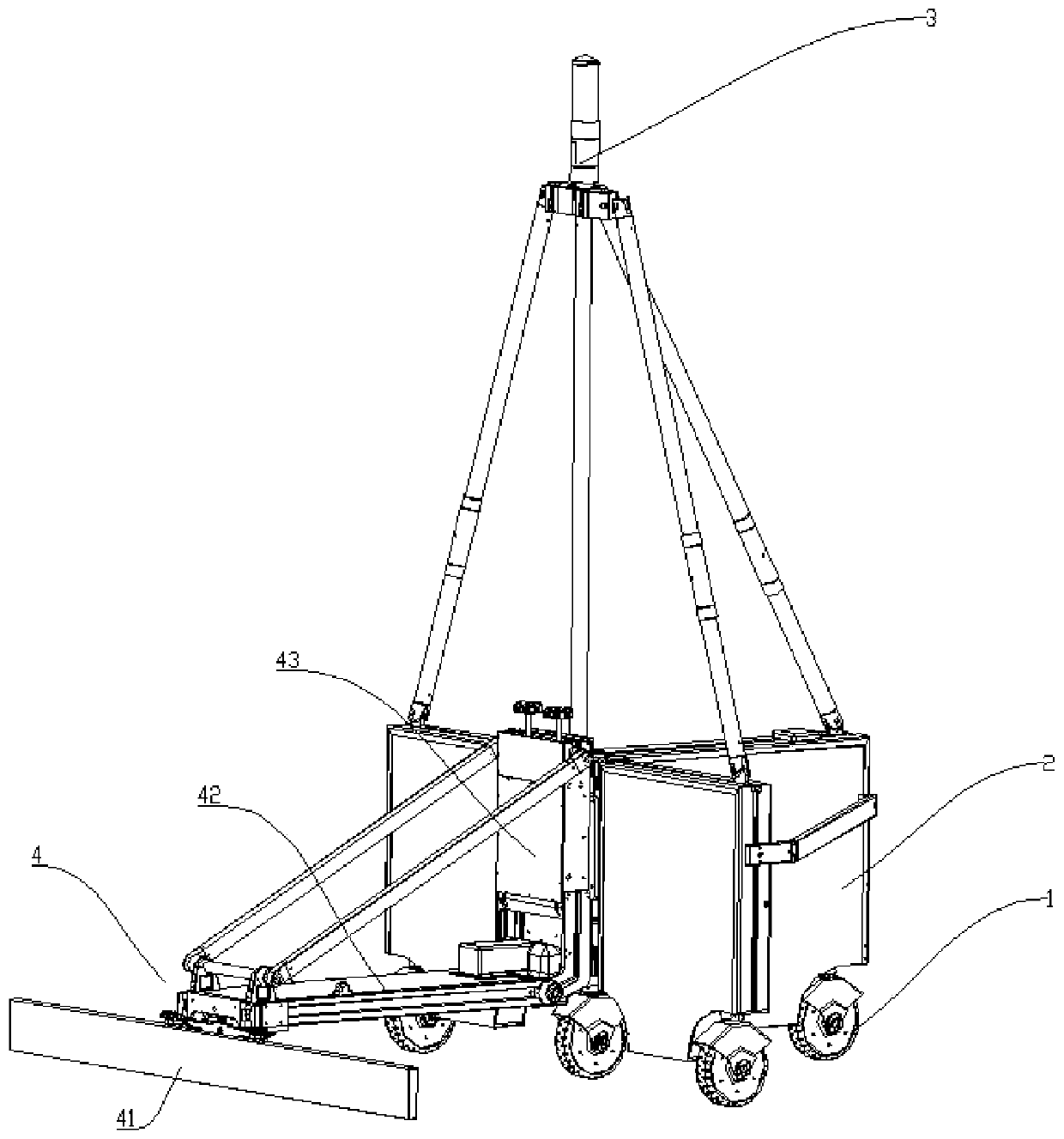

[0045] like figure 1 As shown, the ground leveling robot of the present invention includes a base 2, a receiving sensor 3 arranged above the base, and a plurality of retractable roller devices 1 located at the bottom of the base, and a tilt detection sensor is provided inside the base.

[0046] The inclination degree detection sensor drives the corresponding retractable roller device to expand and contract according to the inclination degree of the detected base, so that the base as a whole remains in a horizontal state all the time. For example, when the base is tilted towards a certain telescopic roller device, the telescopic roller device in this direction is controlled to rise, or the telescopic roller device corresponding to the telescopic roller device is controlled to descend; Require. The process of above-mentioned judgment and adjustment can be finished manually, also can be finished by control system (such as single-chip microcomputer);

[0047] Ground leveling wor...

Embodiment 2

[0050] In order to make the construction surface obtained by the ground leveling working head 4 at each construction position be at the same height, manual or mechanical auxiliary means are usually required to set the reference marking line. Especially when the bottom surface to be constructed is uneven, relevant auxiliary means should be designed to overcome it.

[0051] In this embodiment, the ground leveling robot also includes a laser receiver 3, the laser receiver is used to receive an external laser reference beam or laser reference plane as a reference, and it has been known whether the current telescopic length of the telescopic roller device satisfies Construction requirements.

[0052] Considering that debris is usually piled up near the ground to block the laser reference beam or reference plane, the laser receiver can also be installed on a support rod fixedly connected to the base to increase its height to avoid obstacles blocking the laser reference plane. like ...

Embodiment 3

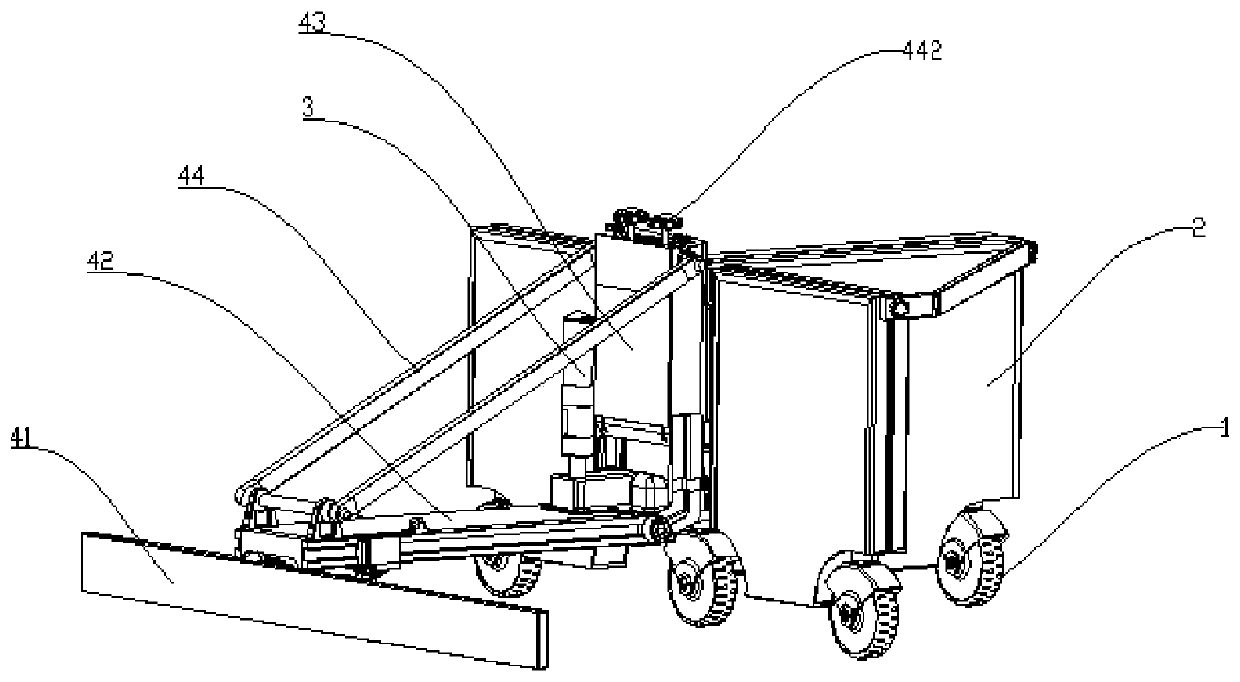

[0058] like figure 2 As shown, compared with Embodiment 2, the difference of Embodiment 3 is that the laser receiver is installed on the mobile platform. During each commissioning work, the ground leveling work head should be at the same position of the base; that is, the lifting platform is lifted to a fixed commissioning initial position C0 relative to the base, and the commissioning and working process are basically the same as the installation of the laser receiver. Same on the base, the steps are as follows:

[0059] 1) The ground leveling robot moves to the position to be constructed, and the lifting platform rises and falls to a fixed position C0 relative to the base, which is the initial debugging position; the inclination degree detection sensor detects the inclination of the base, and passes the retractable roller The device (1) stretches to adjust the base to a horizontal state; set a horizontal reference laser plane, and under the premise of ensuring that the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com