Efficient recovery device of industrial high-temperature material sensible heat system and method

A high-temperature material and recovery device technology, applied in waste heat treatment, heat storage equipment, indirect heat exchangers, etc., can solve problems such as heat imbalance, sensible heat waste, unreasonable system design, etc., and achieve huge economic and social benefits , Sensible heat heat transfer efficiency is improved, and the effect of solving the problem of sensible heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

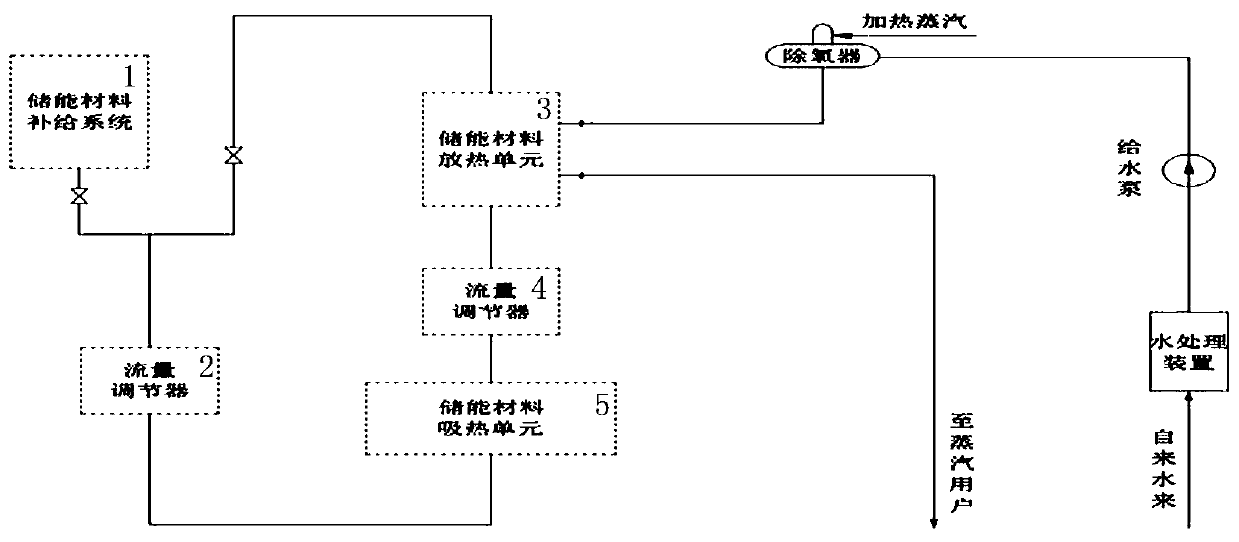

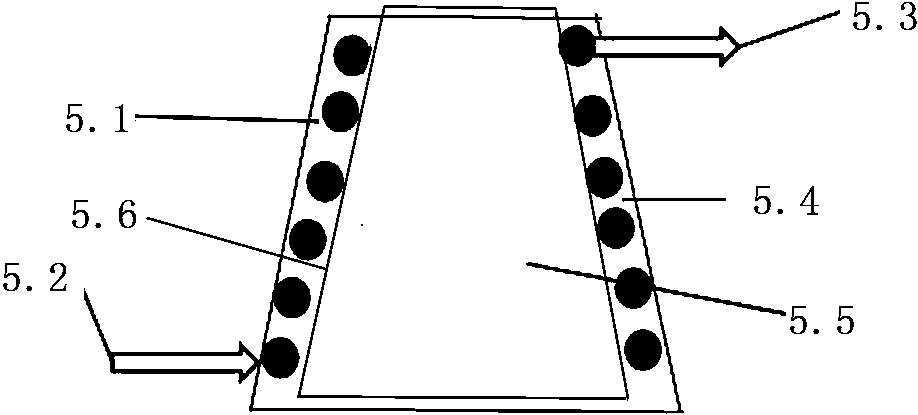

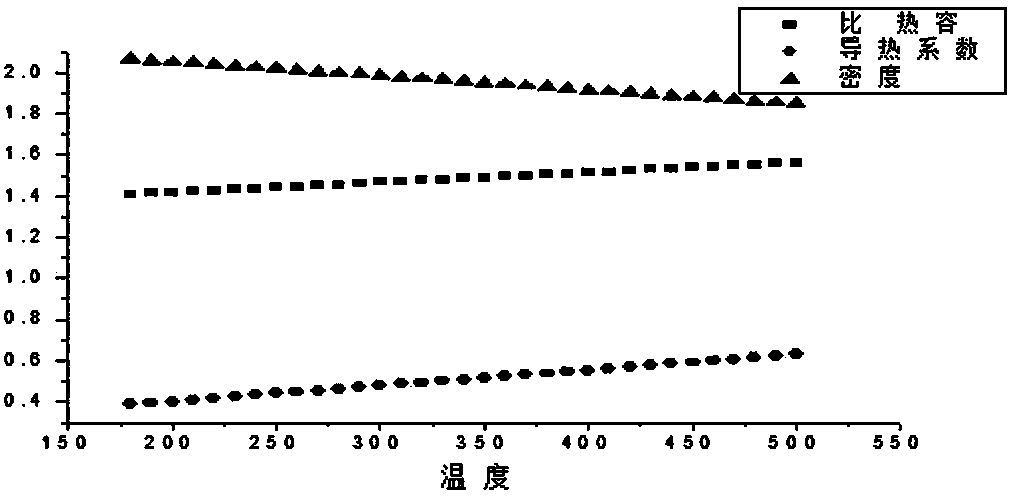

[0033] Such as Figure 1-2 As shown, the high-efficiency recovery device for the sensible heat system of industrial high-temperature materials includes an energy storage material heat-absorbing heat-exchanging unit 5, and the energy-storage material heat-absorbing heat-exchanging unit 5 has a first Three outlets, the third outlet is connected with an energy storage material exothermic heat exchange unit 3, the energy storage material exothermic heat exchange unit 3 and the energy storage material endothermic heat exchange unit 5 are connected in series,

[0034]The energy storage material heat absorption heat exchange unit 5 has a third inlet for the low-temperature energy storage material to flow in, and the energy storage material flow regulator-2 is installed on the third inlet, and the energy storage material heat release heat exchange unit 3 An energy storage material flow regulator 2 4 is installed on the pipeline between the inlet and the third outlet of the energy stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com