Double-layer overlapping PCB hole opening process equipment and process method thereof

A kind of process equipment and overlapping technology, applied in the direction of metal processing, etc., can solve the problems of easy deformation, chips and chips that cannot be discharged in time, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

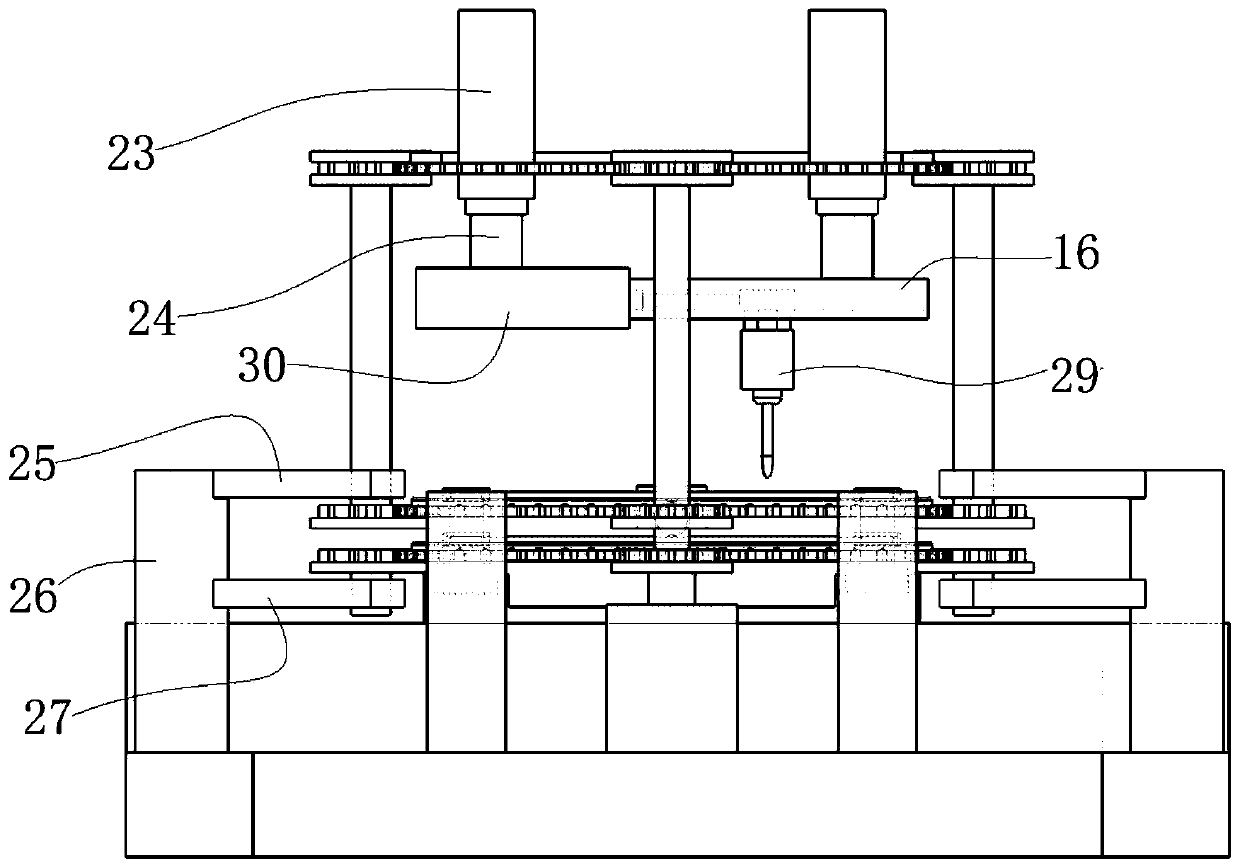

[0047] as attached Figures 1 to 13 The shown double-layer overlapping PCB drilling process equipment includes an equipment platform 1, and a first pcb board to be perforated 19.1 and a second perforated pcb board 19.2 with a square outline are overlapped on top of the equipment platform 1 ;

[0048] It also includes two sets of pcb board positioning mechanisms, each set of pcb board positioning mechanisms includes four corner wrapping parts 9 in a vertical triangular structure, and corner wrapping openings 60 are provided on the sides of each of the corner wrapping parts 9; The four corners of the first pcb board 19.1 to be perforated and the second pcb board 19.2 to be perforated are inserted into the corner wrapping openings 60 of the four corner wrappers 9 correspondingly;

[0049] A hole opening mechanism is also provided above the first pcb board to be holed 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com