Adjusting device for optical centering instrument

An adjustment device and a centering instrument technology, which is applied in the field of optical centering instruments, can solve the problems of inconvenient operation and low adjustment precision of optical centering instruments, and achieve the effects of improving efficiency, simple structure, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

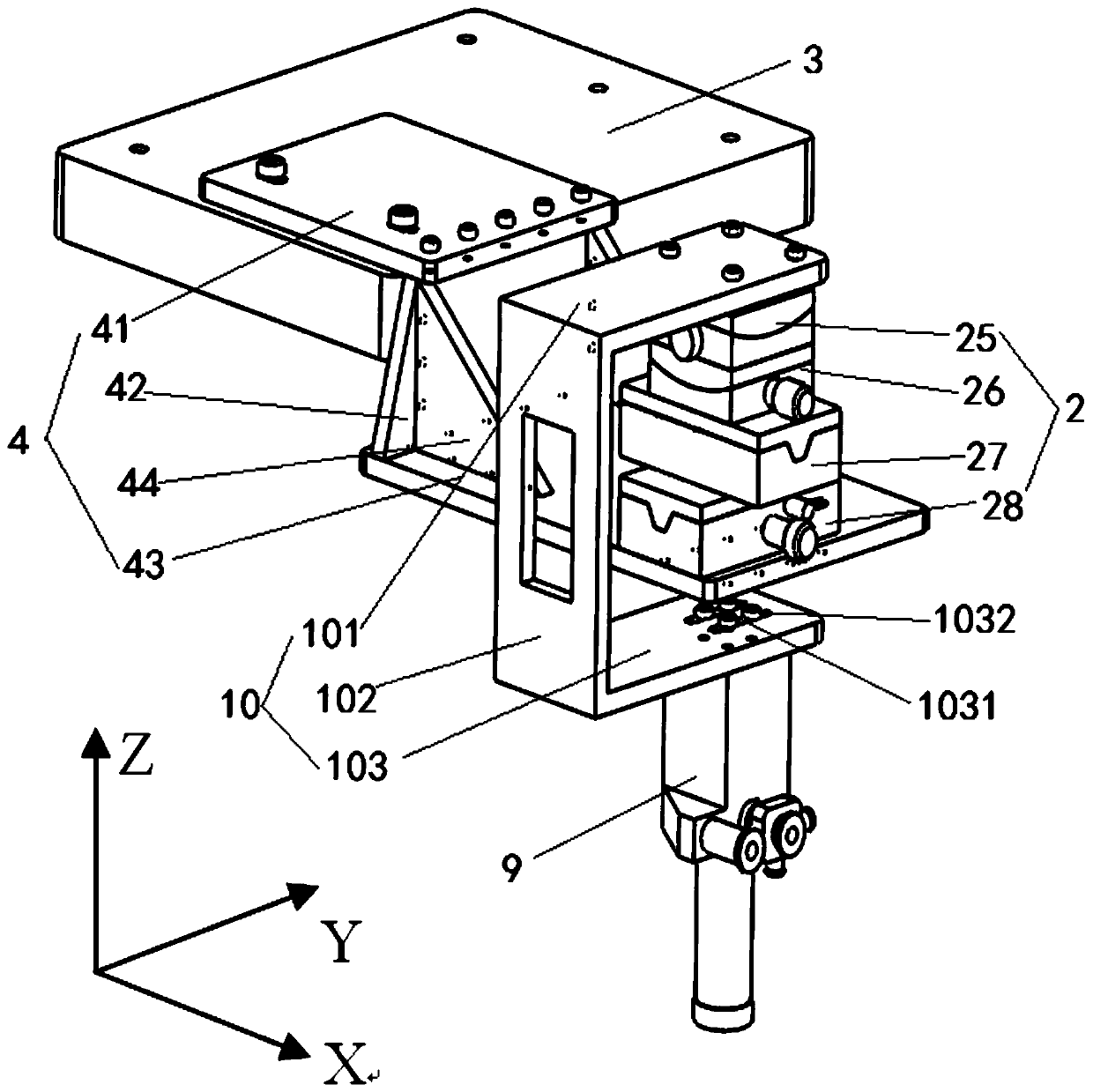

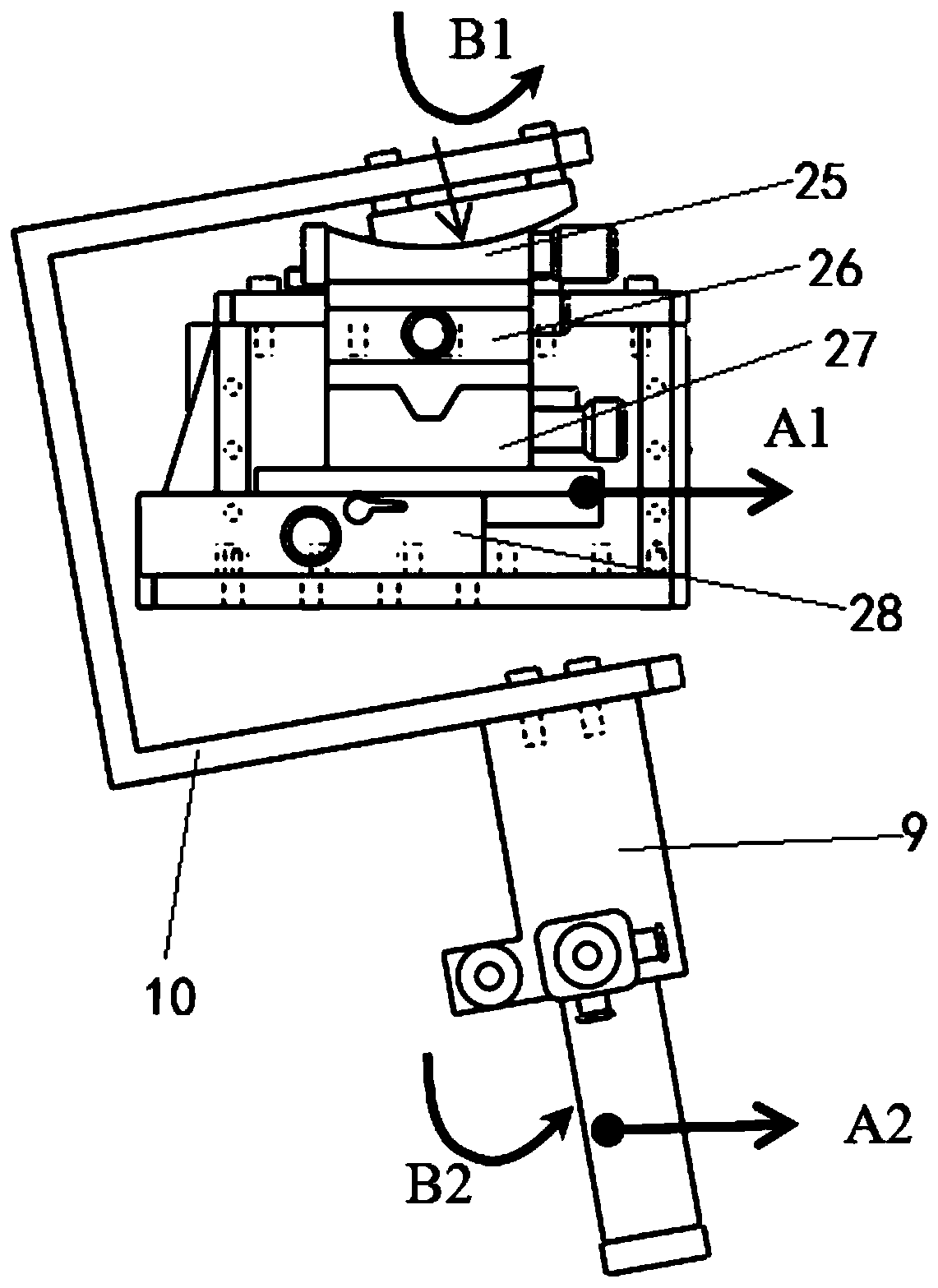

[0052] to combine Figure 1 to Figure 4 As shown, the four-dimensional adjustment device for the optical centering instrument of this embodiment includes a four-dimensional adjustment mechanism 2, a connecting frame 4, and an adapter frame 10; the four-dimensional adjustment mechanism 2 includes an X-axis angle adjustment platform 25 arranged sequentially from top to bottom , Y-axis angle adjustment platform 26, X-axis translation adjustment platform 27 and Y-axis translation adjustment platform 28, and constitute a whole.

[0053] Among them, the X-axis angle adjustment table 25 has the same structure as the Y-axis angle adjustment table 26, and the direction of the angle adjustment center axis is vertical, and the adjustment range is -10°~10°; the X-axis translation adjustment table 27 and the Y-axis translation adjustment table 28 have the same structure, and the translation directions are perpendicular to each other, and the adjustment range is -37.5mm to 37.5mm, which mee...

Embodiment 2

[0061] combine Figure 2 to Figure 4 As shown, the structure of the four-dimensional adjustment device of this embodiment is basically the same as that of Embodiment 1, the difference is that the adapter frame 10 includes an upper horizontal plate 101, an adapter vertical plate 102 and a lower horizontal plate 103; the upper horizontal plate 101 and the lower horizontal plate 103 are located on the same side of the transfer vertical plate 102, and one end of the upper horizontal plate 101 and the lower horizontal plate 103 are respectively vertically connected with the two ends of the transfer vertical plate 102 to form a C-shaped structure of the transfer frame 10, The upper end surface of the X-axis angle adjustment platform 25 is connected with the lower end surface of the upper horizontal plate 101; the optical centering device 9 is connected with the lower end surface of the lower horizontal plate 103; Located below the four-dimensional adjustment mechanism 2 , the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com