Multi-curvature ceiling structure in tall and large space and its construction method

A high-space, multi-curvature technology, applied in the direction of ceiling, building components, building structure, etc., can solve the problems of easy installation deviation, difficult surface design, large workload, etc., to avoid material waste, reliable node connection, occupying Small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

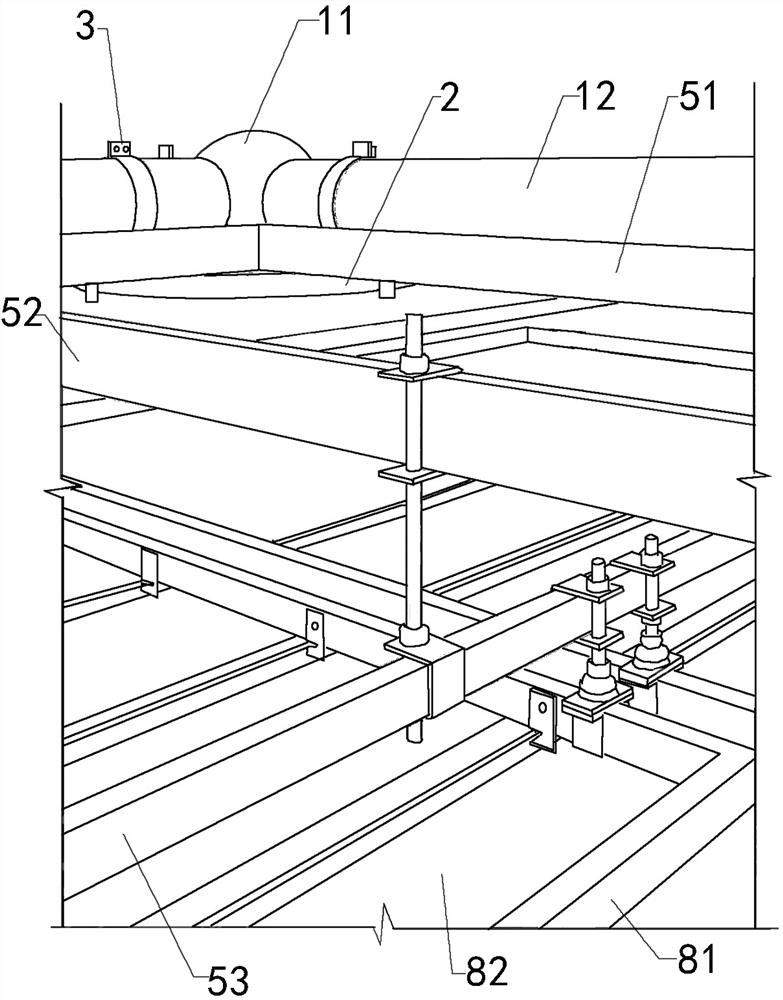

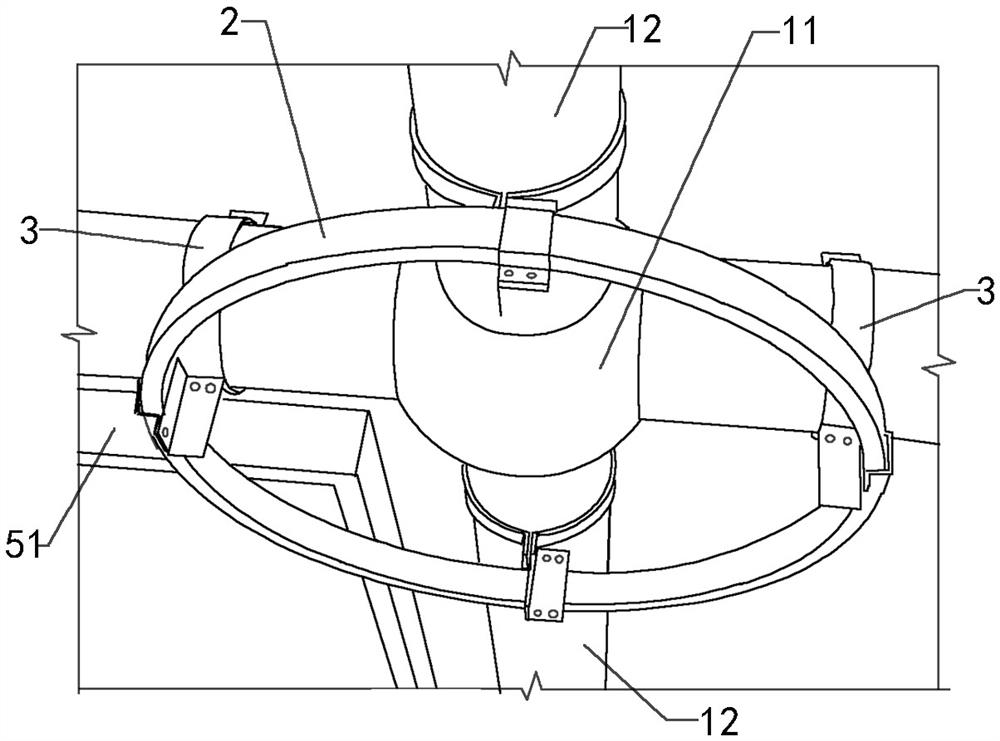

[0047] Such as Figure 1 to Figure 9 As shown, the high space multi-curvature ceiling structure of the present invention is suspended under the steel structure truss. The steel structure truss includes hollow balls 11 located at nodes, and lower chords 12 fixedly connected to the hollow balls 11. The ends of the lower chords 12 are connected to the hollow The ball 11 is fixedly connected, and the specific connection method is welding or integrally made.

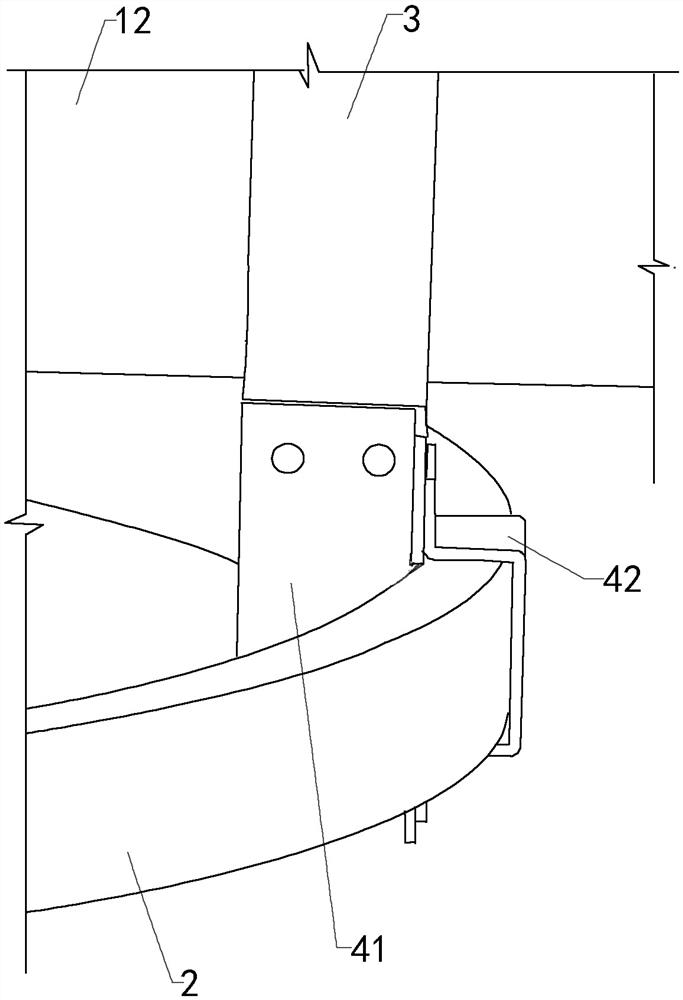

[0048] The suspended ceiling structure includes a hoop assembly located under the hollow ball 11, a keel frame detachably connected to the hoop assembly, and a decorative panel suspended under the keel frame.

[0049] Such as figure 2 As shown, the hoop assembly includes a hoisting frame support 2 positioned directly below the hollow ball 11 and arranged horizontally. The hoisting frame support 2 is connected and fixed by connecting the hoop 3 with the lower chord 12 around the hollow ball 11; the hoisting frame support 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com