Robot intelligent oiling equipment

A technology of robots and equipment, applied in the directions of manipulators, packaging, liquid distribution, conveying or transfer devices, etc., can solve problems such as the inability to meet the refueling needs of large-flow refueling vehicles, irregular leakage of mechanical arms, and increased cost of gas stations. Achieve the effect of automatic operation, space saving and flexible fueling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

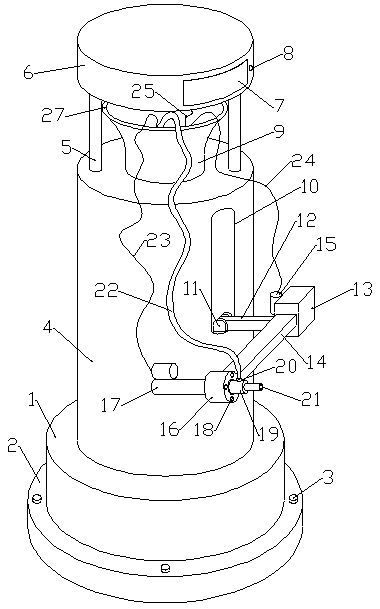

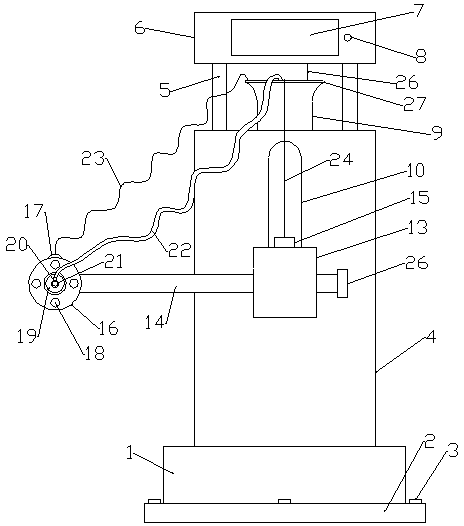

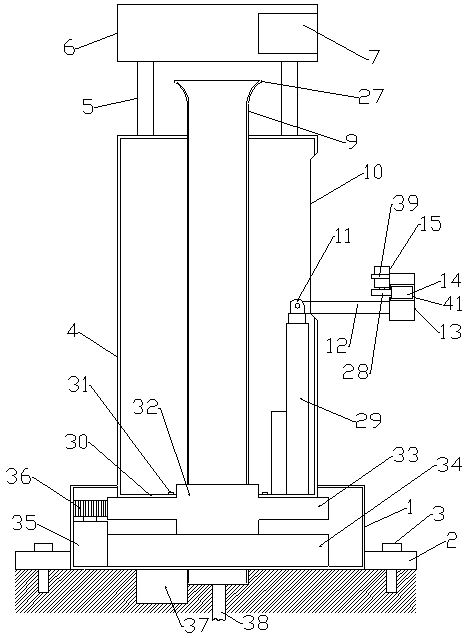

[0018] like figure 1 , 2 , As shown in 3 and 4, a robot intelligent refueling equipment includes a central fixed sleeve 9, the outer side of the bottom of the central fixed sleeve 9 is fixedly installed with a bottom stable support 34, and the center above the bottom stable support 34 The outer side of the fixed sleeve 9 is fitted with a rotary bearing 32, a rotary toothed disc 33 is fixedly installed on the circumferential direction of the rotary bearing 32, a bottom rotary motor 35 is fixedly installed on one side of the bottom stable support 34, and the output end of the bottom rotary motor 35 Fixedly connected with the bottom rotating gear 36, the rotating toothed disc 33 meshes with the bottom rotating gear 36, the rotating cylinder 4 is fixedly installed on the top of the rotating toothed disc 33, and the bottom outer side of the rotating cylinder 4 is fitted with a bottom protective shell 1. The top of the rotary cylinder 4 is provided with a limit hole, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com