Disk embroidery assembly mechanism of protection type high-precision computer disk embroidery machine

A general mechanism, high-precision technology, applied in the direction of the embroidery machine mechanism, embroidery machine, automatic control embroidery machine, etc., can solve the problem of damage to the service life of the movable blade b6, affecting the normal operation of other components, and small triangle space, etc. The structure is set ingeniously, the cost of updating and maintenance is saved, and the effect of failure is not easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

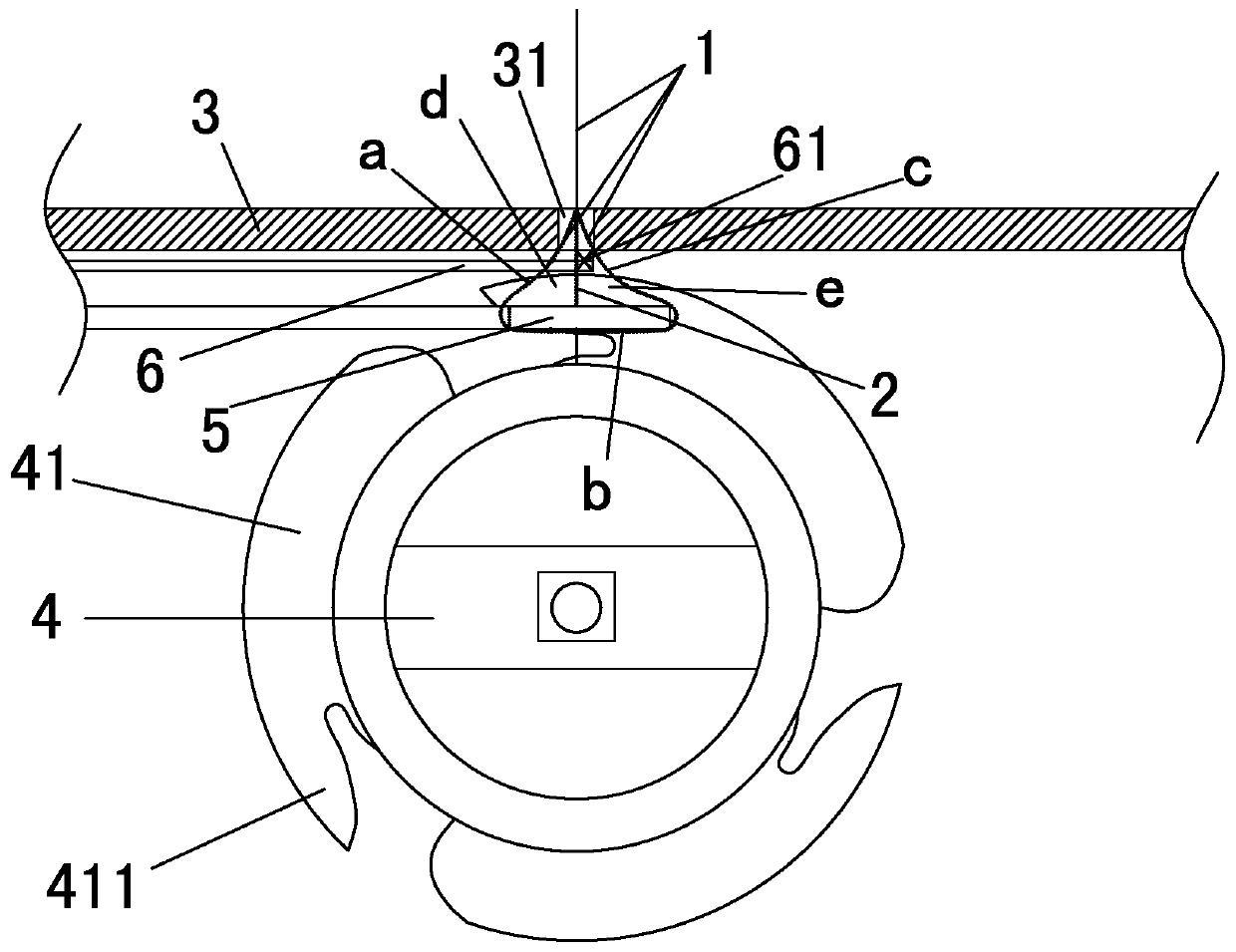

[0064] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

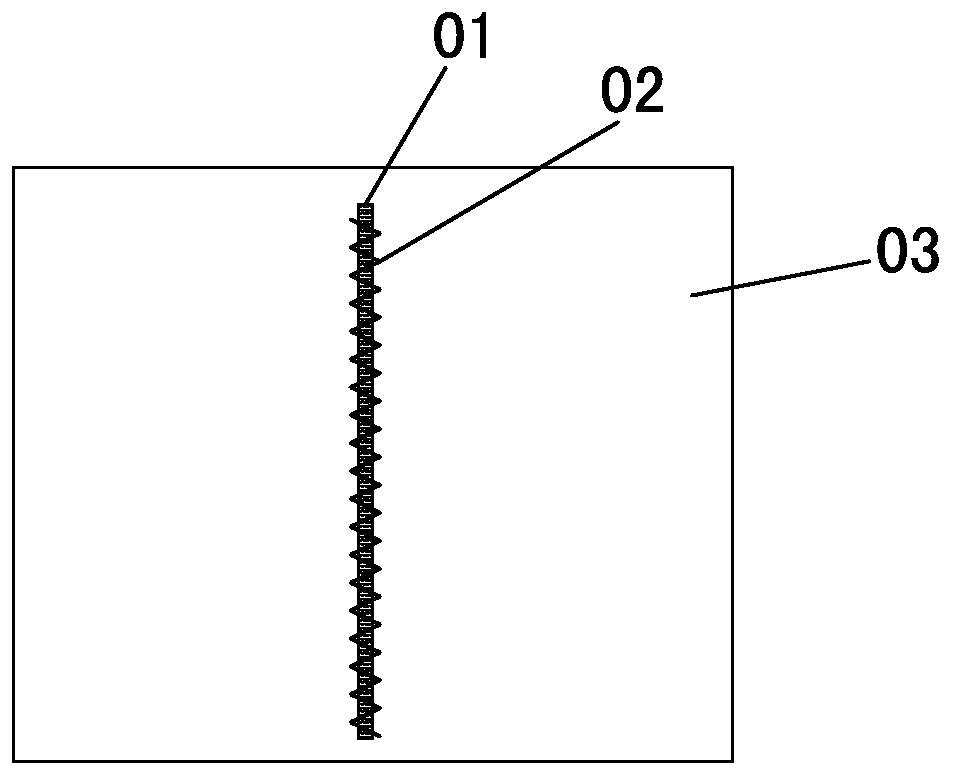

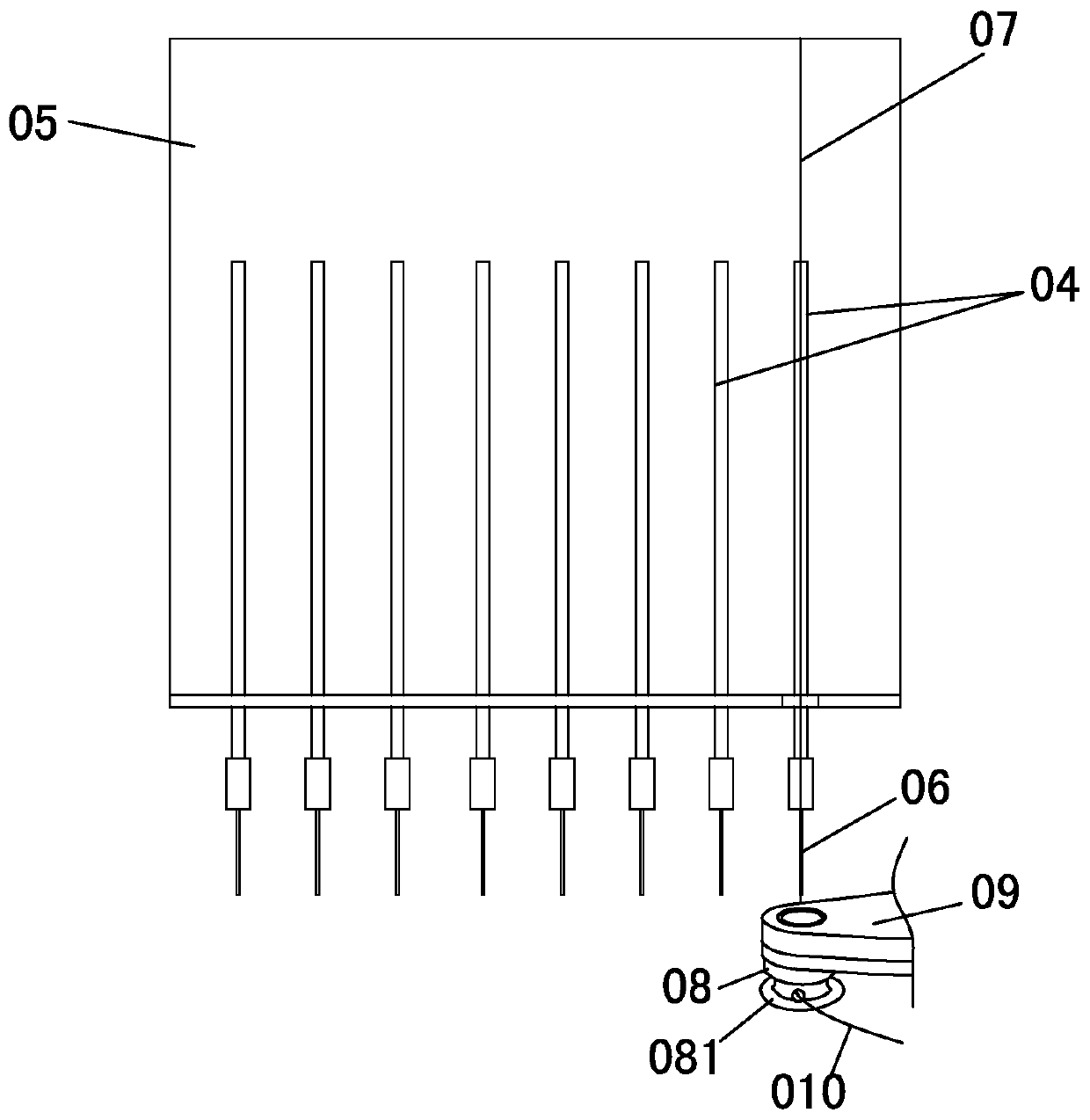

[0065] The overall coil embroidery mechanism of a protective high-precision computerized coil embroidery machine disclosed by the present invention includes an embroidery frame moving mechanism, a needle bar presser device arranged above the embroidery frame moving mechanism, and an embroidery frame arranged under the embroidery frame moving mechanism Bottom thread trimming mechanism, in this embodiment, there is a corresponding relationship between the three in the upper and lower positions. When the coil embroidery is working, they work synchronously. When not working, there may be no substantial structural connection between the three; the following is combined with the accompanying drawings Describe in detail the position connection relationship between each institution.

[0066] The needle bar presser foot d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com