Profiling mechanism of rice direct seeder

A profiling mechanism and live broadcast machine technology, applied in the field of agricultural machinery, can solve the problems of being unable to move forward and unable to adapt to the terrain of different fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

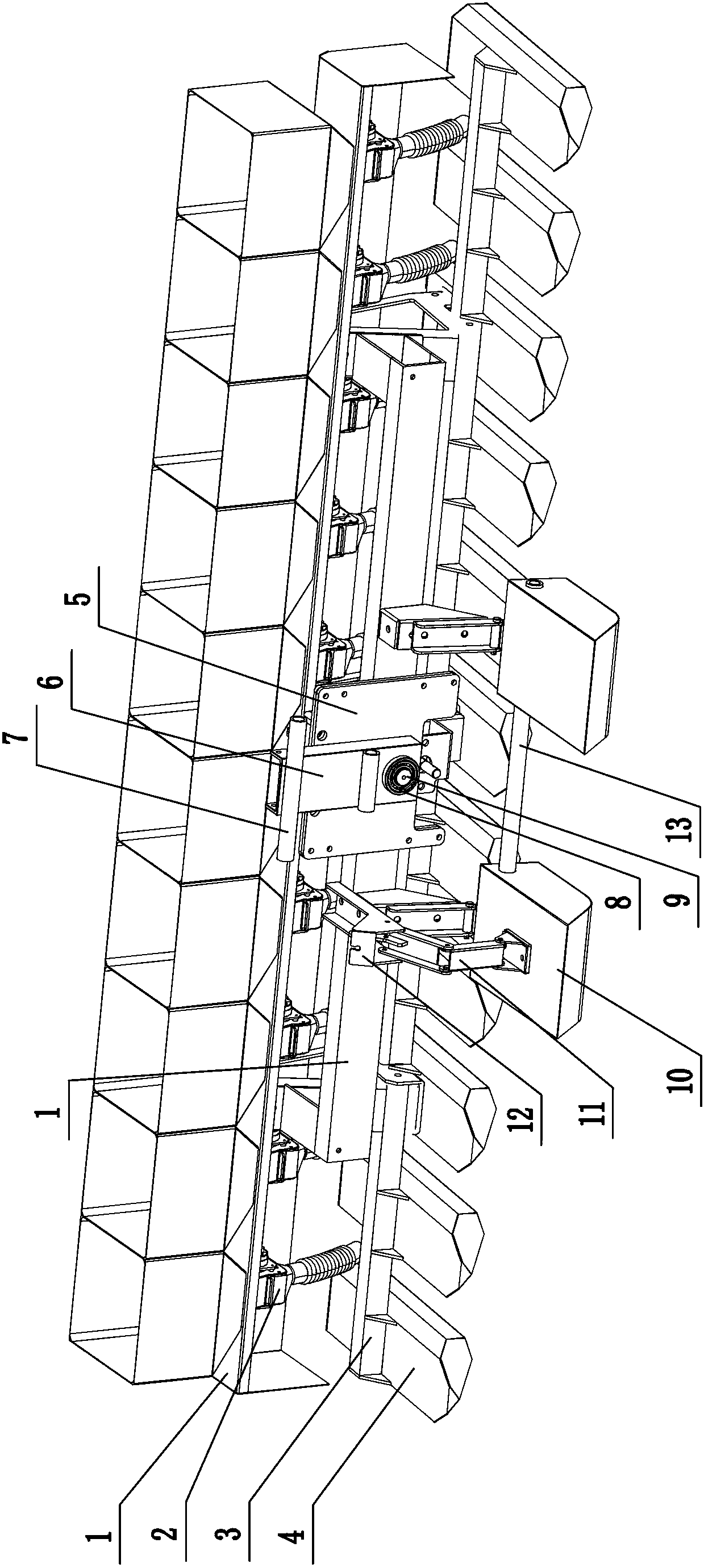

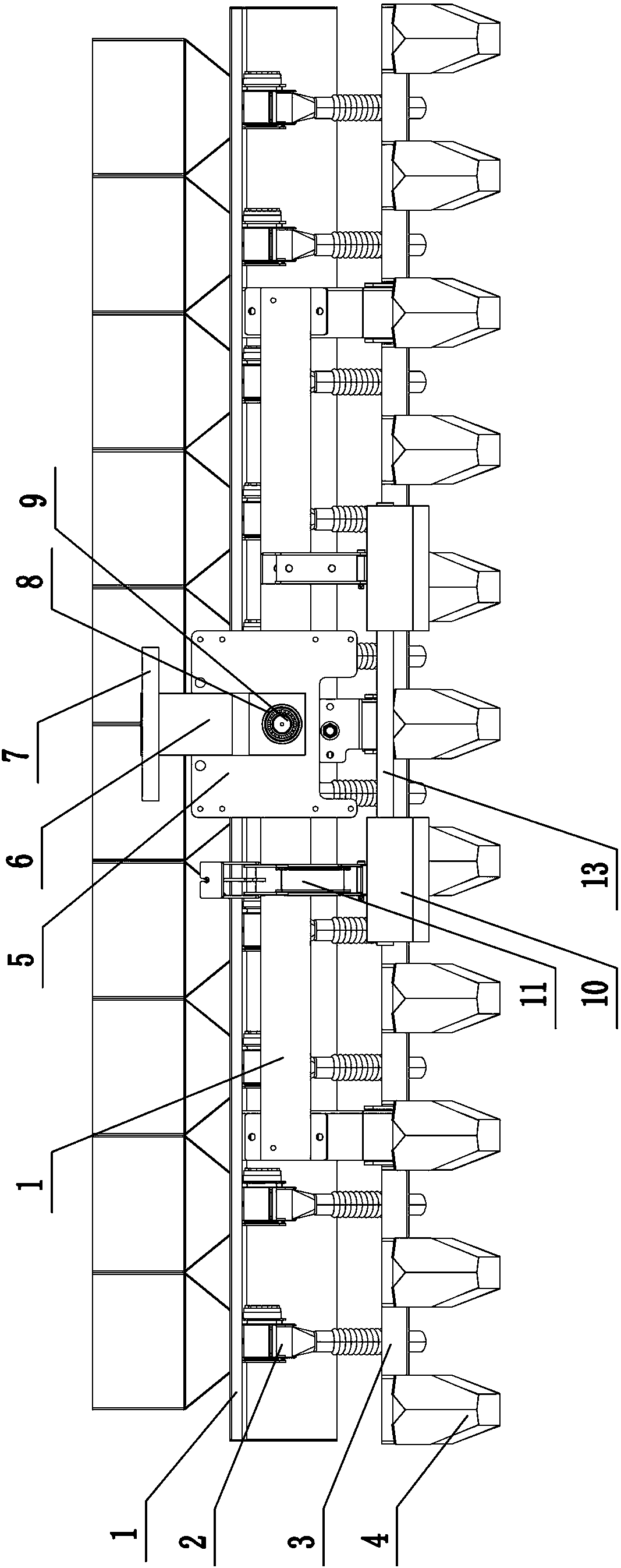

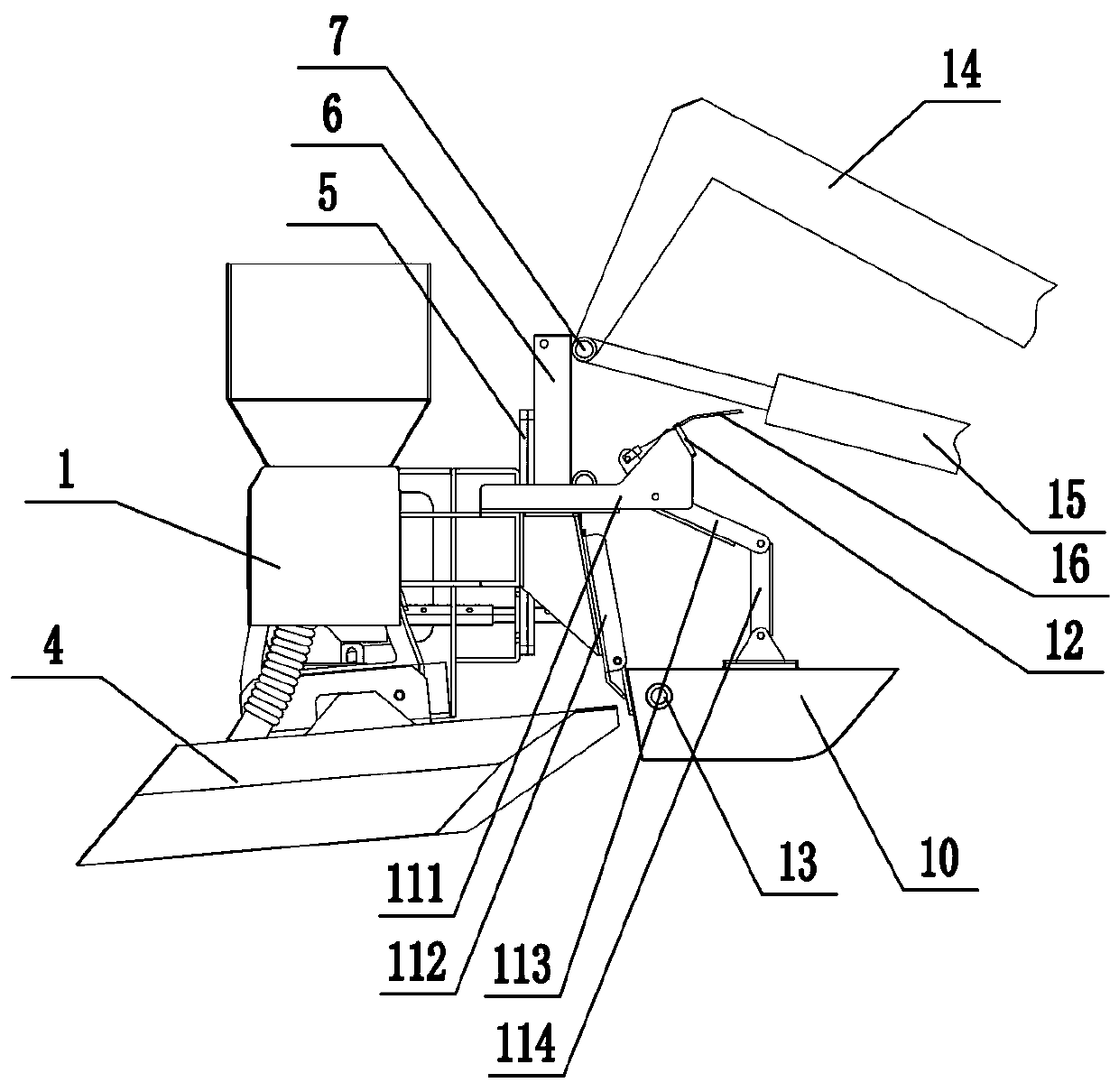

[0014] see Figure 1-3 , this embodiment includes a seed metering device bracket 1 installed at the tail of the rice direct seeding machine, several seed metering devices 2 are arranged side by side on the top of the seed metering device bracket 1, and a ditch opener connecting frame 3 is fixedly installed at the bottom of the seed metering device bracket 1 , a number of openers 4 are installed on the opener connecting frame 3 staggered with the seed meter 2, a support plate 5 is fixedly installed in the middle of the seed meter support 1, and a lifting frame 6 is installed at the front end of the support plate 5 , the lifting frame 6 is provided with a sleeve 7, the sleeve 7 is hinged with the lifting arm 14 positioned at the front end of the rice direct seeding machine, the sleeve 7 is also hinged with a piston rod of an oil cylinder 15, and the cylinder seat of the oil cylinder 15 is connected with the front end of the rice direct seeding machine The head is hinged; the see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com