Prestressed ejection type pile side grouting valve and grouting method thereof

An ejection-type, pre-stressed technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as inability to ensure grouting effect, grouting failure, and wear of the grouting valve on the side of the pile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

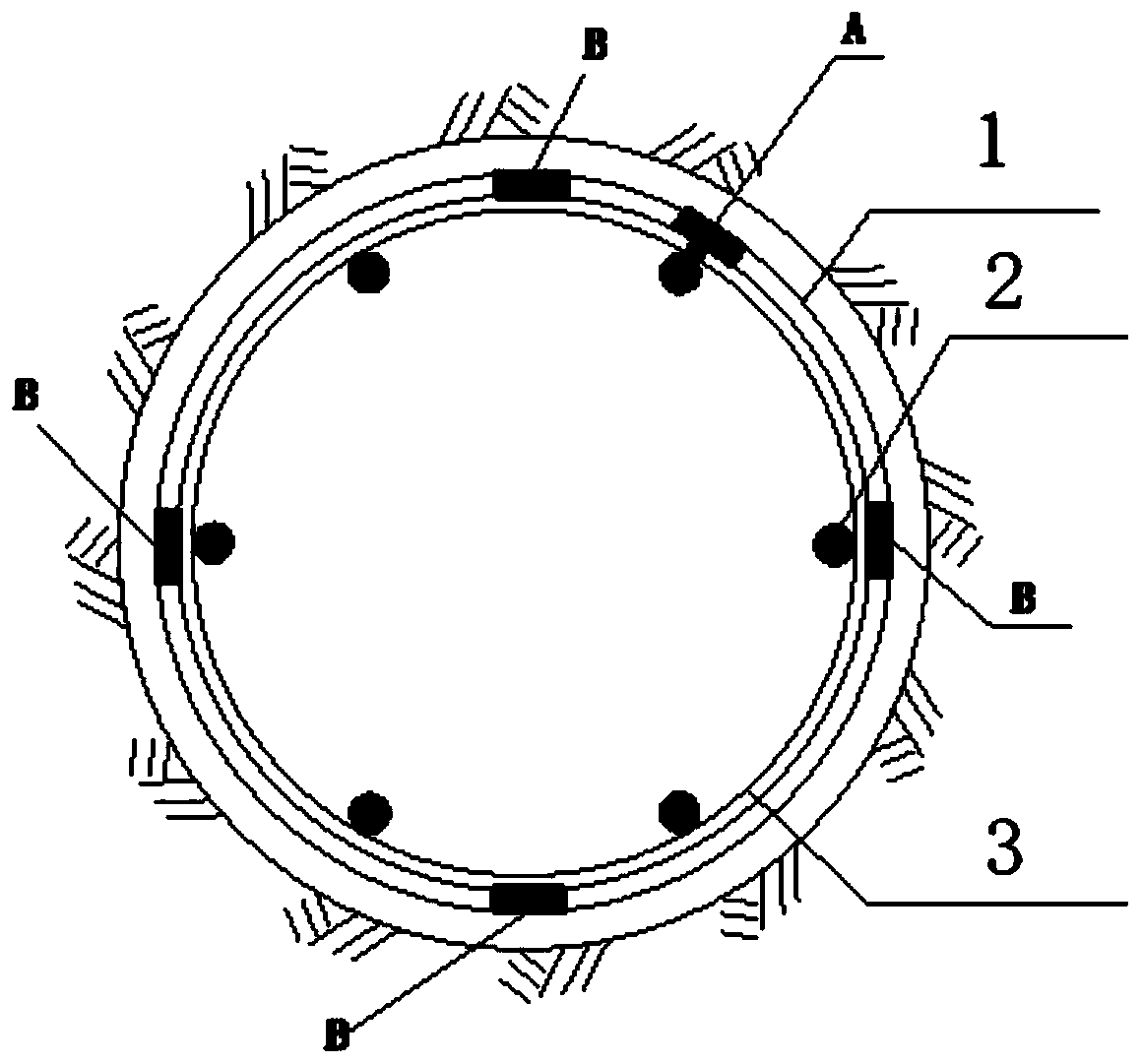

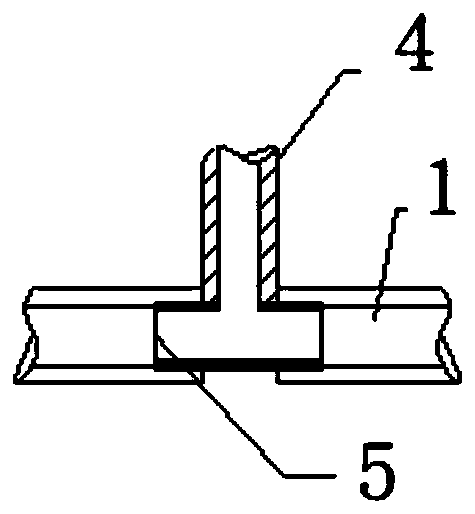

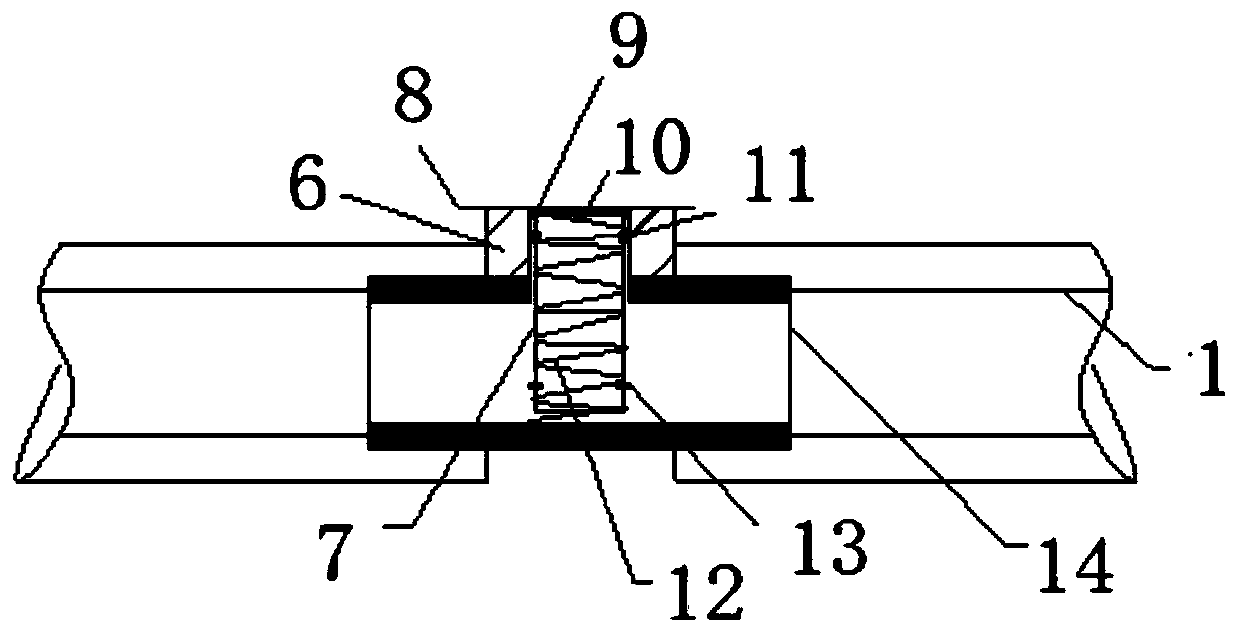

[0023] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

[0024] Such as image 3 As shown, a prestressed ejection type pile side grouting valve, including a grouting valve outer cylinder 6 and a grouting valve inner cylinder 7, sliding and telescopic between the grouting valve outer cylinder 6 and the grouting valve inner cylinder 7, and setting The limit block 13 is used as a one-way check mechanism; the sealing and water-stop rubber ring 11 is set between the outer cylinder 6 of the grouting valve and the inner cylinder 7 of the grouting valve, and the bottom of the inner cylinder 7 of the grouting valve is provided with a grout hole 10, the escape hole 10 is outsourced with a waterproof rubber film 9;

[0025] A spring 12 is set between the grouting valve outer cylinder 6 and the grouting valve inner cylinder 7, and the grouting valve inner cylinder 7 protrudes from the grouting valve outer cylinder 6 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com