AGV with clamping and holding mechanism and butt joint method thereof

A technology for docking components and clamping arms, which is used in traction connectors, transportation and packaging, vehicle components, etc., which can solve the problem of increasing the uncertainty of the feeder, the inability to guarantee the stopping accuracy, and increasing the difficulty of docking the feeder with the next station, etc. problems, to achieve the effect of improving driving accuracy and stopping accuracy, preventing left and right swing, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

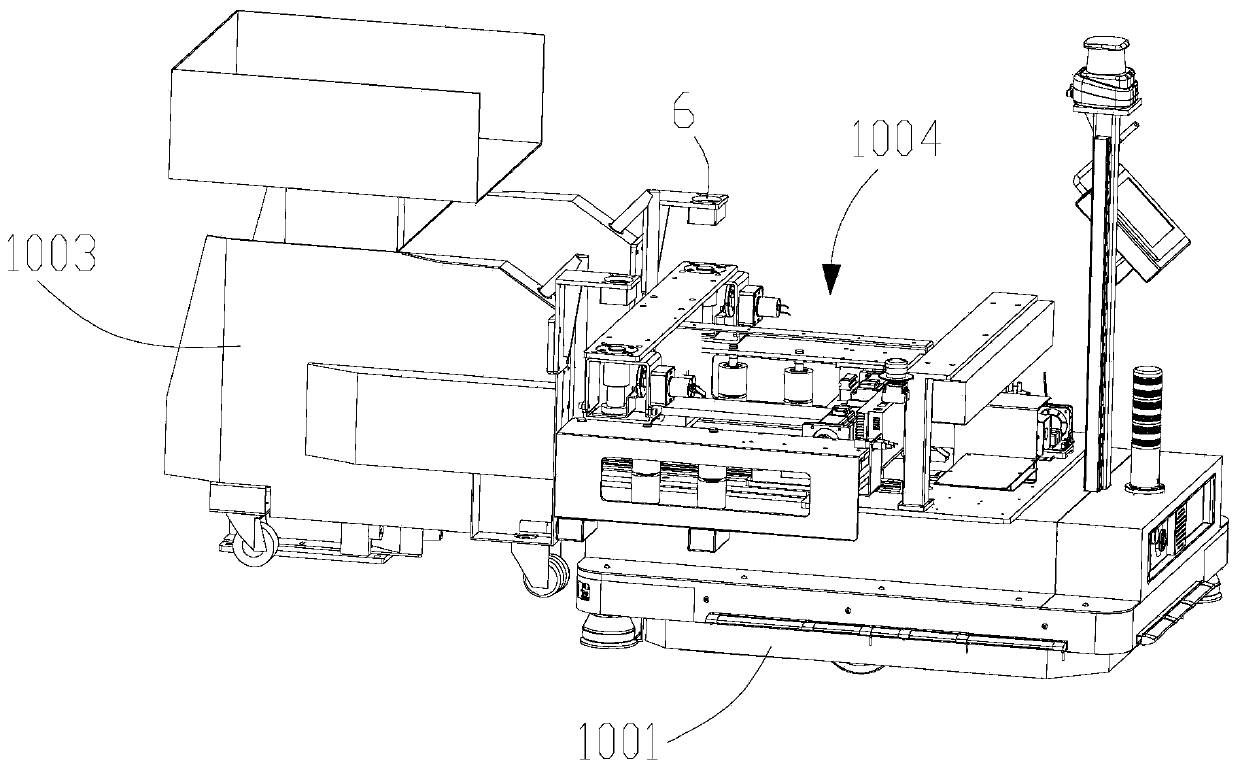

[0033] see Figure 1 to Figure 10 , an AGV with a clamping mechanism, which includes an AGV body 1001, a docking assembly 1002, and a clamping mechanism 1004, the docking assembly 1002 is used to dock with the docking mechanism on the material cart 1003, and the clamping mechanism 1004 is arranged on On the AGV body 1001, the clamping mechanism 1004 includes a telescopic assembly 2 and two sets of clamping arm assemblies 1, the telescopic assembly 2 is arranged on the AGV body 1001, and the clamping arm assembly 1 is arranged on the telescopic assembly 2 Above, when the AGV docks with the material truck 1003, the two sets of clamp arm assemblies 1 protrude to both sides of the material vehicle 1003 along with the telescopic assembly 2, and are used to limit the left and right directions of the material vehicle 1003. Swing range; wherein, the clamping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com