Combustion device

A combustion device and combustion chamber technology, which is applied to burners, combustion types, combustion methods, etc., can solve the problems of poor combustion state and increase of carbon monoxide concentration in combustion exhaust gas, maintain combustion performance, and inhibit the increase of carbon monoxide concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

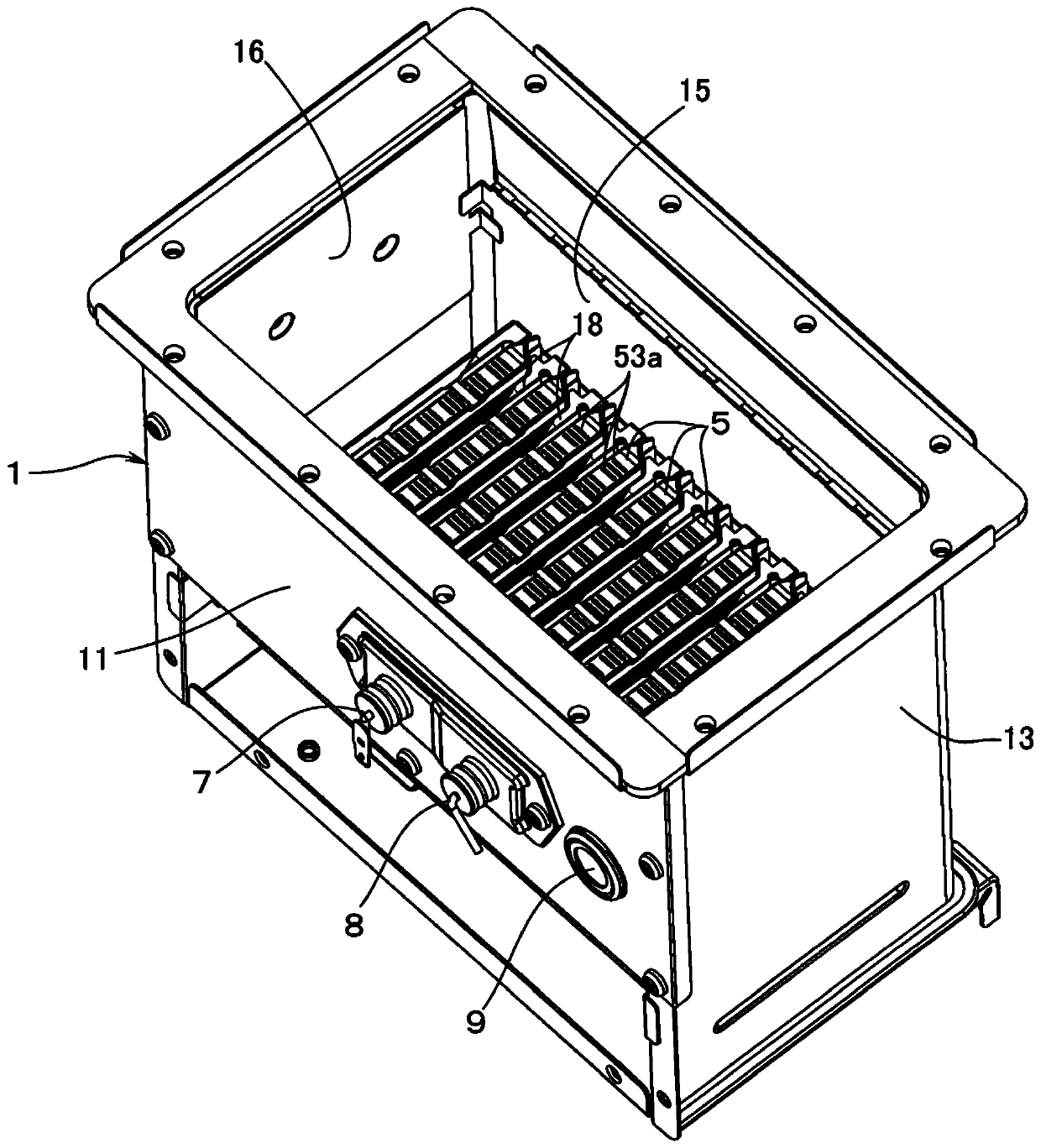

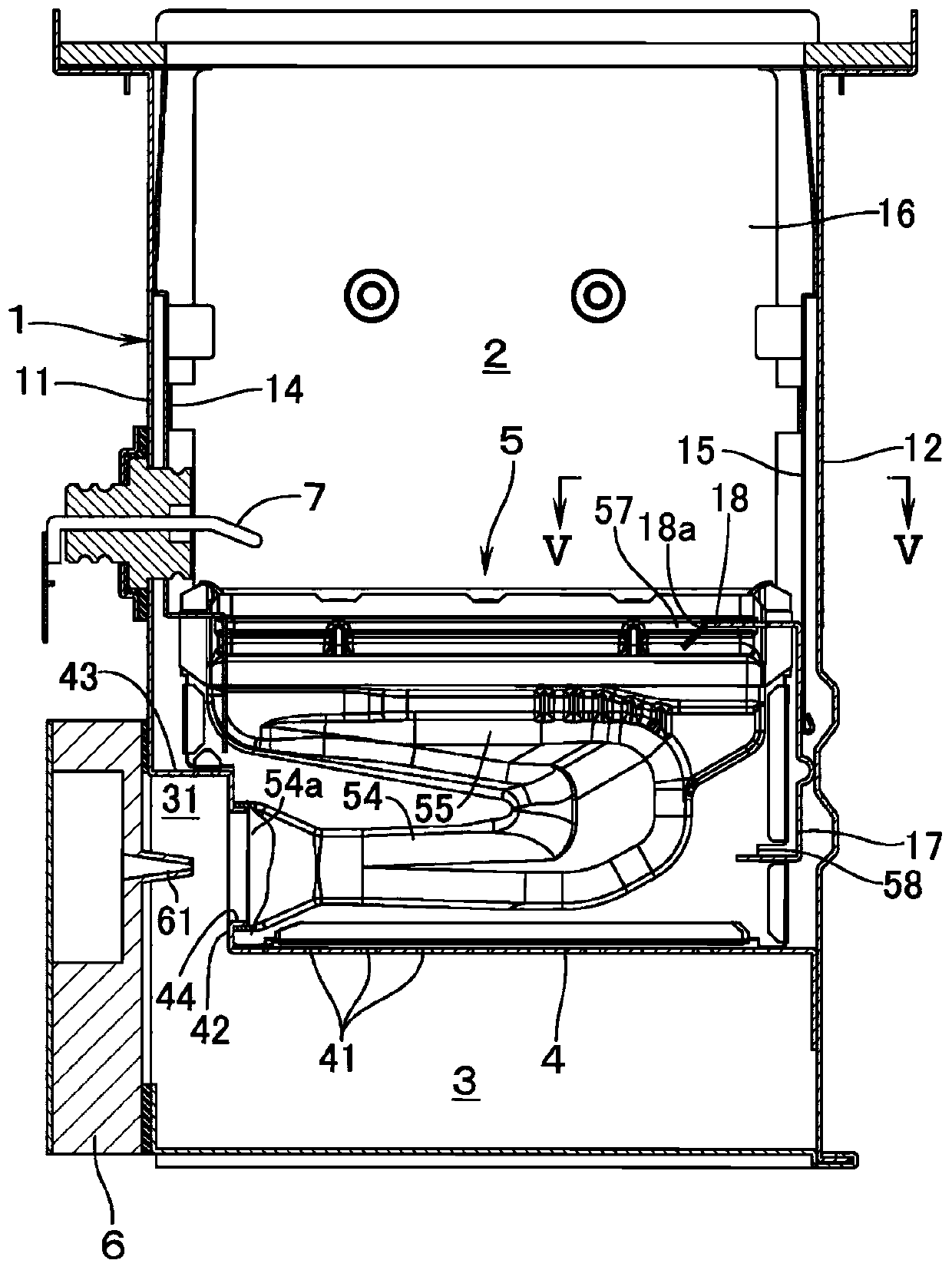

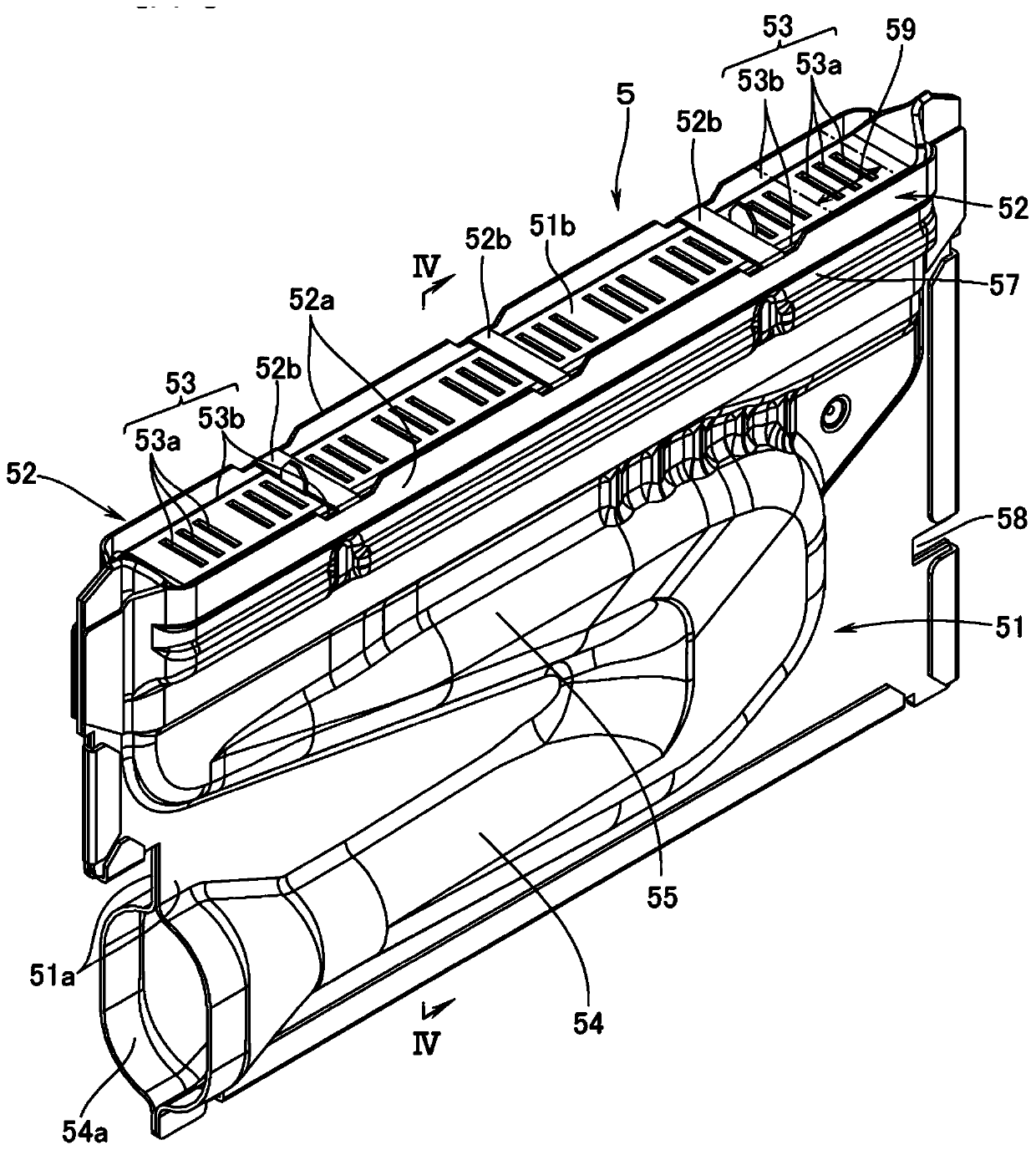

[0020] refer to figure 1 , figure 2 , 1 denotes a combustion case constituting a combustion device including a heat source machine for hot water supply. The upper surface of the combustion case 1 is open, and a heat exchanger for supplying hot water (not shown) as an object to be heated is provided above the combustion case 1 . In the combustion housing 1, a combustion chamber 2 and an air supply chamber 3 on the lower side of the combustion chamber 2 are arranged. The air supply chamber 3 is separated from the combustion chamber 2 by a partition plate 4 . In the combustion chamber 2, a plurality of burners 5 long in the front-rear direction are arranged side by side with a gap in the lateral direction.

[0021] A combustion fan (not shown) is connected to the bottom surface of the air supply chamber 3 , and air is supplied to the air supply chamber 3 from the combustion fan. A plurality of distribution holes 41 are formed in the partition plate 4 . And the air supplied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com