Automatic fuzzy ball removing equipment and fuzzy ball recognition method

A hair ball and equipment technology, applied in textiles and papermaking, fabric surface trimming, textile material inspection, etc., can solve the problems of manpower consumption and complicated operation, and achieve the effect of not being easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

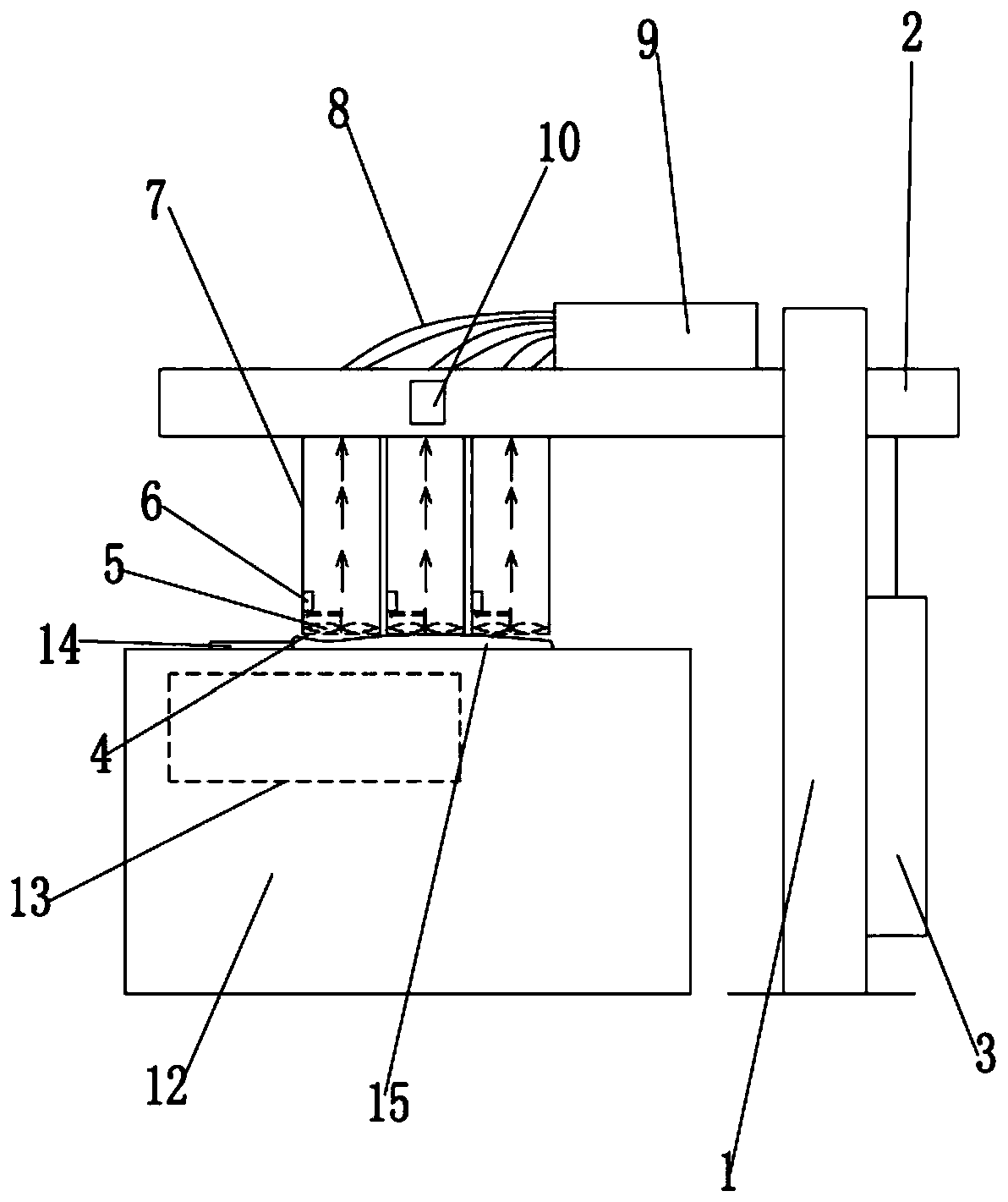

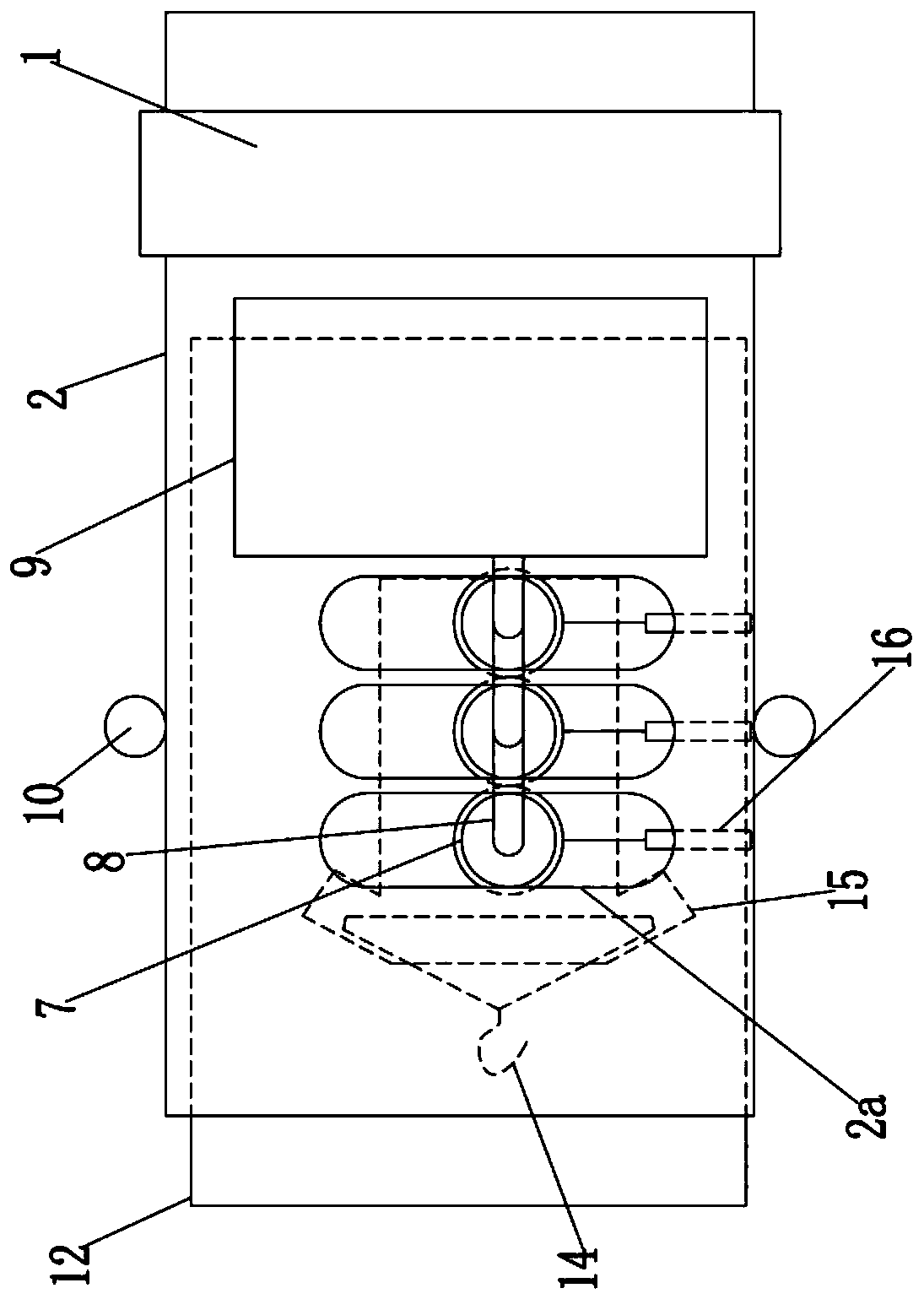

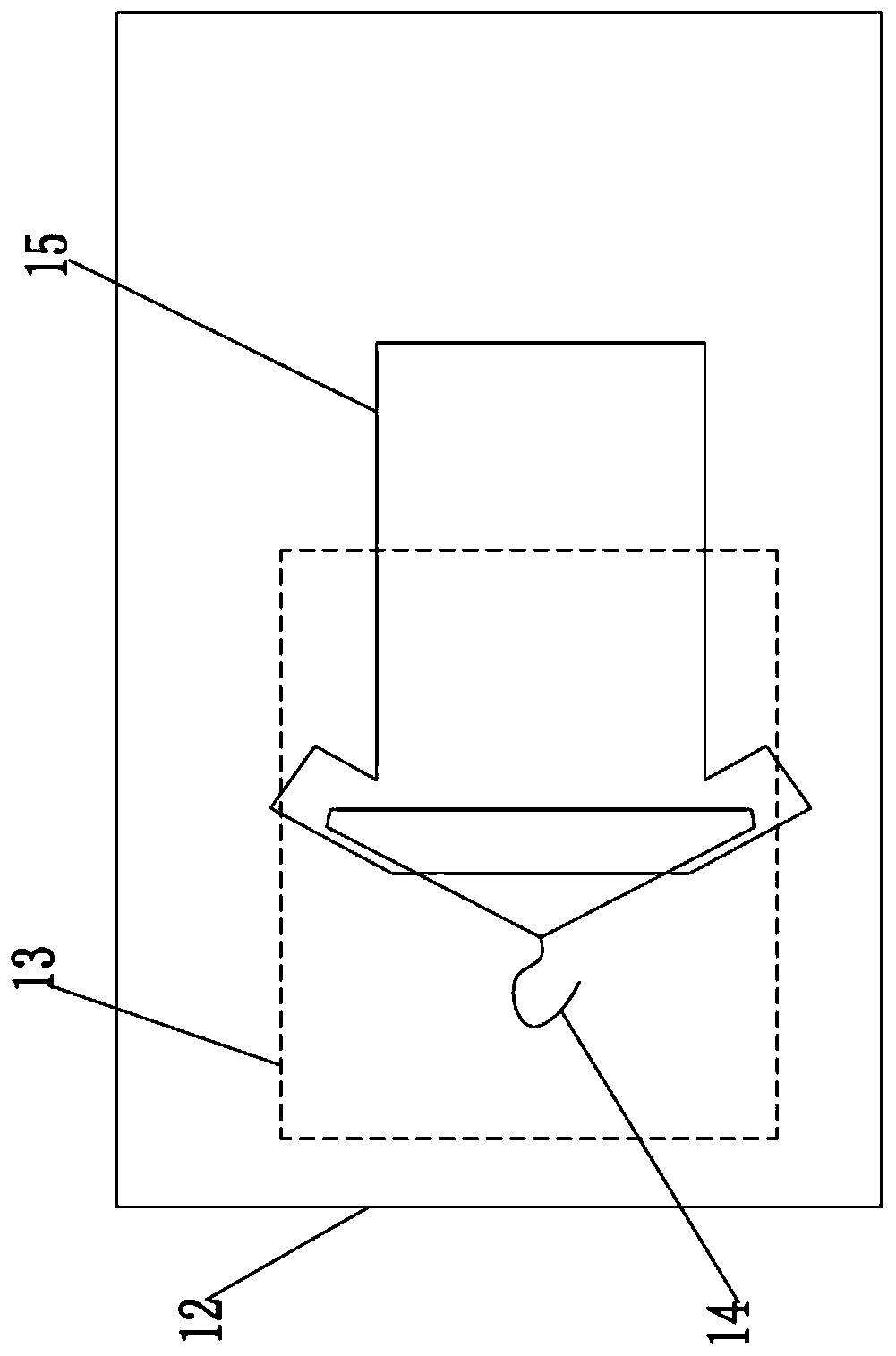

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0039] combine Figure 1-4 As shown, an automatic hair removal equipment, including:

[0040] The stage 12, the upper side is a plane structure and is used for laying clothes 15;

[0041] a locking assembly provided on the carrier 12 for securing the garment 15 on the carrier 12; and

[0042] A hairball removal mechanism for removing hairballs from clothing 15 .

[0043] Among them, the hairball removal mechanism includes:

[0044] main seat 1;

[0045] The lifting seat 2 that is mounted on the main seat 1 in a lifting and sliding manner and is directly above the clothes 15;

[0046] The lift electric push rod 3 installed on the main base 1, the telescopic rod of the lift electric push rod 3 is connected with the lift base 2; and

[0047] A recovery box 9 for recovering hair balls is detachably mounted on the lifting base 2 .

[0048] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com