Rotary retractable claw-type raft frame seedling rope harvesting and transferring device and system

A technology of transfer device and telescopic teeth, which is applied in the directions of transportation and packaging, harvesters, applications, etc., can solve the problems of low degree of mechanization, lack of technical equipment, low degree of mechanization, etc., and achieve easy promotion and application, and high efficiency of rope harvesting , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

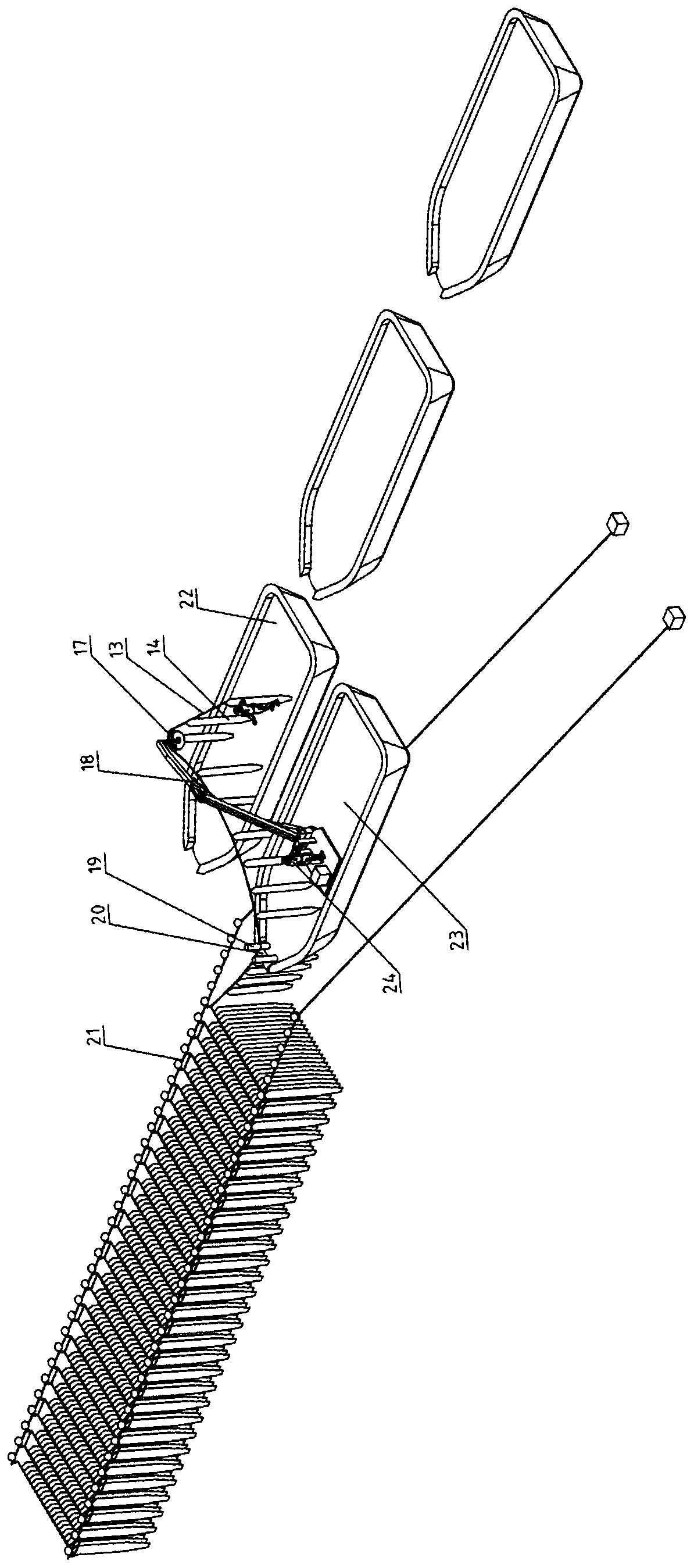

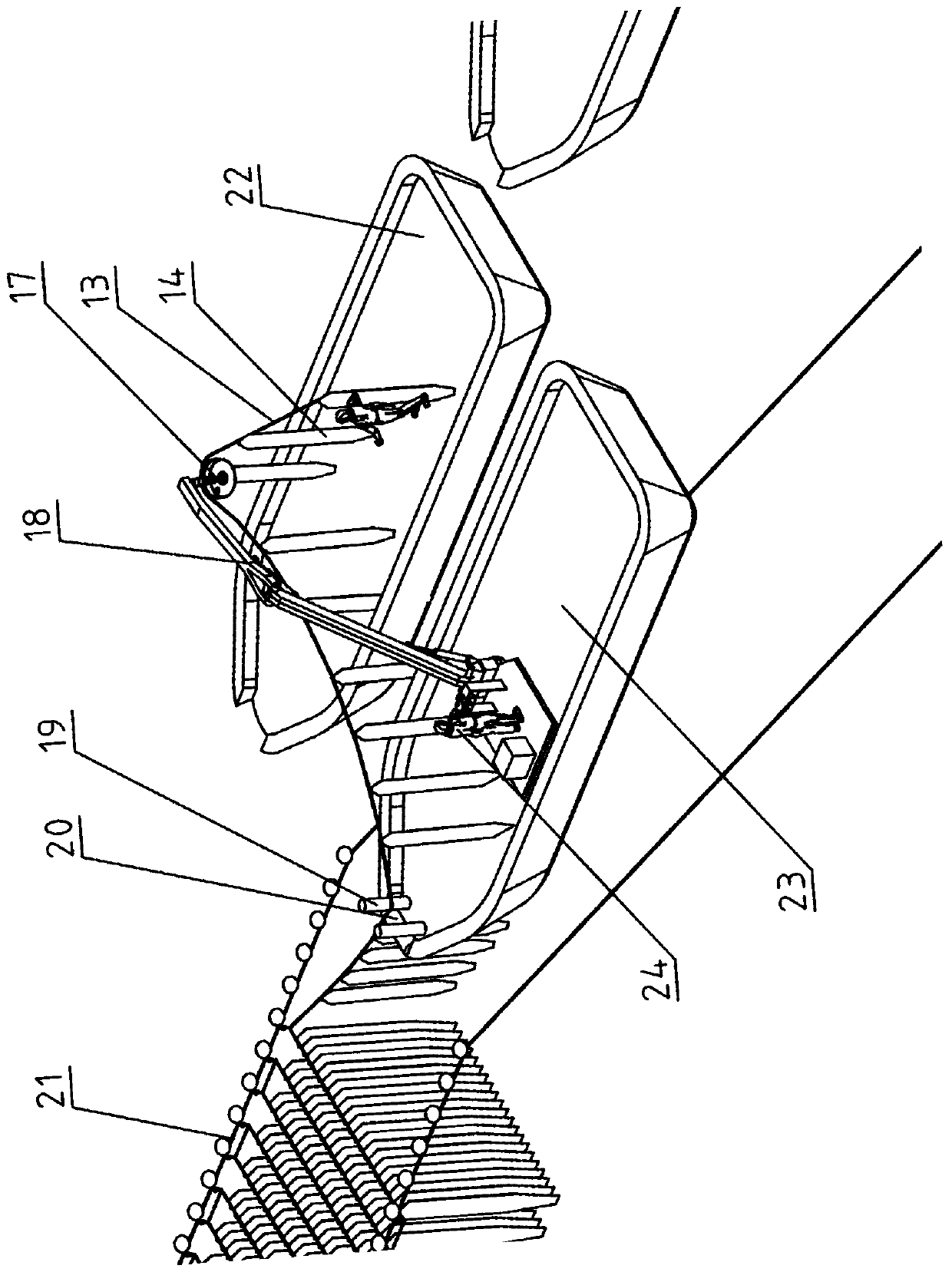

[0031] see figure 1 , a rotary telescopic tooth claw type raft frame seedling rope harvesting and transporting system, comprising a rotary telescopic tooth claw type raft frame seedling rope harvesting and transporting device 17, a rotary folding arm crane 18, kelp seedling rope (grown rope) 13, Kelp 14, raft frame 21, horizontal guide drum 20, vertical guide drum 19, harvesting ship 23, transport ship 22, operator 24. Wherein the tandem connection mode of the raft frame seedling rope (grown rope) can refer to the Chinese patent document whose publication date is February 2, 2018 and whose document number is CN107651461A.

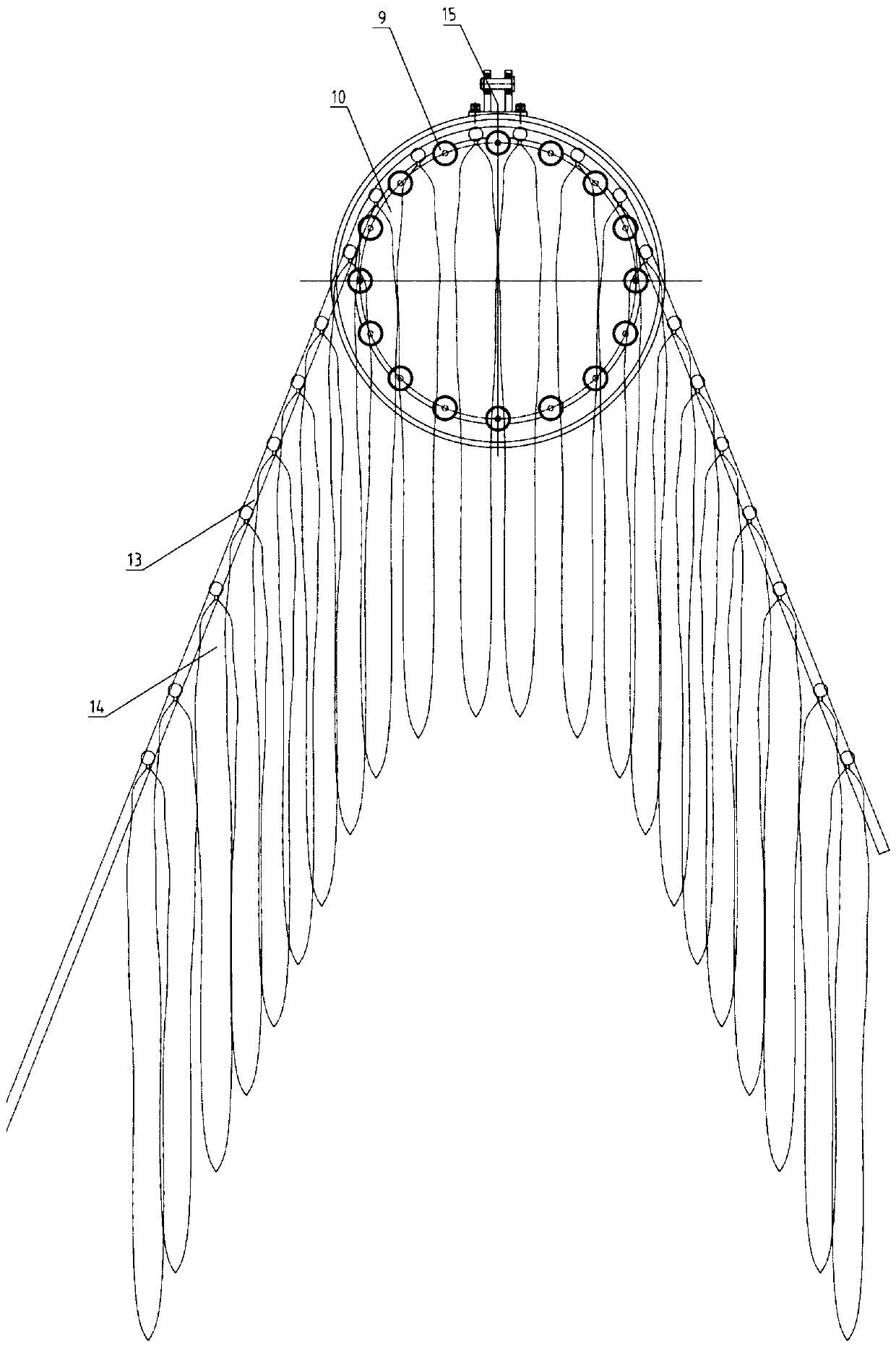

[0032] see Figure 3 to Figure 7 , a rotary retractable tooth claw type raft rope harvesting and transporting device, including a rotary drive device 1, a rotating shaft 2, a rotary disk 3, an end cam or a sheave 4, a swing rod 5, a support 6, and a retractable claw 7 , claw seat 8, block 9, cover 10, frame 11, roller 12, kelp seedling rope (growing rope)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com