Cap feeding tray for cylindrical lithium ion battery production

A lithium-ion battery and cylindrical technology, which is applied in the field of cap feeding trays for the production of cylindrical lithium-ion batteries, can solve the problems of messy caps, the inability to achieve accurate coverage of cylindrical lithium-ion batteries, and reduce processing efficiency, so as to improve processing Efficiency, improved sealing protection, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

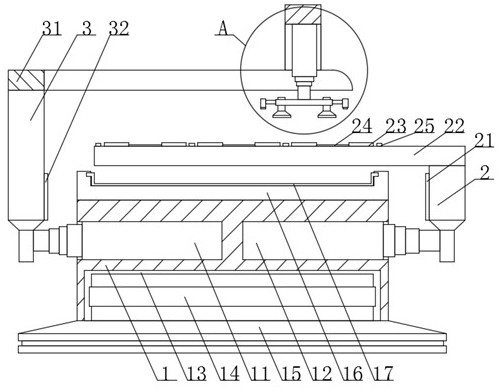

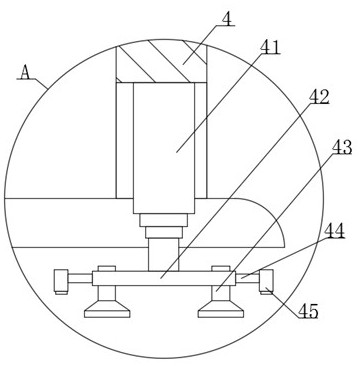

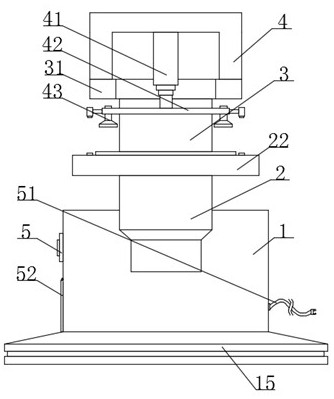

[0027] see Figure 1-5, the present invention provides a technical solution: a cap feeding tray for cylindrical lithium-ion battery production, comprising a fixed seat 1, a first support frame 2, and a second support frame 3, and the fixed seat 1 also includes a base 15 , the lower surface of the fixing seat 1 is fixedly connected with a base 15 by bolts, the base 15 is in the shape of a quadrangular pyramid, the base 15 is used as a supporting and fixing device for the fixing seat 1, and the middle part of the outer periphery of the base 15 is provided There is a concave arc, and the concave arc provided on the periphery of the base 15 can provide an effective focus point when adjusting the azimuth angle of the fixing base 1 through the base 15 and thus facilitate the user to adjust. The front middle of the fixing base 1 is fixedly connected by bolts There is a controller 5, the controller model is SPD-070-AVT controller, which is convenient for users to scribe the first elec...

Embodiment 2

[0029] see Figure 3-7 , the present invention provides a technical solution: a cap feeding tray for cylindrical lithium-ion battery production, comprising a fixed seat 1, a first support frame 2, and a second support frame 3, and the fixed seat 1 also includes a base 15 , the lower surface of the fixing seat 1 is fixedly connected with a base 15 by bolts, the base 15 is in the shape of a quadrangular pyramid, the base 15 is used as a supporting and fixing device for the fixing seat 1, and the middle part of the outer periphery of the base 15 is provided There is a concave arc, and the concave arc provided on the periphery of the base 15 can provide an effective focus point when adjusting the azimuth angle of the fixing base 1 through the base 15 and thus facilitate the user to adjust. The front middle of the fixing base 1 is fixedly connected by bolts There is a controller 5, the controller model is SPD-070-AVT controller, which is convenient for users to scribe the first ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com