Garbage can garbage bag hot melting device

A hot-melt device and garbage bag technology, which is applied in the field of sanitary appliances, can solve problems such as complex structure, poor sealing reliability and stability, and unpleasant odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

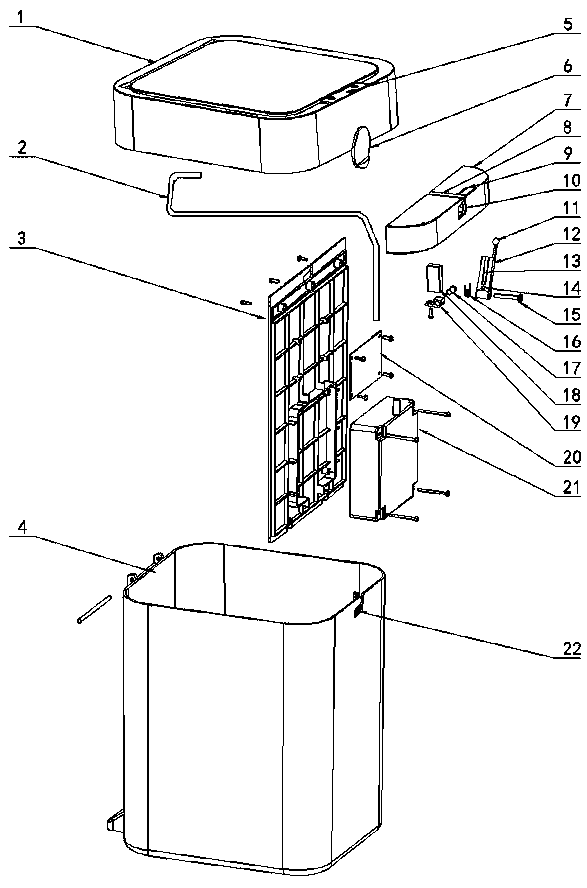

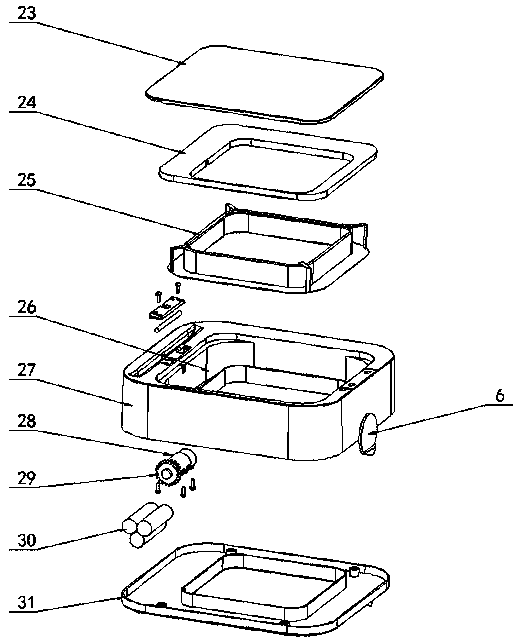

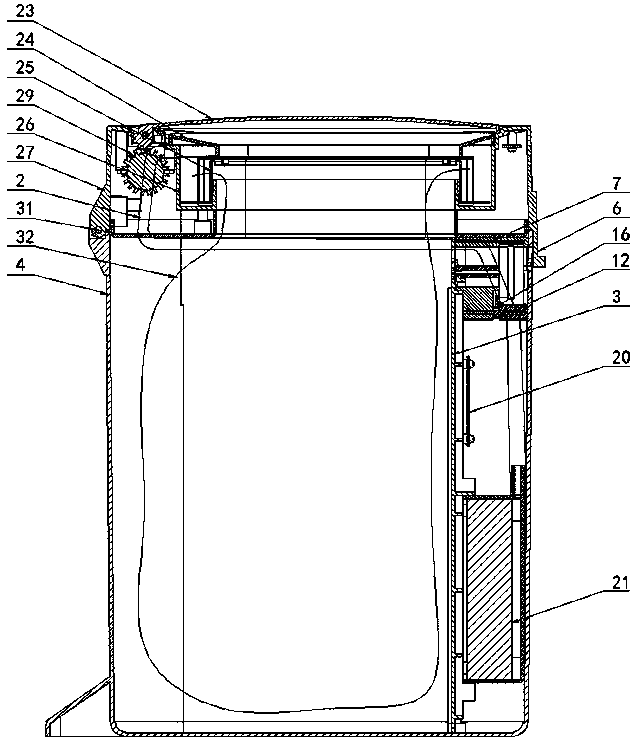

[0017] Figure 1 to Figure 7 As shown, the present invention creates a specific embodiment of a garbage can garbage bag thermal melting device, which is correspondingly installed on the opening side of the barrel body 4 and the barrel cover 1, and includes a sealing device seat fixed on the barrel body 4 partition 3 7. Sealing platen 12, hot-melt seat 18, touch switch 17, corresponding garbage bag card slot 8 on the sealing device seat 8 and handle chute 9 perpendicular to garbage bag card slot 8, hot-melt seat 18 and touch switch 17 correspond Installed on the sealing device seat 7 on one side of the garbage bag slot 8, the sealing pressure plate 12 is fixed with a handle 11 and hinged elastically on the other side of the garbage bag slot 8 through the torsion spring 16 and the hinge pin 15. On the seat 7, the handle 11 is slidably arranged on the handle chute 9, the sealing pressing plate 12 and the hot-melt seat 18 are correspondingly provided with an electric heating eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com