Fire-receiving basin convenient to adjust and used for steel structure welding

A brazier and steel structure technology, which is applied in the field of braziers and welding braziers, can solve the problems of inconvenient adjustment and large limitations of braziers, and achieve the effects of convenient adjustment, convenient hanging installation, and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

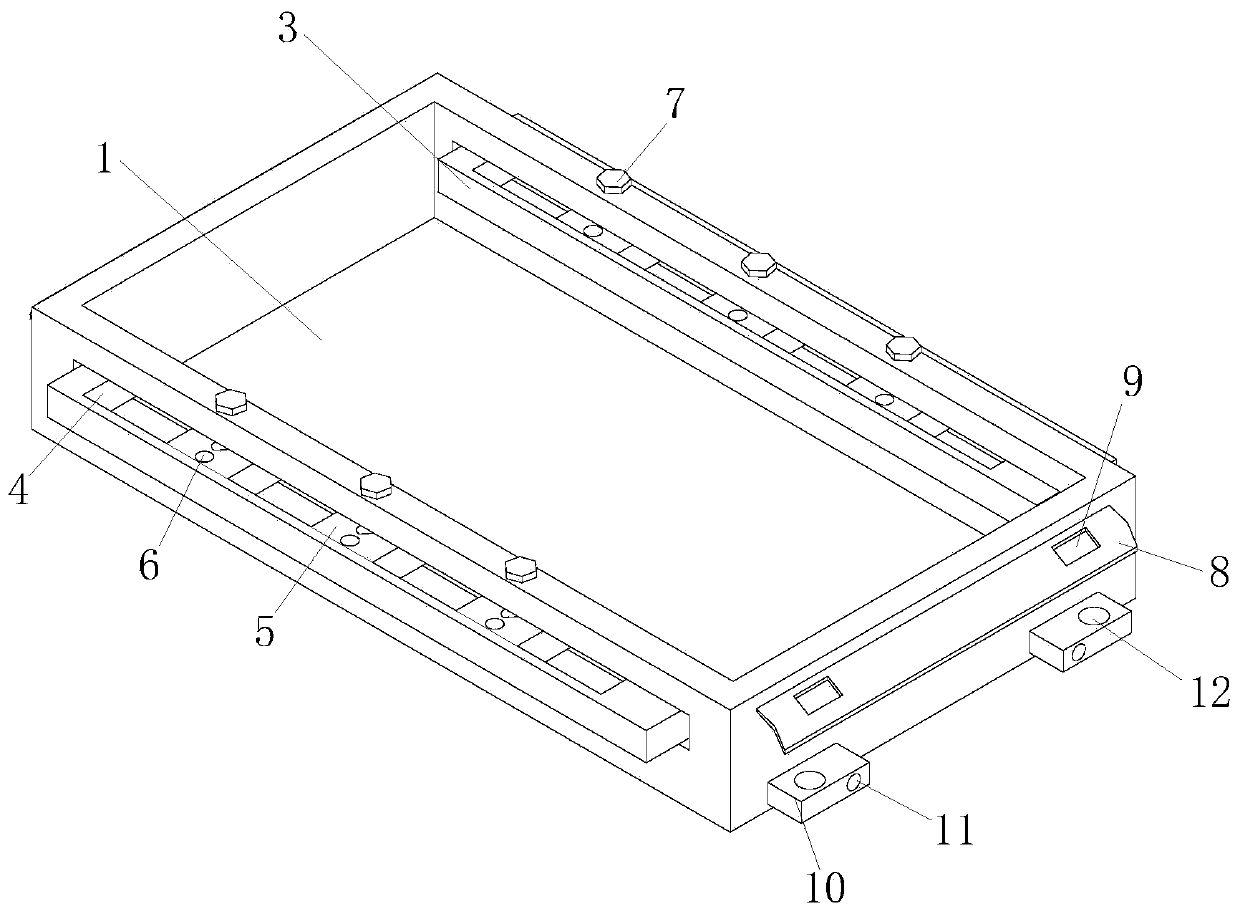

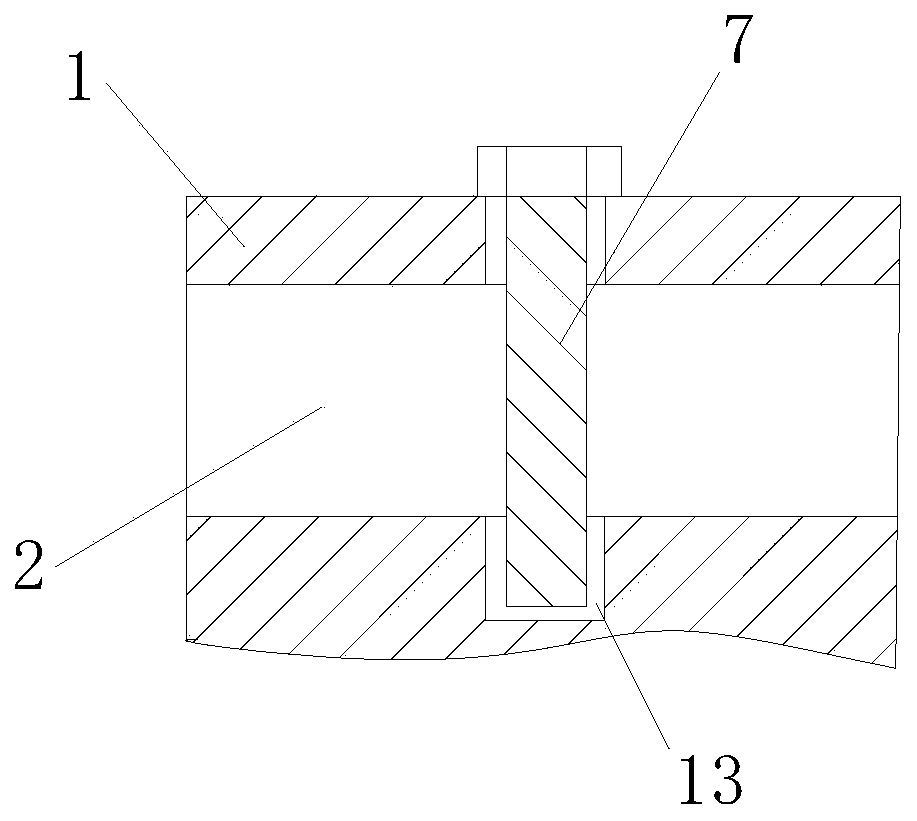

[0017] refer to Figure 1-2 , a brazier that is easy to adjust for steel structure welding, including a brazier body 1, the brazier body 1 is specifically a rectangular basin body, which is convenient for receiving welding slag and sparks, and both sides of the brazier body 1 are provided with chute 2 , a moving plate 3 is installed inside the chute 2, and the top of the moving plate 3 is provided with a card slot 4 along the length direction. It is integrally formed to improve the structural strength of the mobile plate 3. The connecting column 5 is evenly penetrated with a number of adjustment holes 6 along the length direction, and a number of adjustment bolts 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com