Material performance testing system under fixed multi-field coupling action in supergravity environment

A material performance and testing system technology, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc., can solve problems such as reducing blade fatigue life, achieve short experiment preparation period, and safe and reliable testing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with drawings and embodiments.

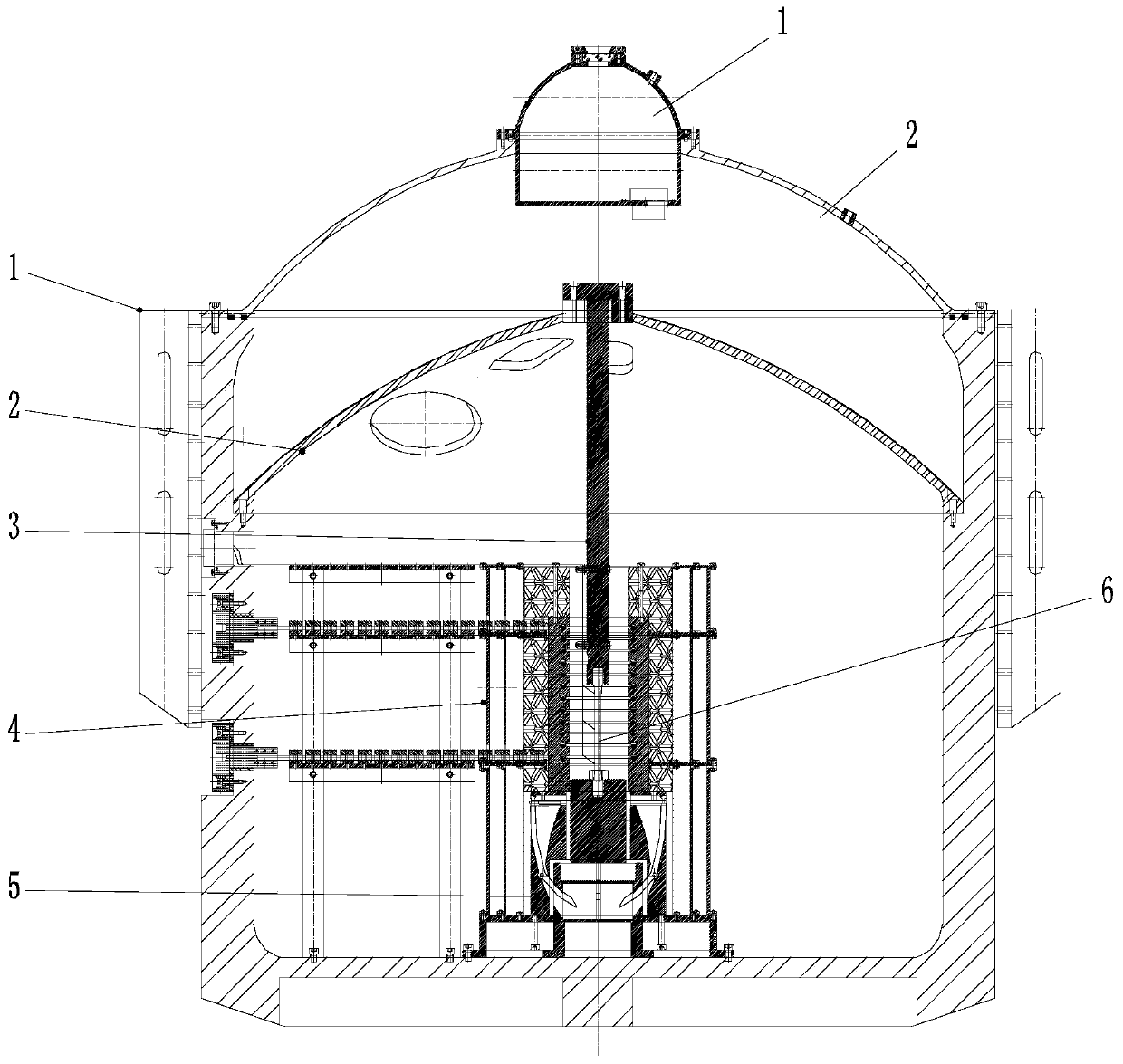

[0044] Such as figure 1 As shown, the specific implementation system includes a hoisting airtight cabin 1, a load-bearing frame 2, a high-temperature furnace 3, a mechanical testing device 4, and a buffer device 5; The frame 2 is covered on the high-temperature furnace 3, the buffer device 5 is installed at the bottom of the high-temperature furnace 3, the upper and lower ends of the mechanical test device 4 are connected to the top of the load-bearing frame 2 and the bottom of the high-temperature furnace 3, and the sample 6 is connected and installed in the mechanical test Device 4 ends.

[0045] The specific implementation system is as follows:

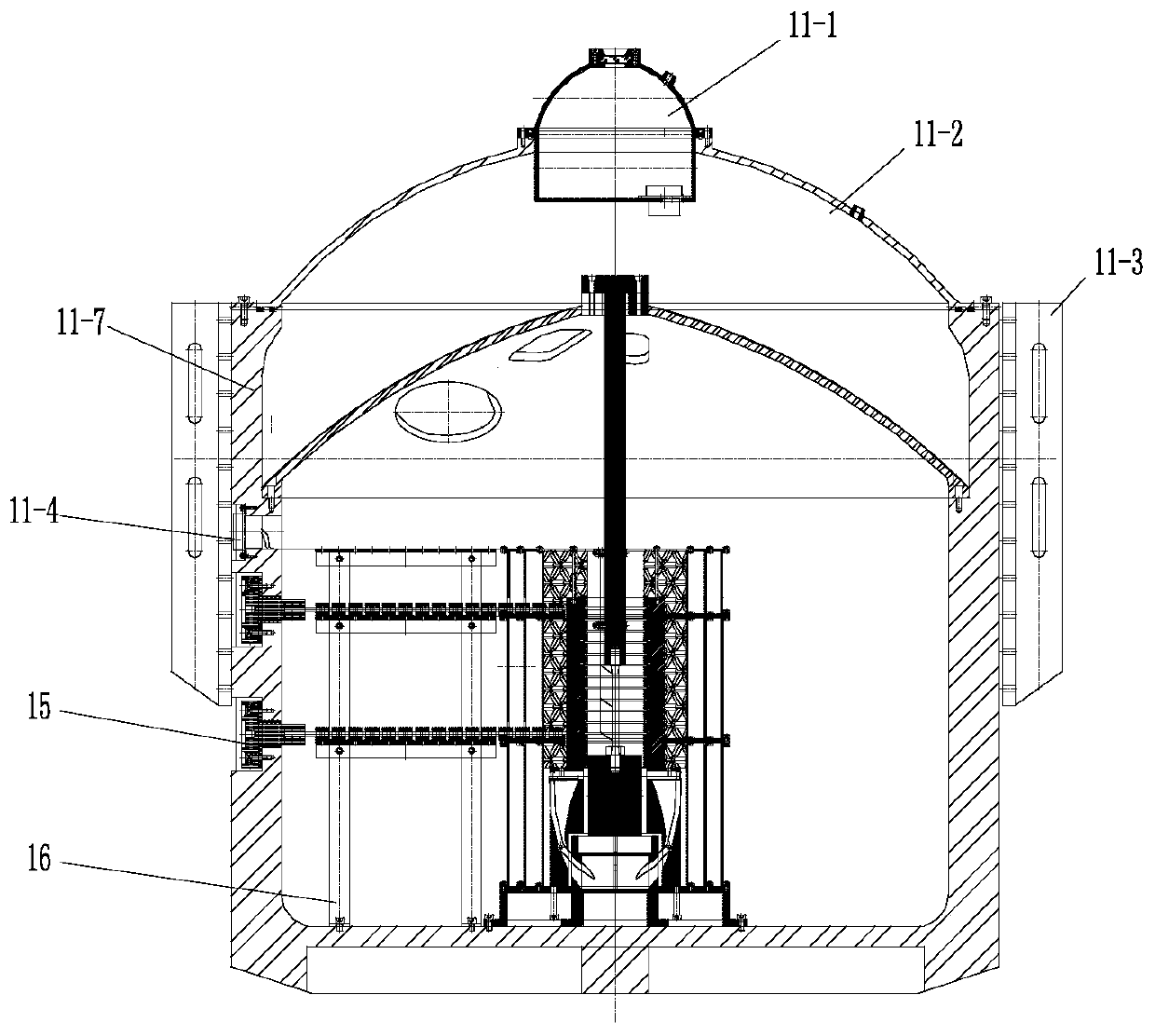

[0046] The hoisting airtight cabin 1 provides a sealed carrier for the body force-surface force-temperature coupling environment. Such as figure 2 As shown, the hoisting sealing cabin 1 comprises an upper sealing dome ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com