Steering wheel framework assembly welding jig

A welding fixture and steering wheel technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large welding fixture size, affecting production efficiency, affecting welding quality, etc., and achieves simple and fast installation speed Fast and effective in improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

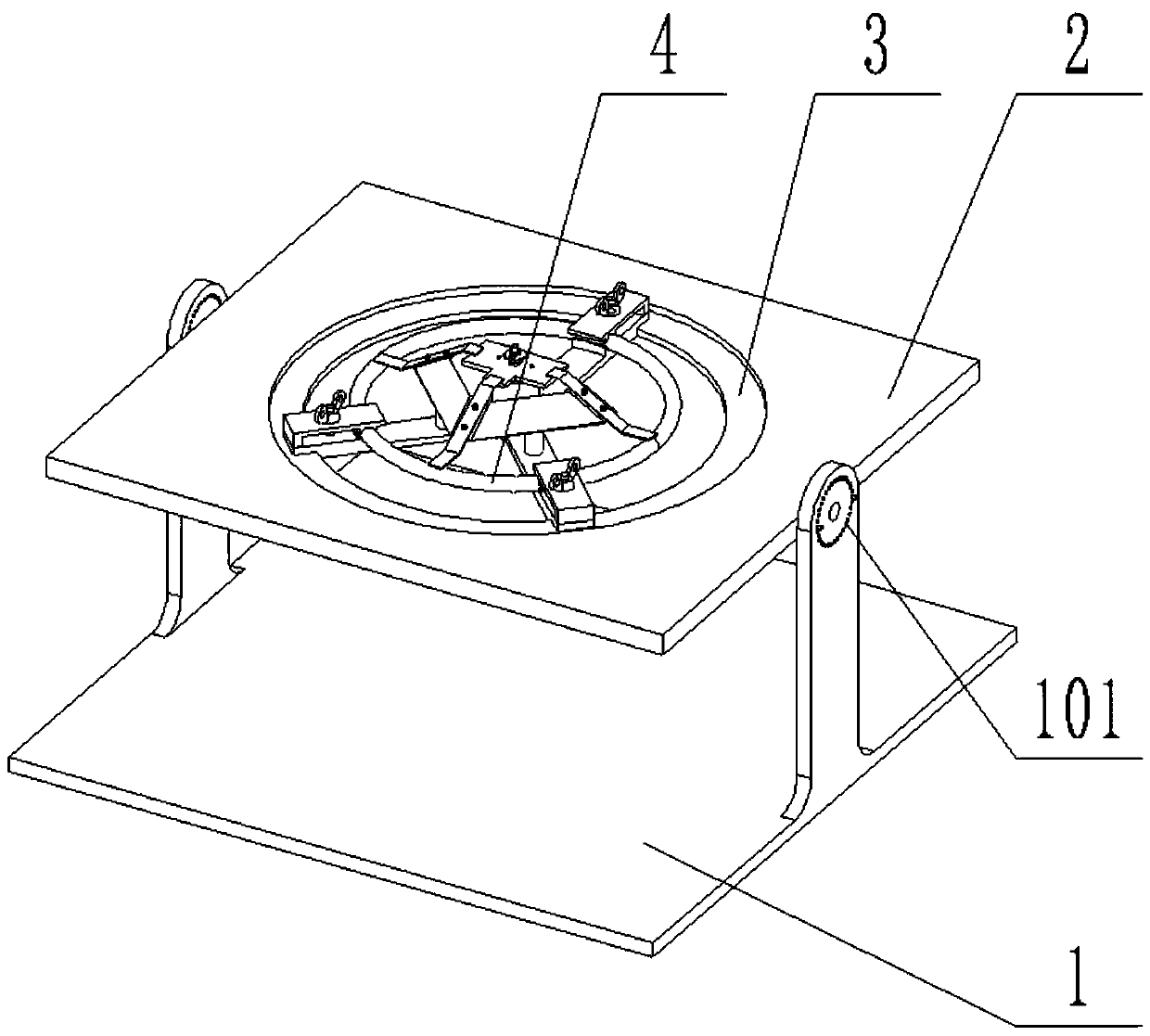

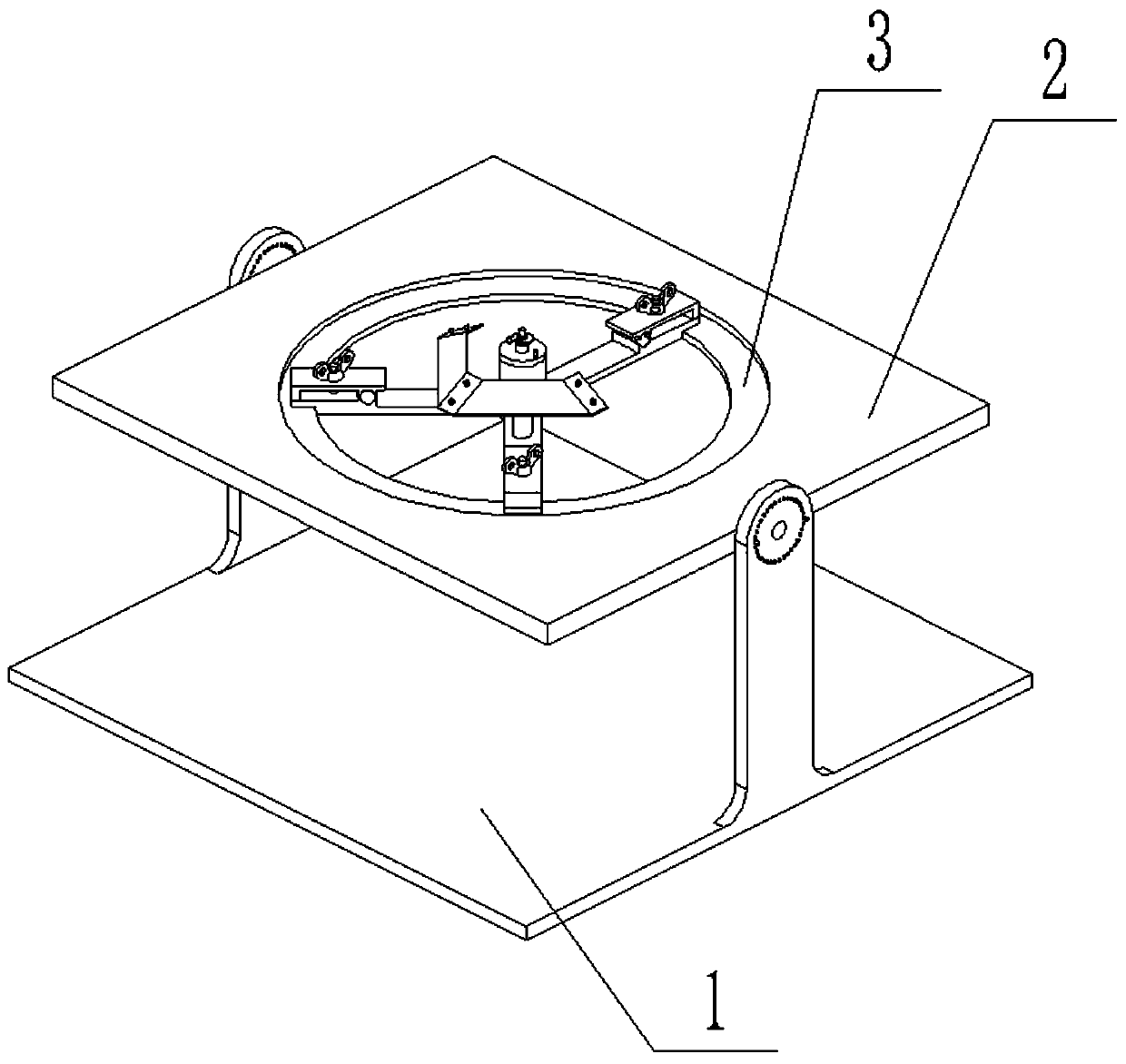

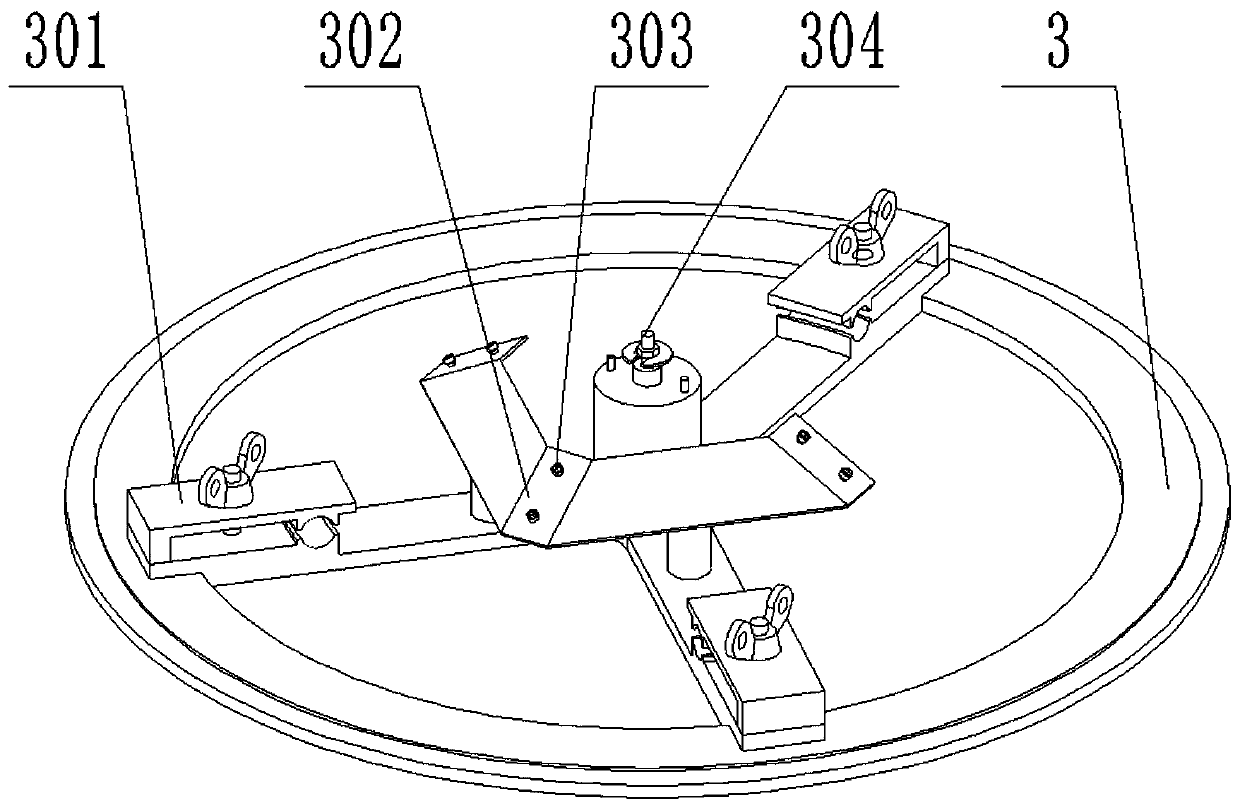

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The present invention provides a steering wheel frame assembly welding fixture, including a base 1, a positioning plate 101, a turning plate 2, a roller 201, a rotating mounting plate 3, an outer ring pressing plate 301, a web mounting plate 302, and a positioning screw pin 303 , quick-change gasket 304, steering wheel frame 4, steering wheel outer ring 401, steering wheel web 402 and steering wheel mounting plate 403; the top of the base 1 is axially connected with a set of turning discs 2; the middle of the turning disc 2 A set of rotating mounting plates 3 is axially connected; a set of steering wheel frame 4 is connected to the upper end surface of the rotating mounting plate 3; the steering wheel frame 4 is composed of the steering wheel outer ring 401, the steering wheel web 402 and the steering wheel mounting plate 403 constitute together.

[0029] Wherein, the left and right sides of the base 1 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com