Strain clamp for stranded carbon fiber composite core wire

A tension-resistant clamp and carbon fiber technology, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of non-adjustable crimping force, small grip force, and inability to meet the requirements of stranded carbon fiber composite core wire connection, fixing, and tensioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

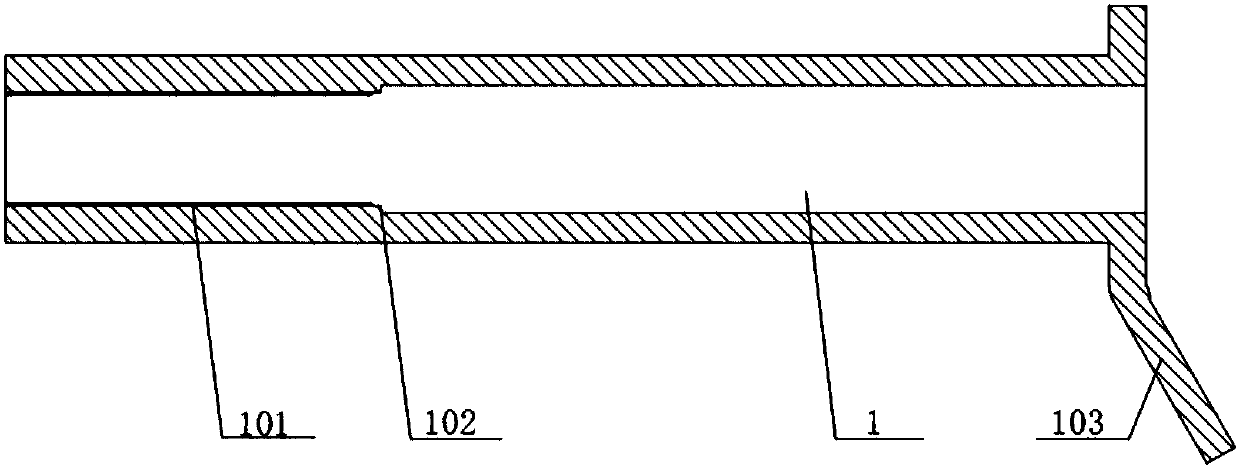

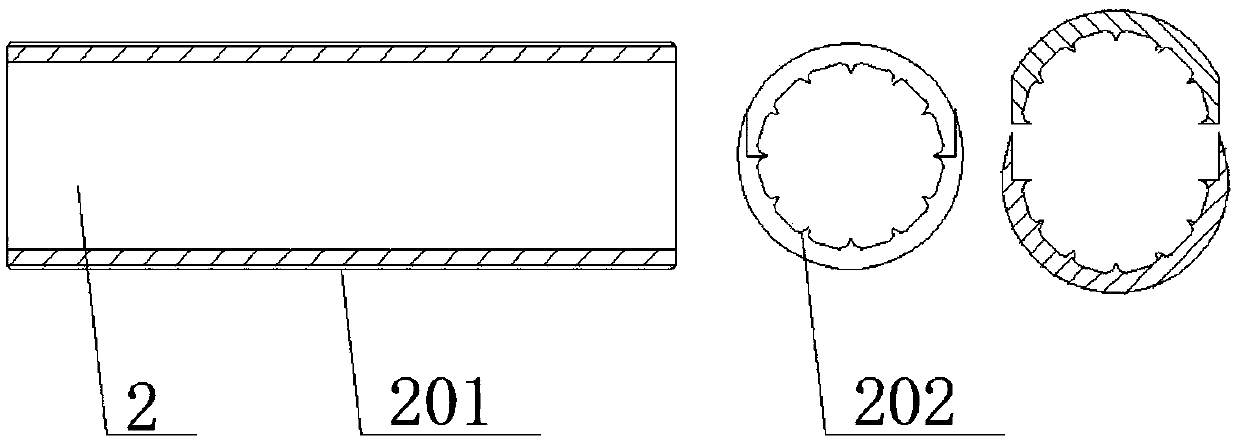

[0020] refer to figure 1 : Put the end of the stranded carbon fiber composite core wire (6) through the inner liner (2), and then through the tension clamp body (1); The large port of the clamp body is placed at the step (102) on its inner surface, which is used to block the inward movement of the composite carbon core protective tapered sleeve (4); next, pass the stranded carbon fiber composite core (7) through the central circular retaining ring (3) Then penetrate the stranded carbon core protective cone sleeve (4) to make the two closely match; then screw the tightly matched stranded carbon fiber composite core (7) and the stranded carbon core protective cone sleeve (4) into this A new type of steel anchor (5), which realizes tight fit through tapered threads, and realizes different The selection of the pressure value, so that the stranded carbon core protection tapered sleeve locks the stranded carbon fiber composite core; then move the end of the strain clamp body (1) wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com