Plastic bag folding and rubber band binding all-in-one machine

A plastic bag and all-in-one machine technology, which is applied to the parts and packaging of strapping machinery, can solve the problems of irregularity, slow falling speed, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

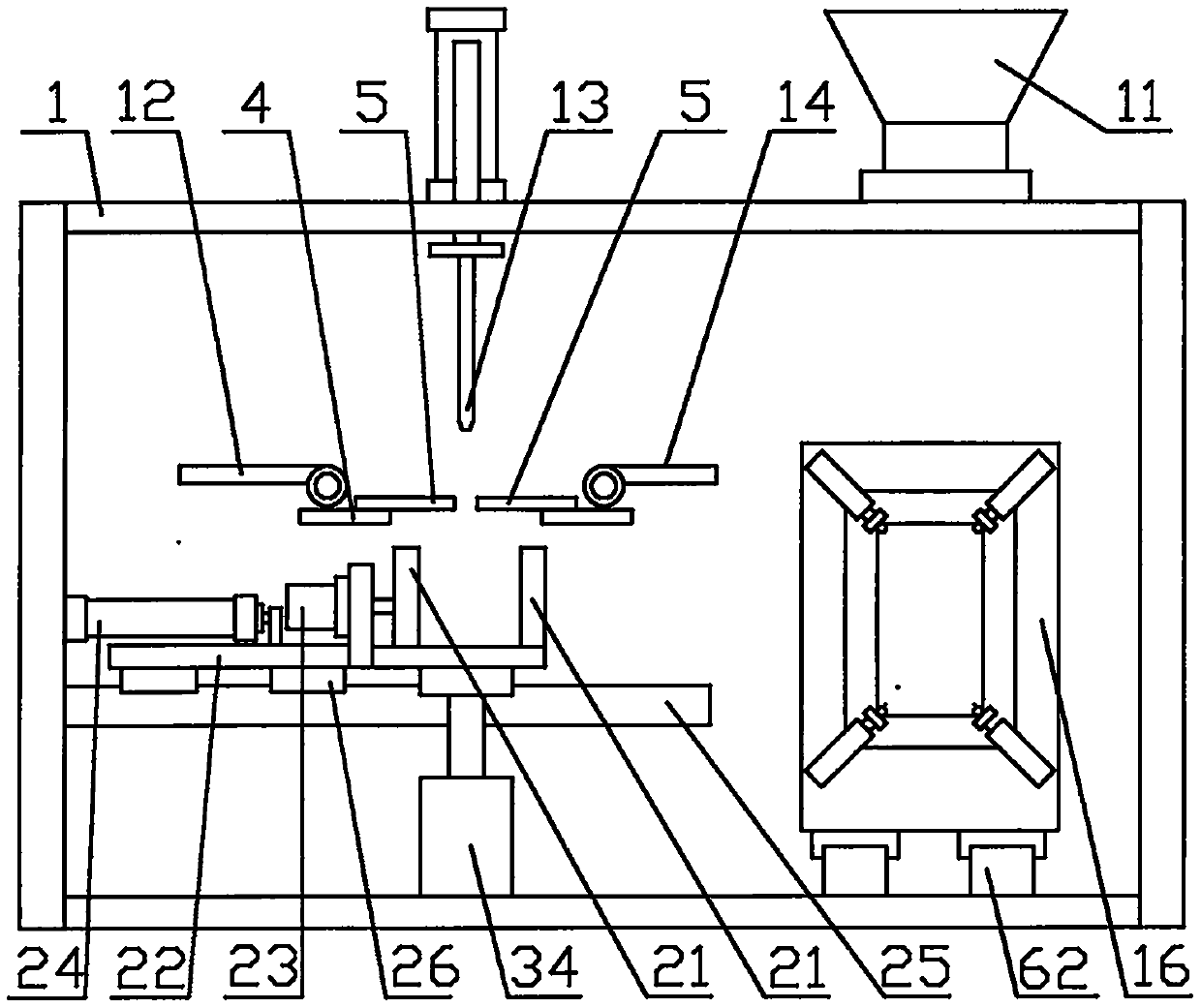

[0063] Embodiment one, such as Figure 1 to Figure 3 As shown: the handle folding device 2 includes a front corner folding mechanism, a trapezoidal front folding plate 21, and a pressure bag hook, and the tail folding device 4 is a rear folding plate 40 and a swing cylinder 41; the described The bag clamping device 5 and the bag holding device 6 include each other, including a splint cylinder 64, a lifting cylinder 61, a guide rod 62, and a beam 63; the bag passing movement device is connected with the bag holding device, that is, the bag passing movement device 7 Connect with the crossbeam 63 of the lifting drive mechanism of the bag holding device 6; the hanging bag clamping mechanism 55 includes two groups of bag clamping devices 5, wherein one group of bag clamping devices 5 is arranged on the frame 1 through the lifting drive mechanism, and the other group The bag clamping device 5 is connected on the bag passing movement device 7 through a lifting drive mechanism, and mo...

Embodiment 2

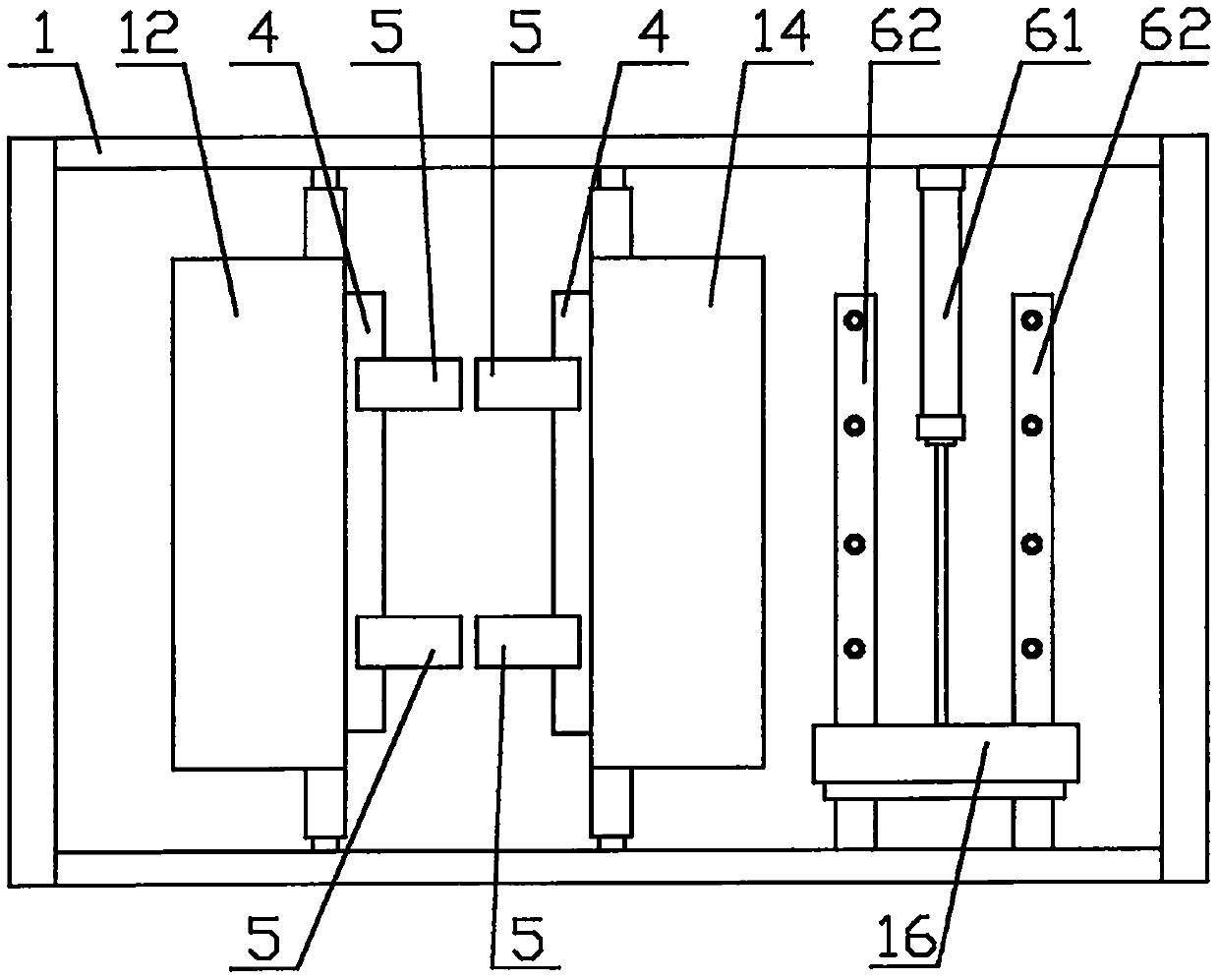

[0066] Embodiment two, such as Figure 11 to Figure 15 As shown, the difference between Embodiment 2 and Embodiment 1 is that two groups of bag clamping devices 5 are provided, one group of bag clamping devices 5 is connected to the bag passing movement device 7, and can follow the bag passing movement device. Movement, that is, the bag passing movement device 7 is connected with the bag clamping device 5; another group of bag clamping devices 5 is arranged on the frame 1 through the guide rod cylinder 59. The bag holding bar is a horizontal bar 60 arranged left and right;

[0067] like Figure 11 Shown: Install a guide rail 58 again on the rear portion of the guide rail 71, one side of the two splints 50 is slidably installed on the guide rail 58 through the slide block 57 respectively, and a clamping cylinder 56 is respectively installed at the front and rear ends of the guide rail 58 , the cylinder rods of the clamping cylinder 56 are respectively connected on the splint ...

Embodiment 3

[0069] Embodiment 3, the main difference between embodiment 3 and embodiment 1 is: firstly, the described bag clamping device is a kind of finger cylinder 52, and the bag holding rod of the described bag holding device 6 is a kind of interval setting The vertical rod 60; second, the handle folding device is a handbag folding mechanism composed of a bag holding board, a handle folding guide part, a left push plate, a right push plate, etc., please refer to the authorized publication number The utility model patent of CN208361536U is concretely implemented.

[0070] like Figure 16 , 17 Shown: 4 bag-holding rods 60 are set, so that the lower ends of the 4 bag-holding rods 60 are installed on a crossbeam 63 at intervals, above the crossbeam 63, the gap between the two bag-holding rods 60 on the left is forward Two slide blocks 72 are respectively installed front and back on the corresponding frame positions, two guide rails 71 are slidably installed on the slide block 72, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com