Fabricated tile mounting structure and construction process thereof

An installation structure and prefabricated technology, applied in the direction of building structure, floor, building, etc., can solve the problems of difficult adjustment of tile levelness, high operator requirements, tile cracks, etc., to achieve convenient flatness adjustment, convenient construction, The effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

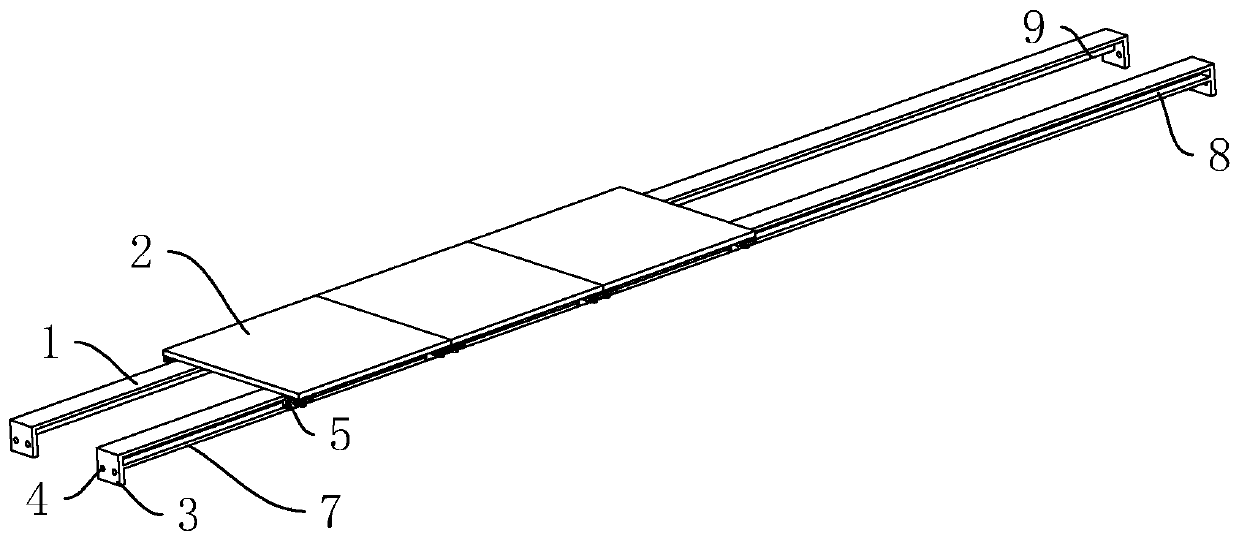

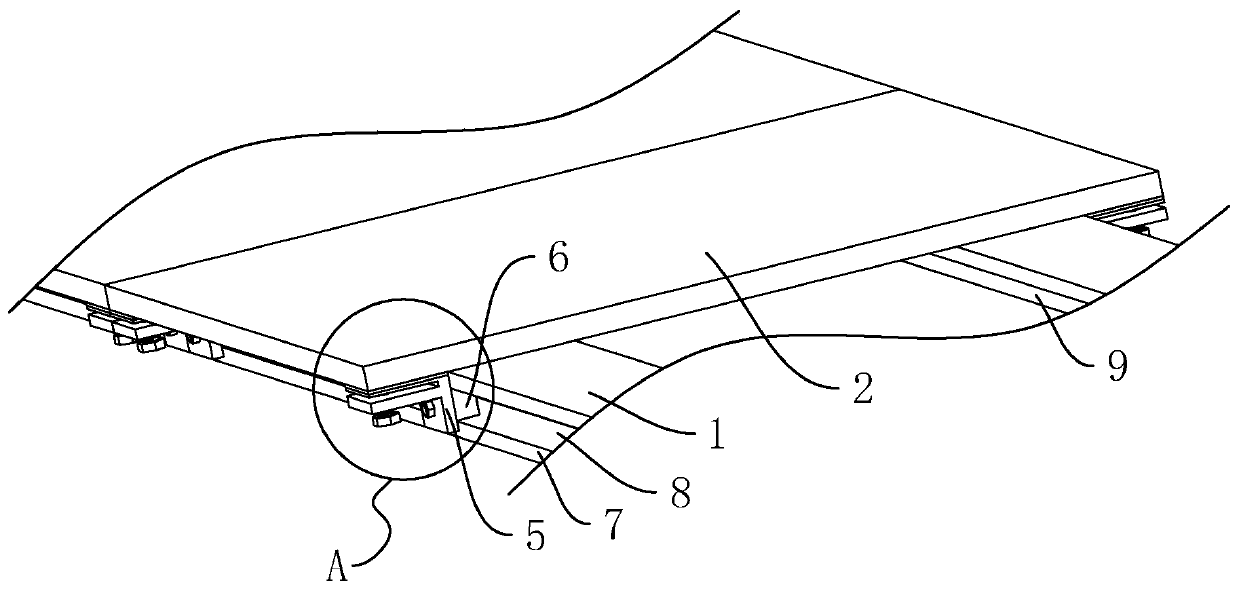

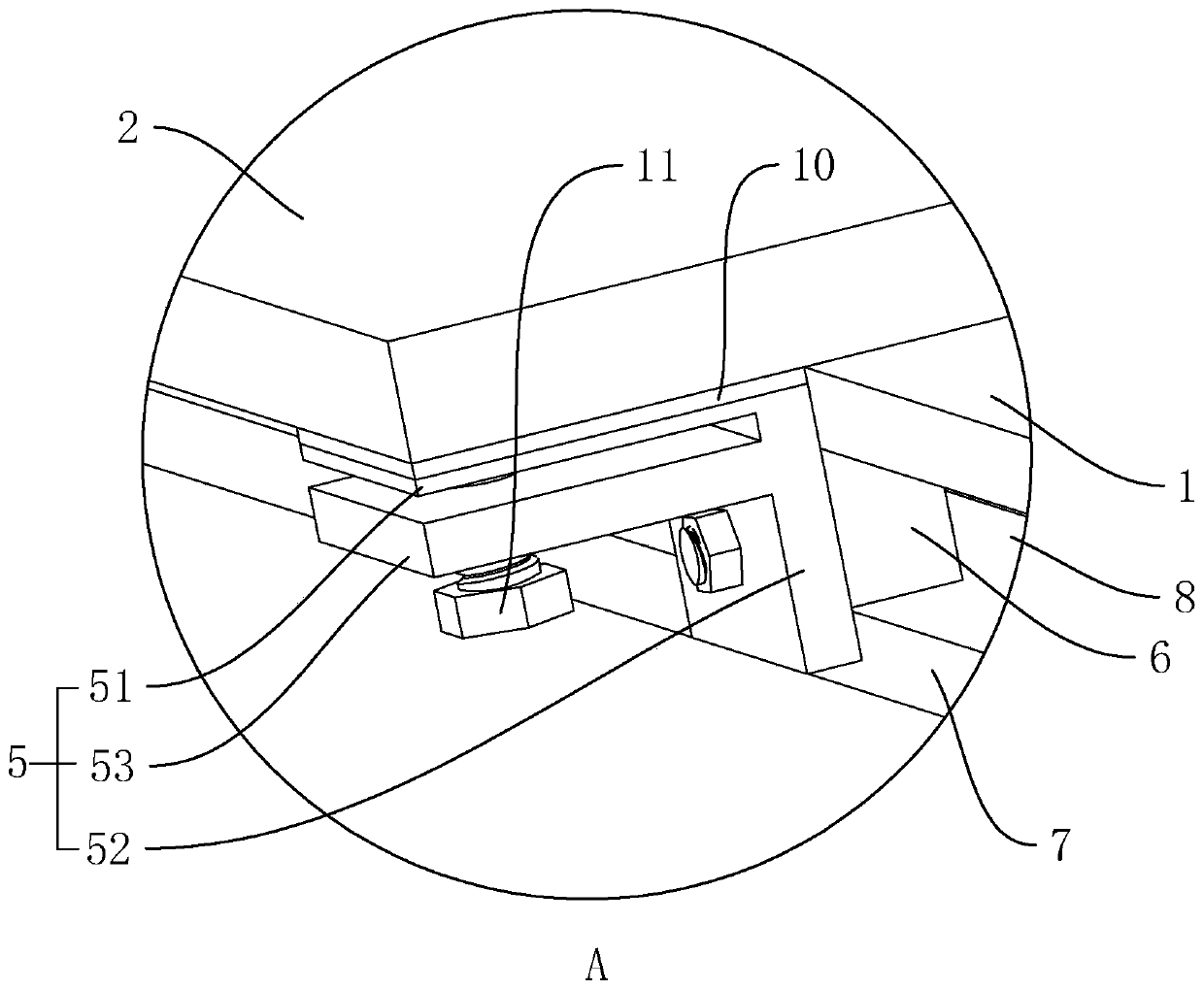

[0047] A prefabricated tile installation structure such as figure 1 As shown, it includes an installation board 1 and a tile board 2 laid on the installation board 1 . There are two mounting plates 1, and the two mounting plates 1 are parallel and symmetrically distributed. The tile boards 2 are arranged along the length direction of the installation board 1 , and each tile board 2 is arranged against the upper end surface of the installation board 1 . Both ends of each mounting plate 1 are provided with flanges 3, the flanges 3 extend in a direction away from the tile plate 2, and the flanges 3 are arranged perpendicular to the mounting plate 1, and the flanges 3 are correspondingly set There are through holes 4 .

[0048] When the installation board 1 is installed, the horizontal line is popped up on the wall through the ink line first, and then the installation board 1 is distributed along the horizontal line. During the installation of the installation board 1, the folde...

Embodiment 2

[0056] A construction technique for a prefabricated ceramic tile installation structure, such as Figure 5 shown, including the following steps:

[0057] S1: Play the horizontal line, through the ink line, pop up the horizontal line at the same height of the wall, usually the horizontal line is 15-25mm higher than the ground.

[0058] S2: Fix the installation board, fix the installation board 1 to the wall along the horizontal line through expansion bolts, set the flange 3 of the installation board 1 close to the ground, and set the installation board 1 according to the distance between the fixing seats 5 on the tile board 2 before fixing the installation board 1 The positions of a pair of mounting plates 1 are determined, and the distance between each pair of mounting plates 1 is set corresponding to the side length of the ceramic tile plate 2, so that the tiling of the ceramic tile plate 2 is more convenient. Usually, there is a gap between the installation board 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com