Auxiliary equipment for tower cylinder accessory horizontal type mounting as well as tower cylinder accessory horizontal type mounting method

A technology of auxiliary equipment and installation method, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of unguaranteed personnel safety, labor consumption, poor safety, etc., to reduce personnel and financial resources, reduce economic losses, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

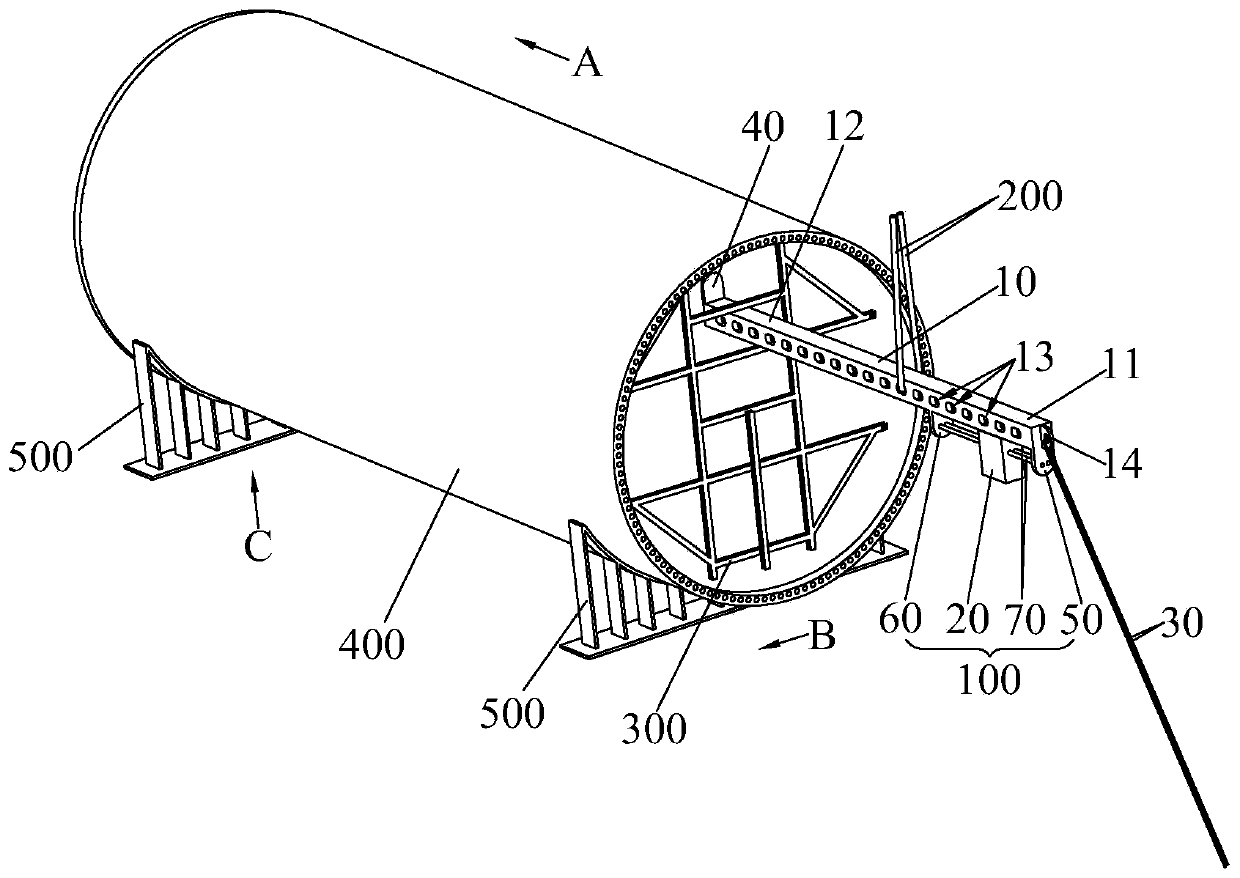

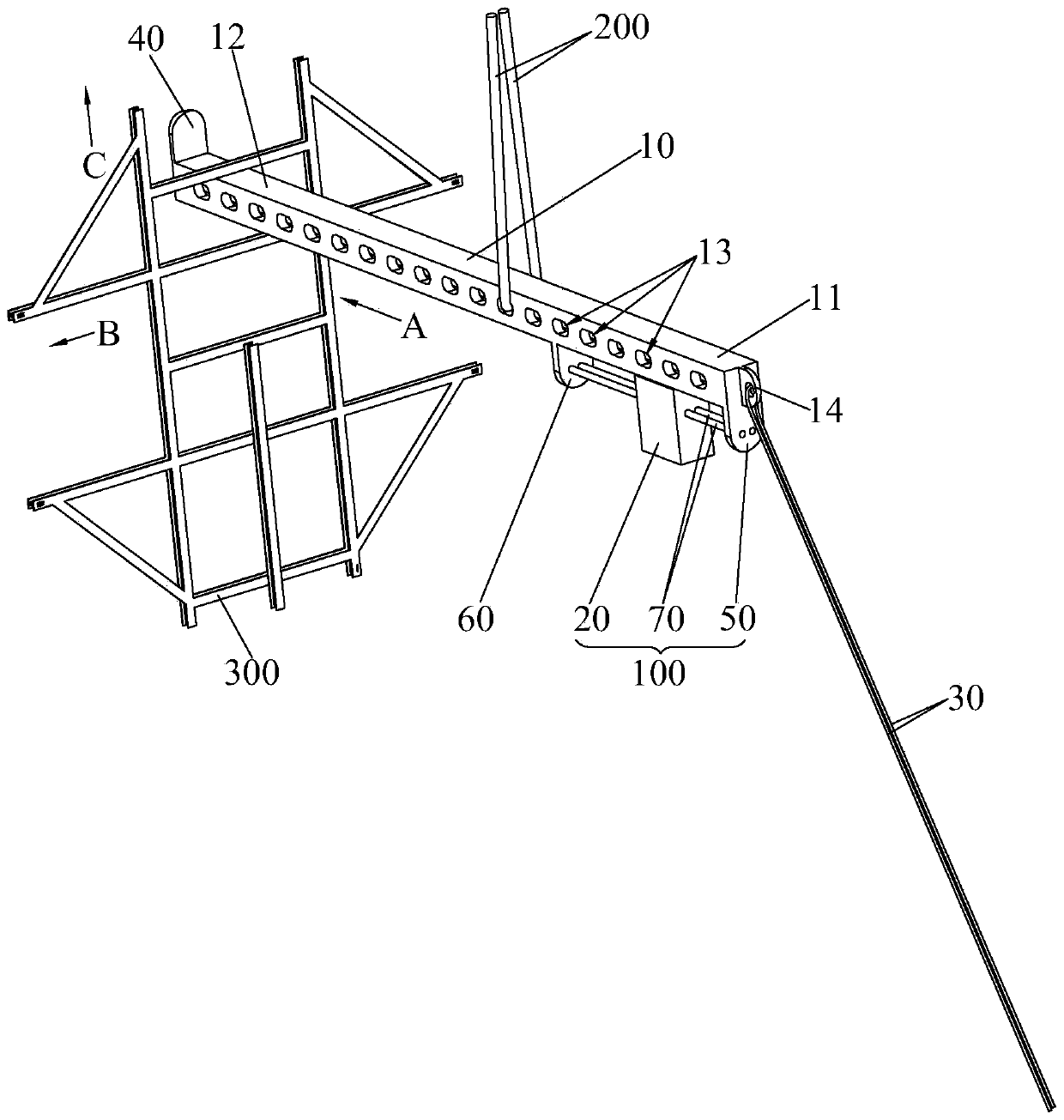

[0029] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0030] see Figure 1 to Figure 3 , the auxiliary equipment 100 for horizontal installation of tower accessories of the present invention is used to assist in sending the accessories 300 to be installed into the horizontally placed wind power tower 400, and the wind power tower 400 is suspended on the ground by means of the tower bearing frame 500, In order to ensure the reliability of the wind power tower 400 hanging on the ground; preferably, there are two tower bearing frames 500 and they are respectively arranged at the two axial ends of the wind power tower 400, so that the wind power tower 400 is more Reliably suspended on the ground, of course, according to the actual situation, the number of the tower bearing frame 500 can also be three, four or five, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com