Drop reliability test device

A test device and reliability technology, applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problem of not being able to meet the drop of the teach pendant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make those skilled in the art better understand the technical solutions of the present application, the present application will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present application. .

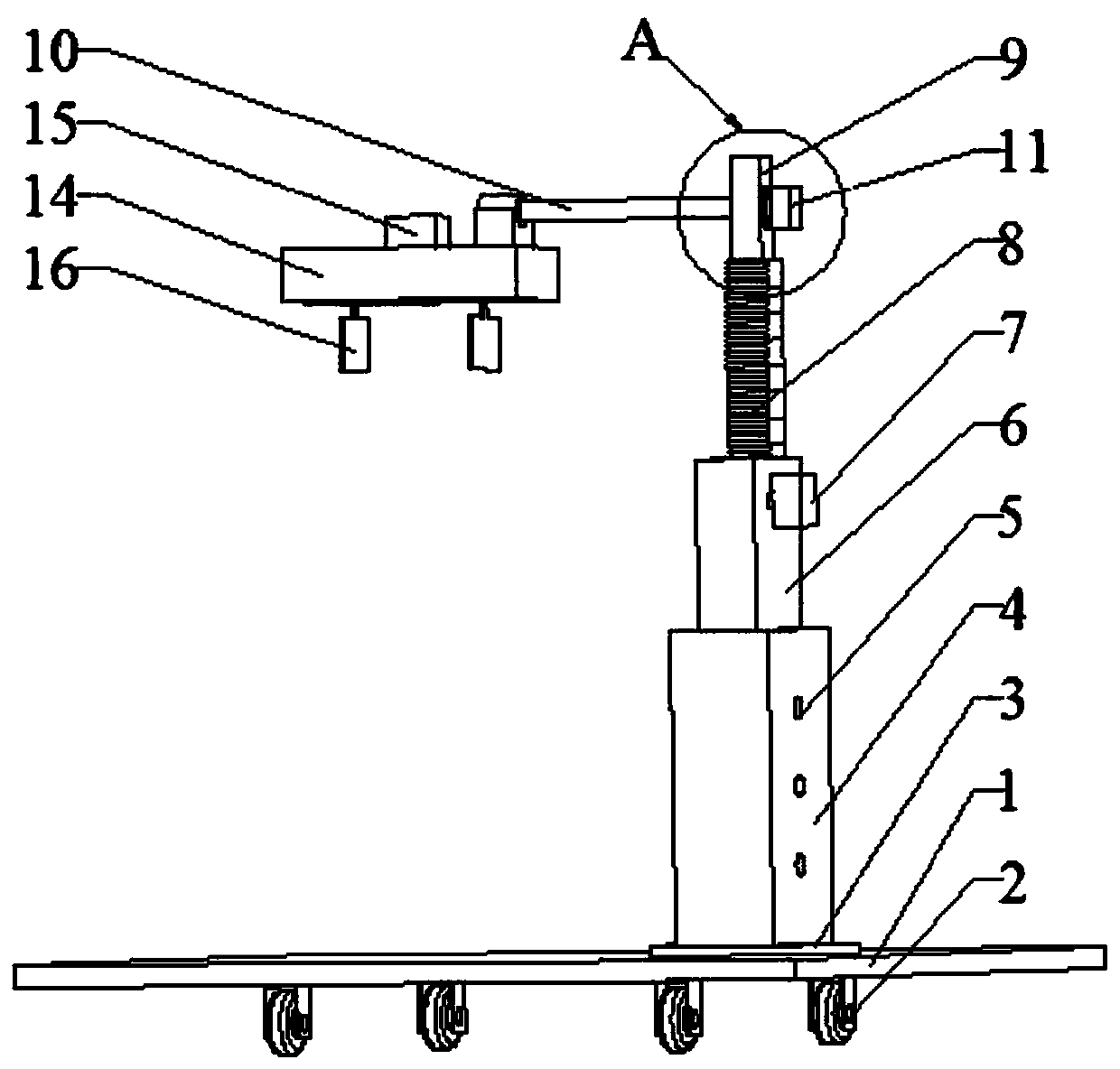

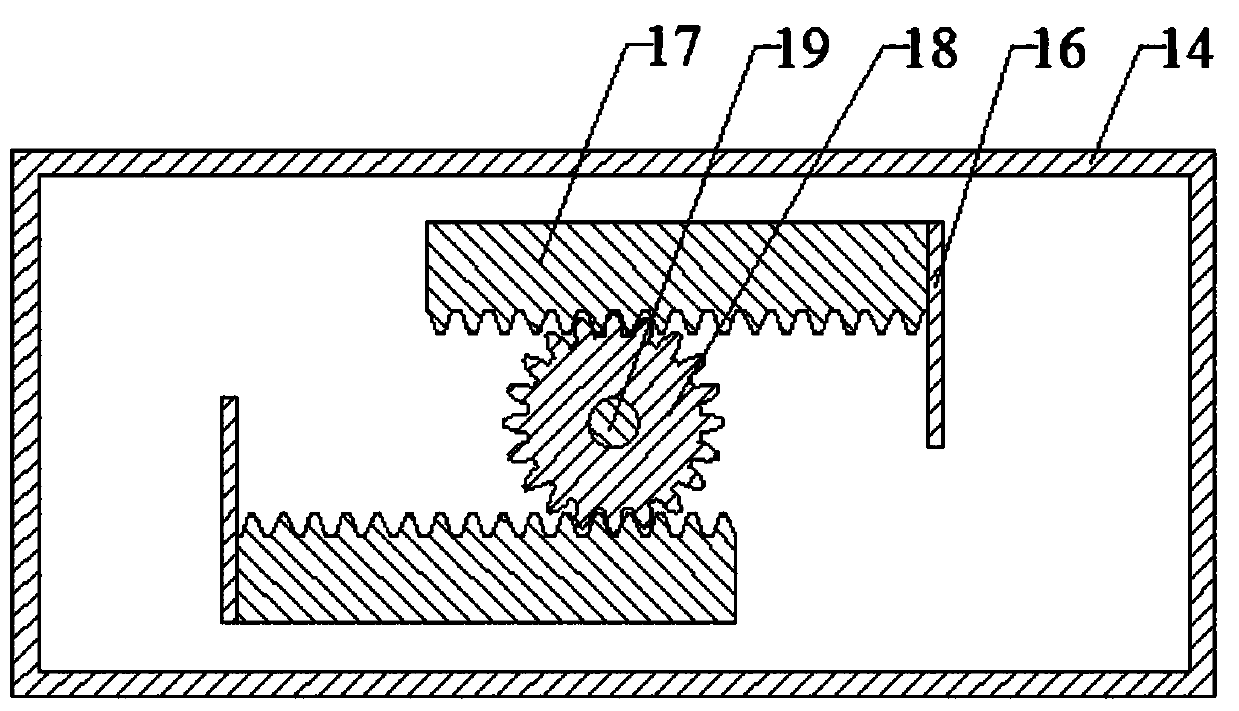

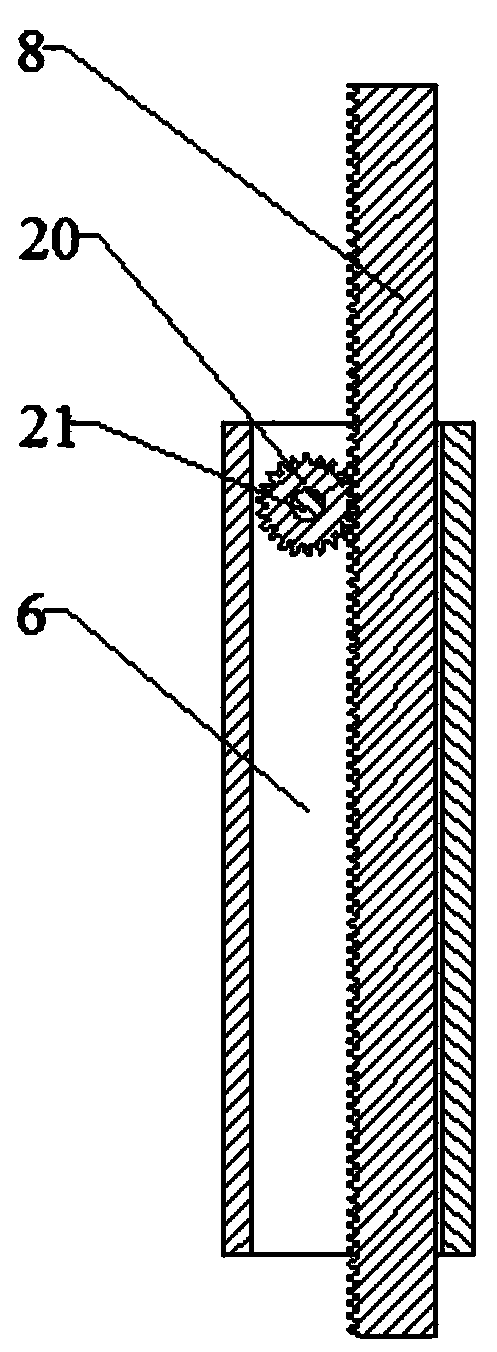

[0022] like figure 1 As shown, this embodiment provides a drop reliability test device, including a clamping mechanism for fixing / releasing an industrial robot teach pendant and a drop height adjustment mechanism for adjusting the drop height; the clamping mechanism can be adjusted through the rotating shaft 10 It is rotatably connected to the drop height adjustment mechanism to adjust the drop angle of the industrial robot teach pendant; the clamping mechanism is provided with a pair of clamping plates 16, the connecting line of the pair of clamps 16 is parallel to the rotating shaft 10, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com